Maintaining and repairing complex machinery requires a solid understanding of its internal structure and how each element functions. A comprehensive map of these components can be an invaluable tool for both seasoned operators and beginners alike. This guide will help you familiarize yourself with the essential parts that make up these heavy-duty machines and their interconnections.

By referring to a detailed illustration, you can easily identify the individual elements, understand their purpose, and identify potential issues during routine checks. Whether you are troubleshooting or performing regular maintenance, knowing how to navigate this visual guide will significantly improve your efficiency and reduce downtime.

Zetor Tractor Parts Overview

In every heavy-duty machine, understanding the key components is essential for smooth operation and long-lasting performance. These machines are made up of several interconnected systems, each with its own role in ensuring proper functionality. From the engine to the frame, each element contributes to the overall efficiency.

Each system contains a variety of individual parts, all working together to provide power, stability, and control. Knowing the main groups of components helps you recognize their purpose and troubleshoot any issues more effectively.

- Power Unit: This system is responsible for generating and distributing the energy needed to operate the machine.

- Transmission: The transmission controls the power flow, helping the machine adapt to different speeds and workloads.

- Steering Mechanism: Essential for controlling direction and ensuring maneuverability in various terrains.

- Hydraulic System: This system uses fluid power to assist with lifting, digging, and other operations.

- Cooling and Exhaust Systems: Vital for maintaining optimal engine temperature and directing emissions away from the operating area.

- Frame and Suspension: These provide the structural integrity and stability needed for heavy lifting and rough terrain operation.

Each component plays a critical role in the overall performance and reliability of the equipment. Understanding how these systems and elements interact is key to maintaining efficient operation and preventing breakdowns.

How to Read a Zetor Parts Diagram

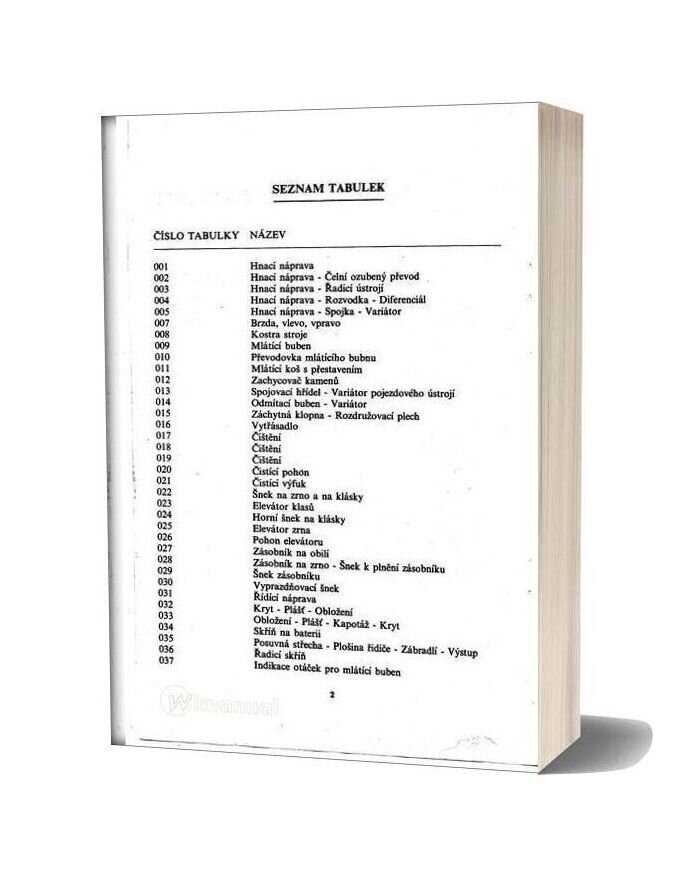

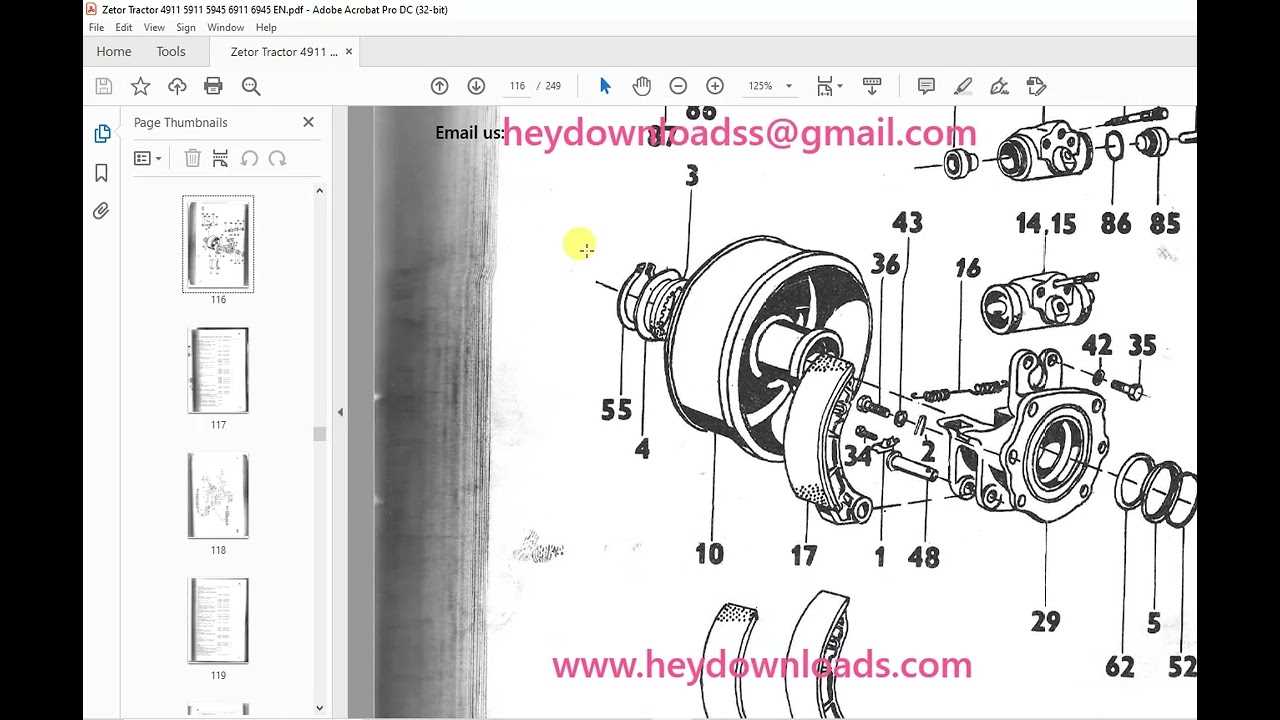

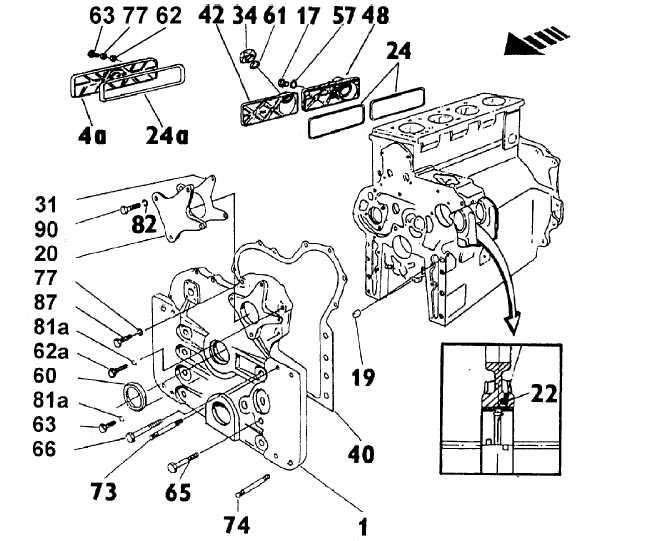

Understanding how to interpret visual schematics is essential when working with complex machinery. These illustrations provide a clear and detailed representation of the internal structure, showing how each element fits into the larger system. By learning to read these diagrams effectively, you can easily identify and troubleshoot problems, as well as understand the relationship between different components.

Familiarize Yourself with the Symbols

Every diagram uses a set of standard symbols to represent specific components. It’s crucial to familiarize yourself with these visual cues before attempting to read the schematic. Each symbol corresponds to a particular part, such as the engine, transmission, or hydraulic systems. Understanding what these symbols mean will make interpreting the diagram more straightforward.

Follow the Flow of Connections

In these visual guides, the lines connecting the symbols represent the flow of power or fluid between different elements. By following these lines, you can trace how the systems work together. Pay attention to how parts are interconnected to ensure efficient operation and identify potential issues.

Common Zetor Tractor Part Replacements

Regular maintenance and timely replacements are crucial to keep machinery running efficiently. Over time, certain components experience wear and tear due to continuous use and exposure to harsh conditions. Knowing which parts are most commonly replaced allows for proactive maintenance and minimizes downtime.

One of the most frequently replaced elements in these machines is the air filter, which ensures proper airflow to the engine. A clogged filter can reduce performance and damage internal components. Fuel filters also require periodic replacement to prevent contaminants from entering the engine and causing damage.

- Belts and Chains: These parts often wear out due to friction and need to be replaced regularly to ensure proper operation of the moving parts.

- Brake Components: Brakes undergo constant stress, making brake pads and discs among the most commonly replaced parts.

- Hydraulic Seals: Leaking seals in the hydraulic system can cause loss of pressure, leading to inefficiency and potential failure of the system.

- Battery: Over time, batteries lose their capacity to hold a charge and must be replaced to avoid starting issues.

Staying ahead of these common replacements ensures the equipment runs smoothly and reduces the likelihood of unexpected breakdowns during operation.