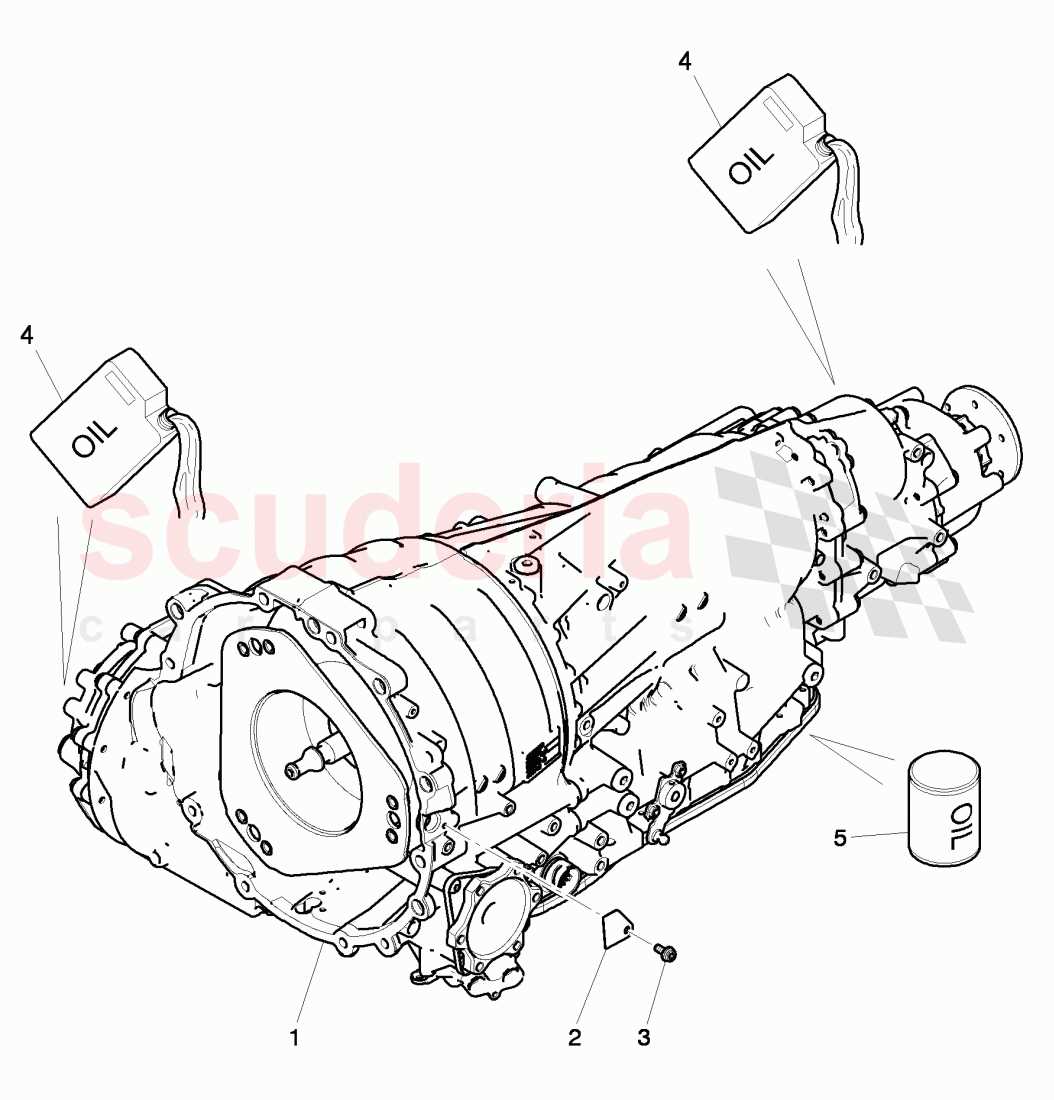

When exploring the inner workings of a vehicle’s drive system, it is essential to understand how the various elements function together to provide smooth shifting and optimal performance. The complex system consists of multiple components that enable the vehicle to transition between gears efficiently. Each piece plays a critical role in the overall operation, and understanding their interaction is key to diagnosing issues and ensuring longevity.

Mechanical and hydraulic elements within the system work in harmony to deliver power from the engine to the wheels. While many may not be familiar with the specifics of these systems, they are crucial for maintaining proper vehicle operation. Regular maintenance and understanding of how these systems interact can help prevent costly repairs.

Identifying common issues within the system can also be aided by recognizing the signs of wear or failure in individual components. Knowing how to troubleshoot and when to seek professional help can save time, money, and avoid unnecessary complications in the future.

Understanding Vehicle Gear Mechanism Components

The smooth operation of a vehicle’s shifting system relies on the precise coordination of its various elements. These components work together to ensure seamless gear changes, providing both power and efficiency. Each individual component plays a specific role in maintaining the overall system’s functionality, and understanding their functions can help in diagnosing issues and ensuring proper maintenance.

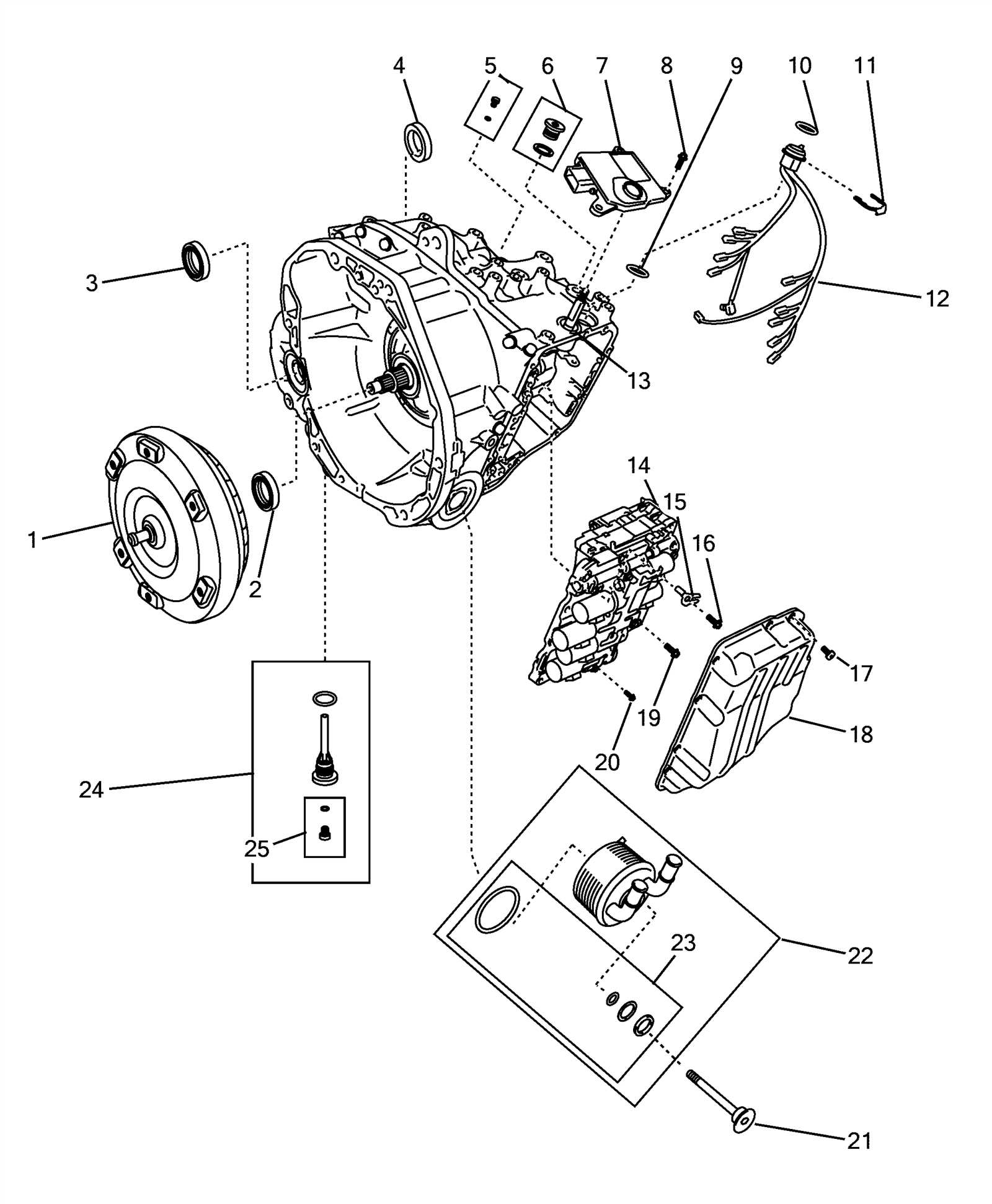

Key Elements of the Gear System

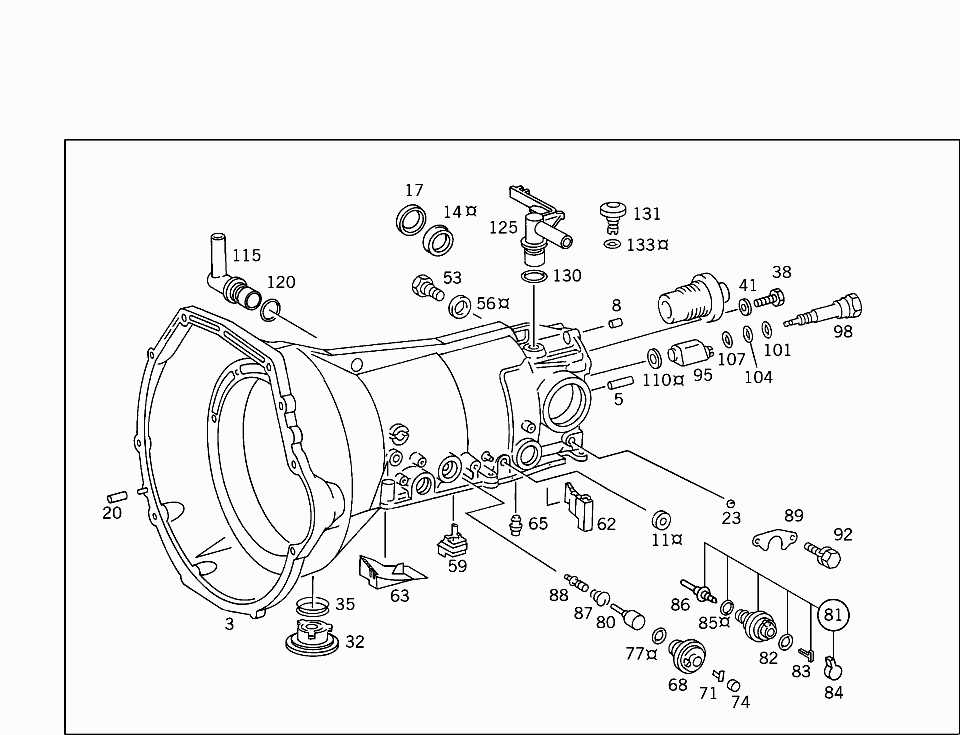

At the core of the system are the gears themselves, which vary in size and function depending on the desired output. These gears are engaged and disengaged by the system’s hydraulic and mechanical components, ensuring the correct amount of torque is transferred to the wheels. The role of fluid pressure and hydraulics is integral, as they control the engagement of the gears at the appropriate times.

Maintaining System Efficiency

Proper lubrication and the efficient flow of hydraulic fluid are essential for maintaining the longevity and functionality of the system. Regular checks and replacement of fluid ensure that the components do not wear prematurely, while monitoring other elements like seals and sensors helps prevent leaks and malfunctions. Understanding the role of each component can make a significant difference when troubleshooting issues or performing routine maintenance.

How Gear Mechanism Components Work Together

The efficiency of a vehicle’s gear system depends on the collaboration of various elements that interact seamlessly to ensure smooth transitions between speeds. These components rely on both mechanical and hydraulic forces to transfer power from the engine to the wheels. Understanding how they cooperate allows for a better understanding of vehicle performance and maintenance requirements.

Hydraulic systems play a crucial role by controlling the pressure needed to engage and disengage the different components at the right time. This precise control ensures that gears mesh correctly, avoiding slipping or harsh shifting. Meanwhile, mechanical elements, such as clutches and linkages, act as the bridge between the engine’s power and the wheels’ movement, providing necessary torque when required.

Sensors and electronic systems have become essential in modern vehicles, enhancing communication between the hydraulic and mechanical components. They ensure that the system responds accurately to driving conditions, making real-time adjustments to optimize the performance and fuel efficiency of the vehicle.

Common Issues with Gear Mechanism Components

While the gear system is designed for durability and efficiency, several issues can arise over time, leading to poor performance and potential breakdowns. These problems often stem from wear and tear, improper fluid levels, or malfunctioning components that disrupt the smooth functioning of the entire system. Recognizing the signs of these issues early can prevent more significant damage and costly repairs.

Fluid and Hydraulic Failures

One of the most common problems in a vehicle’s shifting system is inadequate fluid levels or contamination. Low or dirty fluid can lead to improper hydraulic pressure, affecting gear engagement and causing delays or harsh shifts. It is essential to regularly check and replace fluid to ensure smooth operation and prevent wear on seals and valves.

Mechanical Wear and Tear

Over time, mechanical components such as clutches, gears, and bearings can wear down due to constant use. This wear can cause slipping, grinding noises, or difficulty shifting between gears. Proper maintenance and timely replacement of these parts can help avoid sudden failures and maintain the vehicle’s overall performance.