In every vehicle, the system responsible for transmitting power from the engine to the wheels consists of multiple crucial components working together. These elements are carefully designed to ensure smooth operation, enabling the driver to control speed and efficiency. The interaction between these pieces of machinery is complex but vital for optimal vehicle performance.

Familiarity with how these components are structured and function can significantly improve the understanding of vehicle mechanics. Knowing the roles of each component helps in both troubleshooting and regular maintenance. The following section provides an overview of the essential mechanisms within this system and how they interact to create a seamless driving experience.

Understanding Manual Transmission Components

In vehicles, a critical system is responsible for controlling the vehicle’s speed and movement through the precise engagement of mechanical elements. These components work together to ensure the engine’s power is effectively transferred to the wheels. The ability to shift between different speeds relies on a series of interlocking parts, each fulfilling a specific function.

Key Components and Their Functions

One of the most essential components in this system is the gear mechanism, which allows the driver to change the vehicle’s speed. The gears work in tandem with the clutch to control power flow, enabling the driver to smoothly transition between different speeds. Additionally, the shifter assembly provides the means for the driver to manually engage the correct gear, giving full control over the driving experience.

How These Elements Interact

For the system to function efficiently, each component must work in harmony with the others. The flywheel, for instance, is crucial in maintaining momentum and ensuring a smooth start and stop of the vehicle. Without the proper interaction between these elements, driving would become jerky and unreliable. Proper maintenance and understanding of how these components function together can greatly enhance the longevity and performance of the entire system.

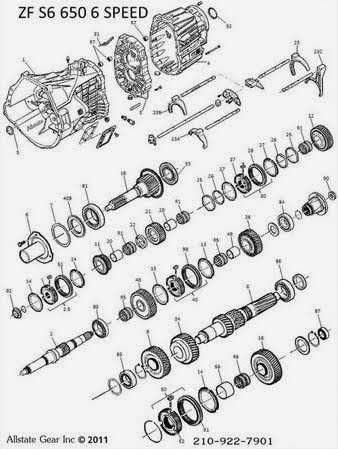

How Gears Function in Manual Transmissions

Gears play a fundamental role in controlling the speed and torque of a vehicle, allowing the driver to adjust power based on driving conditions. The process involves meshing different sized gears that alter the engine’s output before it reaches the wheels. This adjustment enables smooth acceleration and deceleration while providing the necessary force to move the vehicle at varying speeds.

Engagement and Gear Shifting

When the driver selects a specific gear, a series of gear teeth mesh together to either increase or decrease the rotation speed. The larger gears produce more torque at slower speeds, while smaller gears increase speed but reduce torque. The engagement of these gears is controlled by the clutch system, which temporarily disconnects the engine from the gears, allowing the driver to smoothly shift between speeds without causing damage to the system.

The Role of Synchronizers

To ensure a smooth transition between gears, syncros are used to match the speed of the gears before they engage. This helps eliminate grinding and ensures that the driver can change gears without resistance. These components are essential in providing a seamless and efficient shifting experience, allowing the driver to focus on controlling the vehicle while the internal mechanisms handle the power management.

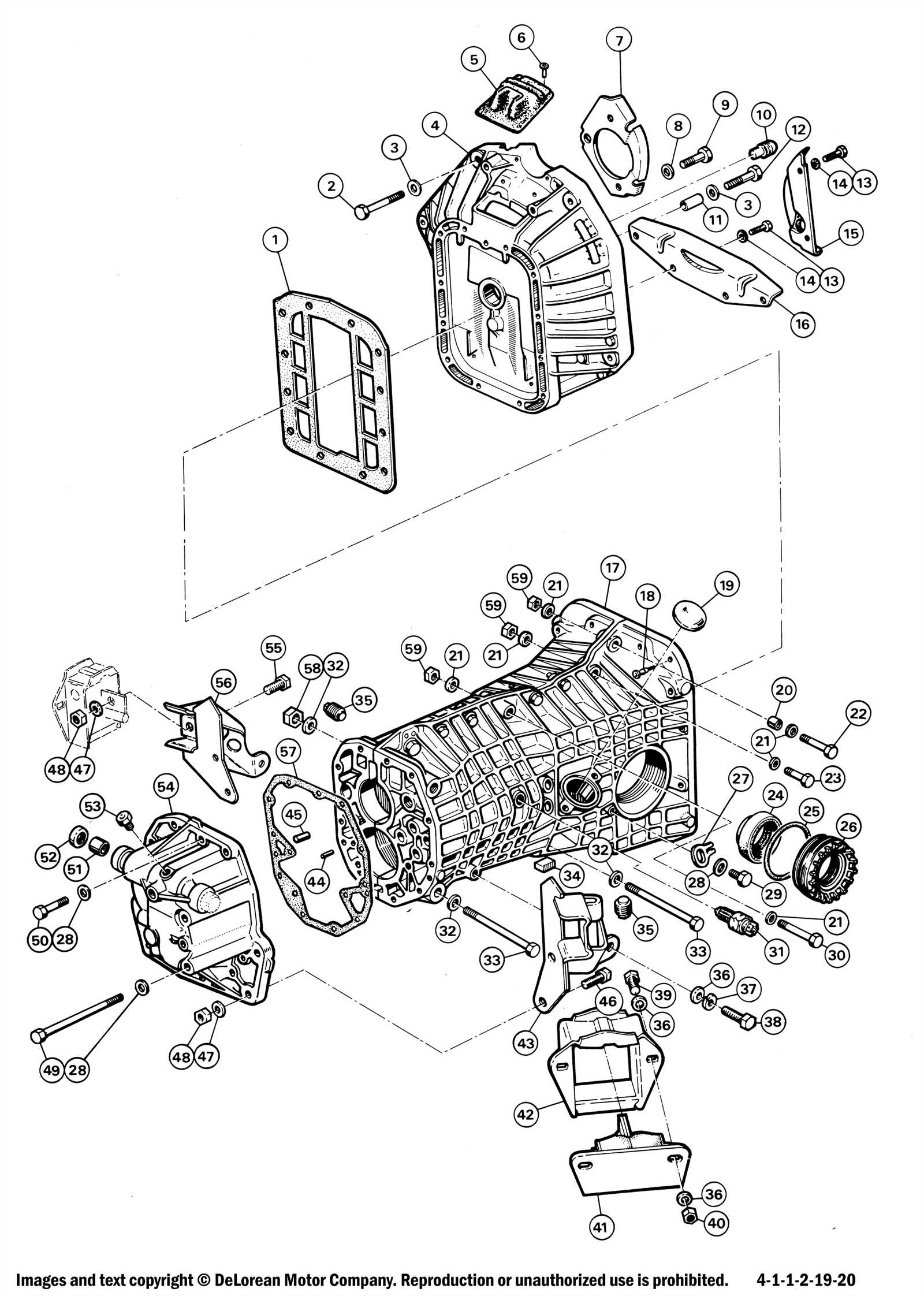

Detailed Diagram of Transmission Parts

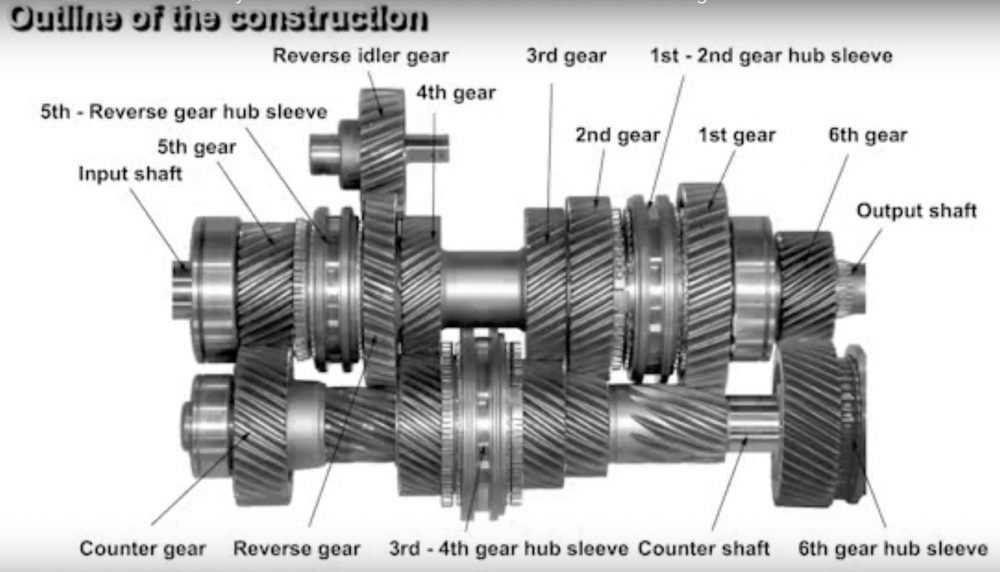

The system responsible for controlling the speed and power flow in a vehicle consists of a variety of interconnected components, each with a unique role. These elements work together to ensure the smooth transfer of energy from the engine to the wheels, allowing the vehicle to accelerate, decelerate, and maintain a steady speed. Understanding the layout of these components helps provide a clearer picture of how each part contributes to the vehicle’s overall performance.

From the gear selectors that allow the driver to manually shift to the clutch assembly that temporarily disengages the engine, every element plays an integral part in the driving experience. The input shaft transfers rotational motion from the engine, while the output shaft delivers it to the wheels. Alongside these, the countershaft serves as a key intermediary, ensuring the right torque and speed are achieved. Together, these components form a cohesive system that ensures optimal power distribution and smooth operation.

Key Parts and Their Roles in Operation

The efficient functioning of a vehicle’s power management system relies on the precise interaction of several crucial components. These elements work in tandem to regulate speed, torque, and the overall performance of the vehicle. Understanding the role of each part is vital for proper maintenance and troubleshooting.

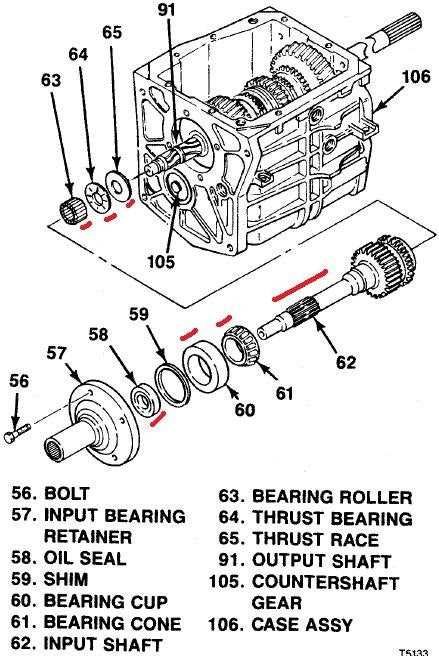

Critical Components and Their Functions

- Clutch: Engages and disengages the engine from the system, allowing the driver to change gears smoothly.

- Gear Mechanism: Changes the power output by shifting between different speeds and torque levels.

- Input Shaft: Transfers rotational motion from the engine to the gears.

- Output Shaft: Delivers the final power output to the wheels, controlling vehicle movement.

- Countershaft: Serves as an intermediary, adjusting power flow between gears for optimal performance.

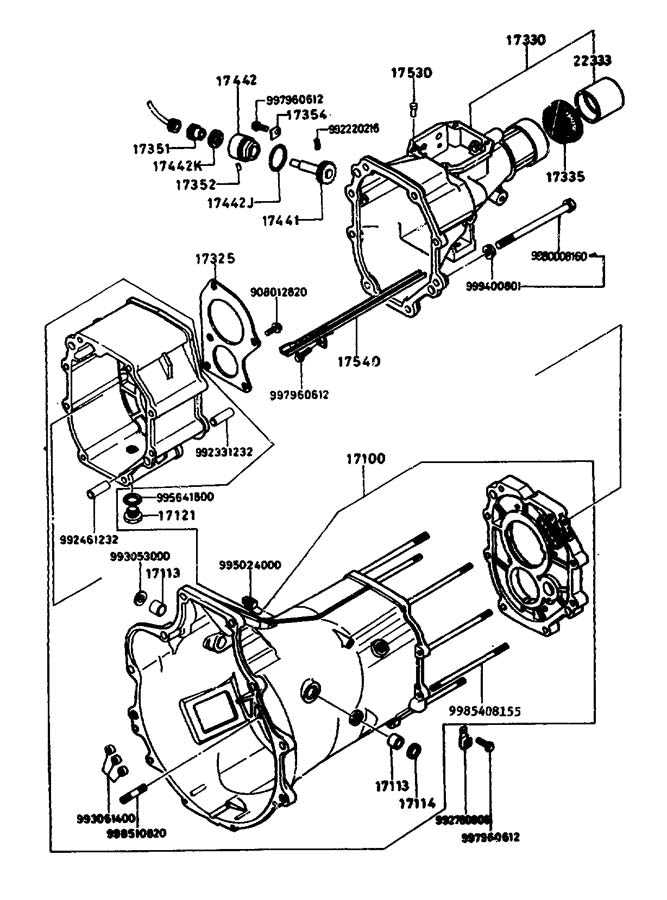

Supporting Elements in the System

- Synchronizers: Ensure smooth engagement of gears by matching their speed before they connect.

- Shifter Assembly: Provides the driver with the means to select the appropriate gear for the desired speed.

- Flywheel: Maintains rotational energy, ensuring smooth starts and stops of the vehicle.

Importance of Proper Maintenance for Gear Systems

Maintaining the critical components that regulate vehicle movement is essential for ensuring smooth performance and preventing costly repairs. Over time, wear and tear can affect the efficiency of these elements, leading to issues such as slipping gears or difficulty shifting. Regular care and attention to these systems help extend their lifespan and maintain the vehicle’s reliability on the road.

Proper upkeep includes regular inspections, lubrication, and replacing worn-out parts before they cause significant damage. Neglecting these tasks can result in poor vehicle performance, increased fuel consumption, and potential breakdowns. Ensuring the system remains in good condition not only improves driving comfort but also enhances safety and reduces the likelihood of expensive repairs in the future.