In the world of modern farming, machines play a crucial role in improving efficiency and productivity. Each piece of equipment consists of numerous interconnected elements that enable smooth operation. Knowing how these individual components work together is essential for anyone looking to maintain or repair agricultural machinery.

To ensure that your machinery runs efficiently, it’s important to understand the design and function of the various mechanical systems. From the engine to the drive mechanisms, each component has a specific purpose that contributes to the overall performance. Familiarity with these systems helps operators troubleshoot issues, perform routine maintenance, and enhance the lifespan of the equipment.

Through proper analysis and a thorough understanding of each mechanical section, farmers can address potential problems before they become major issues. Recognizing the importance of these internal systems will ultimately lead to better care, reduced downtime, and increased productivity in the field.

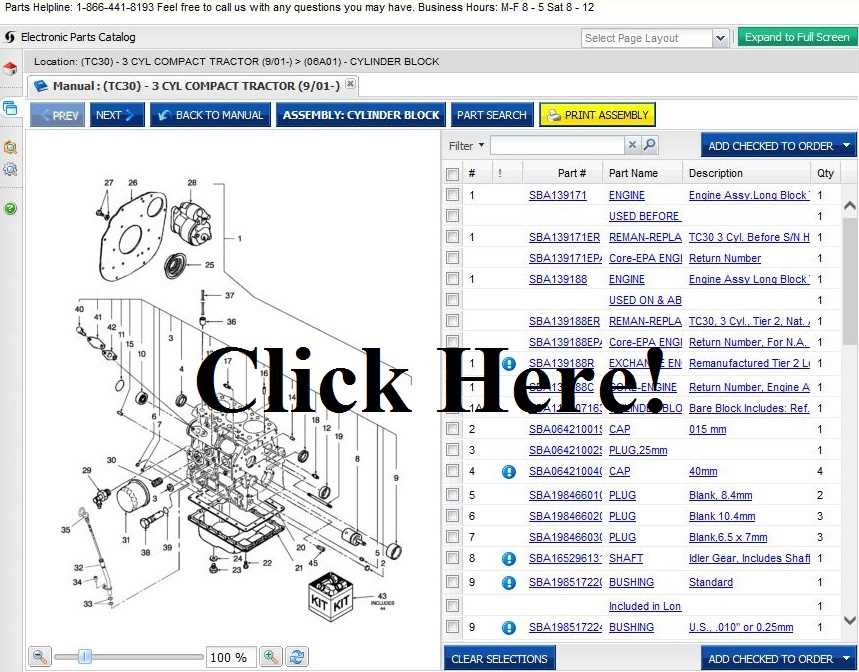

Key Components of Tractor Diagrams

Understanding the structure of agricultural machinery is essential for effective operation and maintenance. These machines are made up of various essential elements that work together to ensure optimal performance. Each system is designed to fulfill a specific function, and a clear understanding of these components helps operators recognize potential issues and address them quickly.

Engine and Powertrain

The engine serves as the heart of the machine, providing the necessary power to drive all other systems. The powertrain, which includes the transmission and driveline components, is responsible for transferring power from the engine to the wheels or other attachments. Understanding the interaction between these elements is crucial for diagnosing performance issues and maintaining engine efficiency.

Hydraulic and Control Systems

Hydraulic systems enable heavy lifting, steering, and other vital tasks by using fluid pressure to power various components. These systems are often interconnected with control units, allowing the operator to manage different functions. Proper knowledge of the hydraulic circuits and control mechanisms helps in troubleshooting and optimizing performance for different farming tasks.

Understanding Tractor Engine and Transmission Parts

The engine and transmission systems are the core of any farming machine, providing the necessary power for various operations. These systems are intricately designed to work in unison, ensuring that the equipment performs efficiently under various conditions. A clear understanding of their components and functionality is essential for troubleshooting, maintenance, and improving overall machine longevity.

The engine is responsible for generating the power needed to perform tasks such as plowing, tilling, and hauling. It consists of various internal mechanisms, including cylinders, pistons, and a fuel system, which work together to produce energy. Efficient performance depends on the proper functioning of each element, with any malfunction potentially leading to a significant drop in power output.

Equally important is the transmission system, which transmits the engine’s power to the wheels or other attachments. This system is responsible for controlling the speed and torque, enabling the machine to adapt to different tasks. Whether it’s a manual gearbox or an automatic system, understanding how the transmission operates helps in making adjustments and repairs when needed.

How Tractor Diagrams Aid in Maintenance

Effective maintenance of agricultural machinery relies on a clear understanding of its internal structure and systems. Visual representations of these systems serve as a valuable tool for operators, helping them identify and address issues efficiently. By providing a detailed overview of the various components, these resources enable users to perform routine checks, spot potential problems, and understand how to resolve them.

Having access to a well-structured schematic allows for quicker diagnosis of mechanical failures. When issues arise, operators can trace specific components and follow step-by-step guides to pinpoint the cause. This knowledge not only speeds up repairs but also prevents unnecessary damage by ensuring that maintenance tasks are performed correctly. Moreover, these guides help operators follow recommended procedures, preserving the integrity of the machinery.