When it comes to maintaining high-performance cleaning machinery, a thorough understanding of its components is essential. These devices consist of various intricate elements that work in harmony to deliver optimal results. Having access to a clear breakdown of these components allows technicians and users alike to troubleshoot, repair, and maintain the system with confidence.

Knowing the key elements of the equipment can significantly improve both its lifespan and efficiency. From the motor to the nozzle, each part plays a vital role in ensuring smooth operation. By recognizing the functions and connections of these individual pieces, it’s easier to identify issues and make the necessary adjustments or replacements when needed.

For anyone working with such machinery, it’s crucial to familiarize themselves with the assembly and layout of the various components. Whether you’re a technician looking to repair a malfunction or simply aiming to improve the overall function, understanding how each part fits into the larger picture is key to effective maintenance.

Understanding Alkota Pressure Washer Components

Every cleaning system is made up of a variety of interconnected elements, each serving a specific purpose. These components work together to ensure the equipment operates efficiently and effectively. Understanding how each part contributes to the overall function is crucial for maintenance and troubleshooting. Whether you’re looking to replace a faulty part or optimize performance, having a clear understanding of the system’s makeup is key.

The heart of the machine typically includes a motor, pump, and hose, which drive the system’s operation. These core components are responsible for creating the force that powers the cleaning action. Additionally, the flow of water through various connectors and mechanisms needs to be regulated for smooth functionality. Knowing how each of these pieces works can help you quickly identify issues or prevent future malfunctions.

When dealing with maintenance or repairs, recognizing the role of each individual component is essential. For example, a clogged nozzle or a damaged pump can significantly impact performance. Understanding the connections between different elements allows for faster troubleshooting and ensures the longevity of the equipment. Proper care and timely replacement of worn-out parts can make a significant difference in the system’s effectiveness and lifespan.

Common Issues and Parts Replacements

Even the most durable cleaning systems can experience issues over time. Regular use can lead to wear and tear on certain components, affecting the overall performance of the equipment. Identifying common problems and knowing which elements need replacing can help restore functionality quickly, ensuring the system operates at its best.

Typical Failures and Symptoms

One of the most common issues is a reduction in cleaning power. This can be caused by worn-out seals, blocked hoses, or a malfunctioning motor. Another frequent problem is water leakage, which may occur due to damaged connectors or seals. Identifying these issues early can help prevent further damage and costly repairs.

Replacing Worn Components

When components begin to show signs of wear, it’s important to replace them promptly. Common replacements include hoses, seals, and nozzles. Each of these parts plays a crucial role in the system’s operation, and failure to replace them can lead to decreased efficiency or even complete breakdowns. Regular inspection and timely replacement can significantly extend the life of the machine.

How to Identify Alkota Washer Parts

Recognizing the various components of your cleaning system is an essential skill for proper maintenance and repair. Each part plays a specific role in the overall functionality, and identifying them correctly can help ensure you’re addressing the right issue when troubleshooting. Whether you’re dealing with performance issues or simply performing routine maintenance, knowing how to spot the key elements is crucial.

Start by familiarizing yourself with the basic structure of the machine. The most important components typically include the motor, water intake, pressure regulator, and various connectors. Take note of the labels or numbers found on individual parts, as these can often provide valuable information for identification. Additionally, understanding how each component is connected to others can help you quickly pinpoint which element is causing a problem.

Another helpful tool is the user manual or schematic, which can provide detailed images and descriptions of the components. If available, these resources are invaluable for identifying each part and understanding its function. By regularly inspecting the system and consulting available guides, you can ensure that each element remains in optimal condition.

Guide to Maintenance and Repairs

Proper upkeep of your cleaning system ensures long-term efficiency and reliability. Regular maintenance and timely repairs help avoid costly breakdowns and extend the equipment’s lifespan. This guide will walk you through the essential steps for maintaining and repairing your system to keep it in peak condition.

Routine Maintenance Tasks

Performing basic maintenance on a regular basis is crucial for keeping the system running smoothly. Here are some key tasks to include in your routine:

- Inspect hoses: Check for cracks or blockages and replace if necessary.

- Clean filters: Remove debris from water intake filters to ensure optimal flow.

- Lubricate moving parts: Apply lubricant to prevent friction and wear.

- Check seals: Examine seals for damage and replace them to avoid leaks.

Repairing Common Issues

If your equipment shows signs of malfunction, addressing the problem quickly can prevent further damage. Here are some common repairs to keep in mind:

- Replacing the motor: If the motor fails to start or runs intermittently, it may need to be replaced or repaired.

- Fixing water leaks: Inspect the connectors and seals for leaks and replace any damaged parts.

- Replacing nozzles: If the spray pattern is inconsistent, a damaged nozzle may need to be replaced.

By staying on top of both maintenance and repairs, you can keep your system functioning efficiently and avoid unexpected downtime.

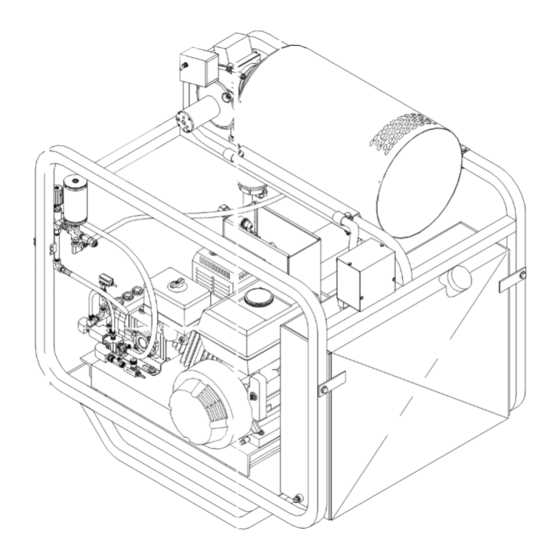

Exploring Alkota Pressure Washer Diagrams

Having a clear visual representation of your equipment’s internal components can significantly enhance your understanding of how everything works together. These illustrations not only show the layout of each element but also provide valuable insights into how different parts interact, helping you troubleshoot issues more efficiently. By studying these visual guides, users can gain a better grasp of the system’s design and functionality.

Detailed schematics are especially helpful when dealing with complex systems, as they allow you to quickly locate the source of any problem. These visuals break down each section, showing the connections between components and pinpointing areas that require attention. Whether you’re performing repairs or simply conducting routine maintenance, diagrams are an essential tool for ensuring accuracy and efficiency.

| Component | Function | Maintenance Tips |

|---|---|---|

| Motor | Powers the system | Lubricate and inspect for wear |

| Water Intake | Regulates water flow | Check for clogs and replace filters regularly |

| Hoses | Transfers water throughout | Inspect for damage and replace if cracked |

| Nozzle | Directs the water stream | Clean and replace when spray becomes uneven |

Using these resources, you can approach maintenance and repairs with greater confidence and precision. By referencing clear and accurate illustrations, you’ll be able to identify components, follow assembly instructions, and troubleshoot problems more effectively.