When dealing with any cleaning tool, knowing its internal mechanisms is essential for effective operation and maintenance. Proper understanding of the components allows users to maximize the longevity and performance of their machines. Whether you are using it for home maintenance or heavy-duty tasks, familiarizing yourself with the structure of the equipment can save time and money.

Every machine has a unique design, featuring several integral elements that work together to achieve optimal performance. By examining these key components, you can quickly identify potential issues and troubleshoot them without needing professional assistance. Regular checks and awareness of your equipment’s layout will help keep it running smoothly over time.

Regular maintenance becomes much easier when you understand how each part interacts with others. This knowledge is valuable not just for repairs but also for maximizing the efficiency of your tool. Recognizing the right parts and their functions can significantly improve the cleaning results you achieve.

Understanding Cleaning Equipment Components

Each cleaning tool consists of various elements that play a crucial role in its overall functionality. These components work together to ensure efficient operation and effective performance. Recognizing how these parts interact allows for better maintenance and quicker troubleshooting when issues arise.

The key parts of such a machine are designed to handle different tasks, from generating power to directing water flow. Some elements focus on power delivery, while others manage the flow of water or pressure regulation. A clear understanding of these components makes it easier to identify specific areas that may need attention during maintenance.

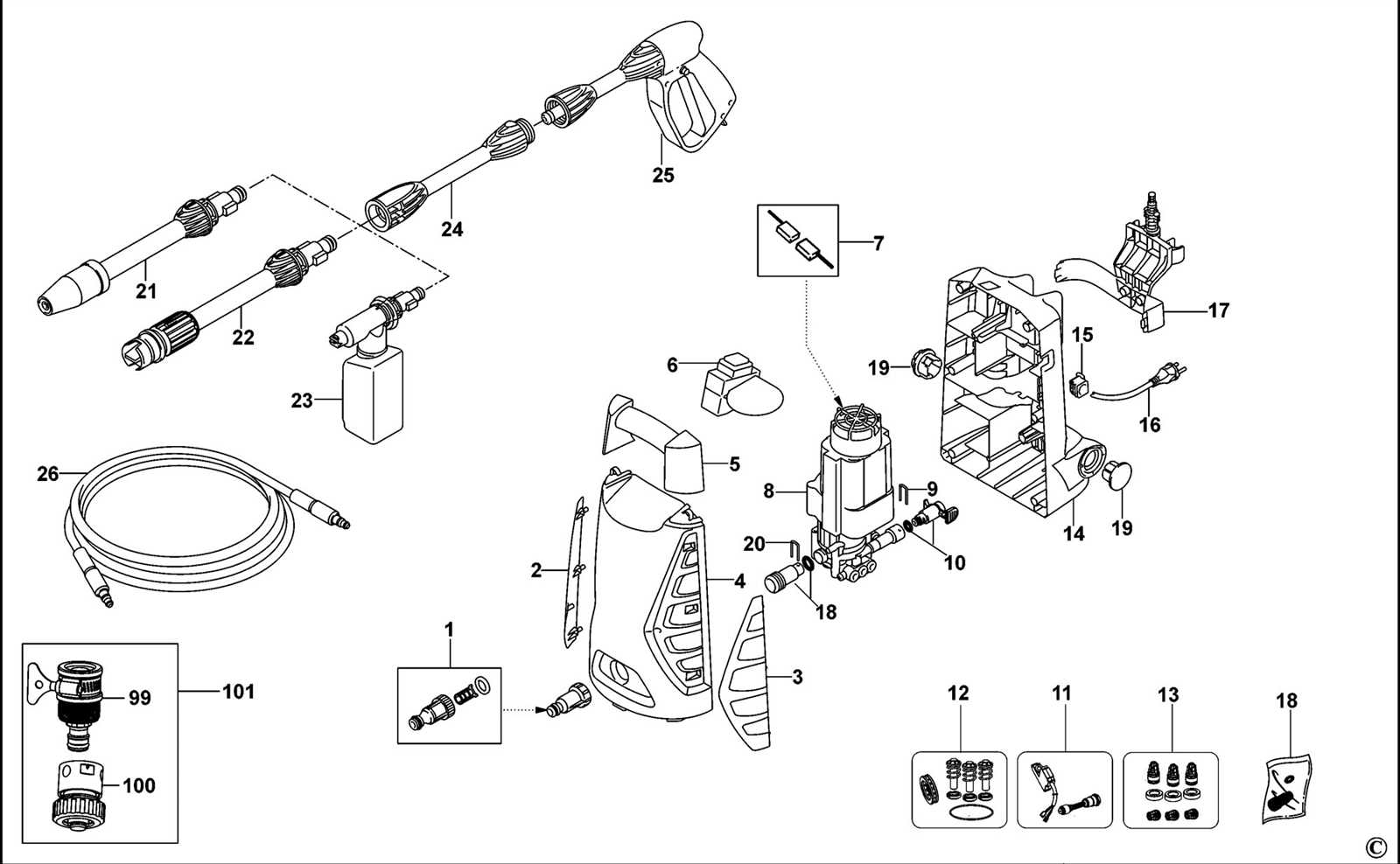

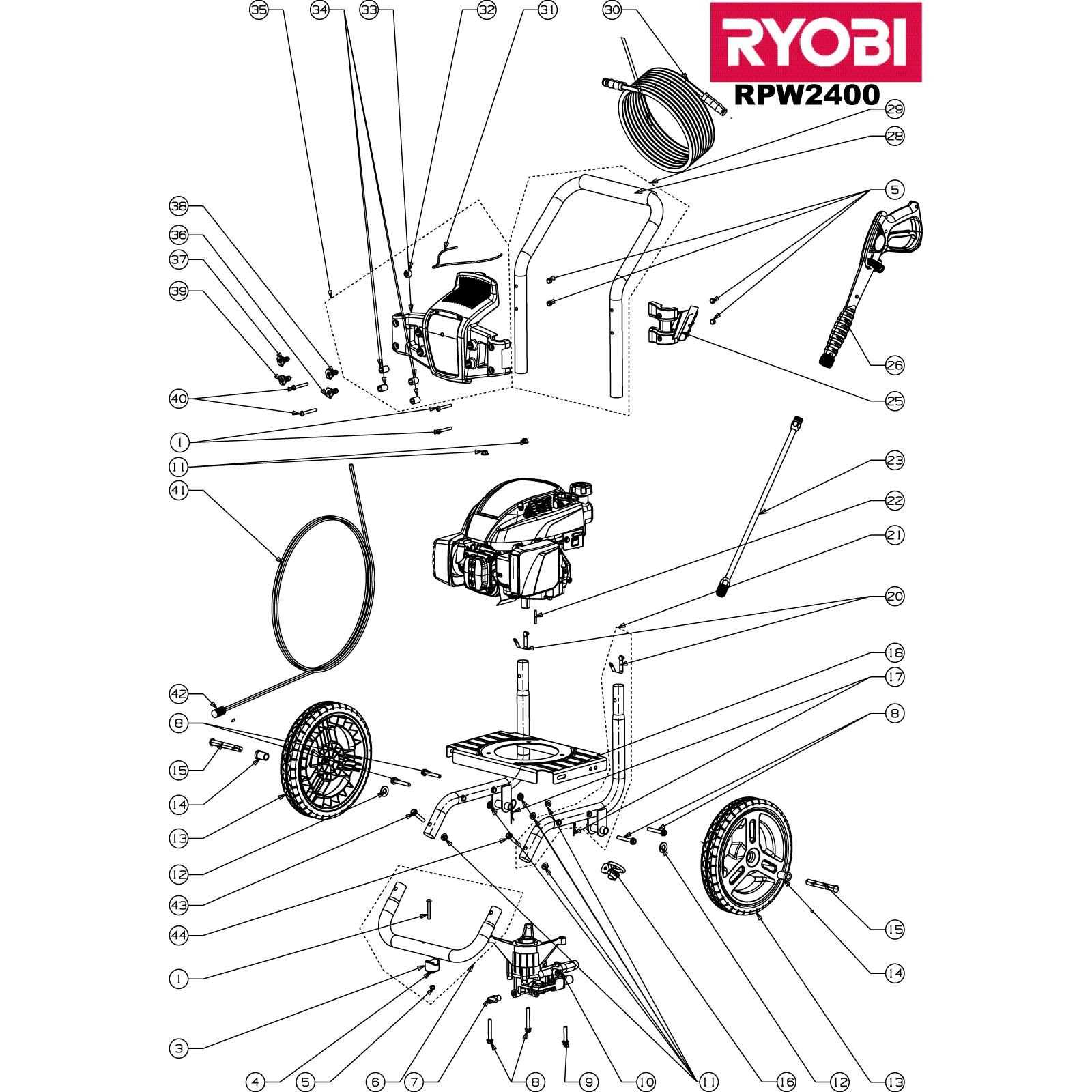

When familiarizing yourself with the tool’s structure, focus on elements such as the motor, pump, and nozzle system. Each one contributes significantly to the performance, and knowing their roles can prevent unnecessary repairs and enhance the efficiency of your equipment. By properly maintaining these components, you ensure that the entire system runs smoothly and effectively for a longer period of time.

How to Identify Cleaning Equipment Components

Knowing how to identify the individual elements of your cleaning tool is essential for proper operation and maintenance. Each part serves a specific function, and understanding these functions can help you quickly identify issues and make necessary repairs. By recognizing the main components and their characteristics, you can avoid unnecessary confusion and ensure that everything is in working order.

Inspecting External Features

The first step in identifying components is examining the external features of the machine. Pay attention to the frame, hoses, and any visible controls or switches. These external elements often provide the first clues about the type and role of different components. For instance, the hose connections indicate where the flow of water enters and exits, while the control knobs help regulate different functions.

Understanding Internal Mechanisms

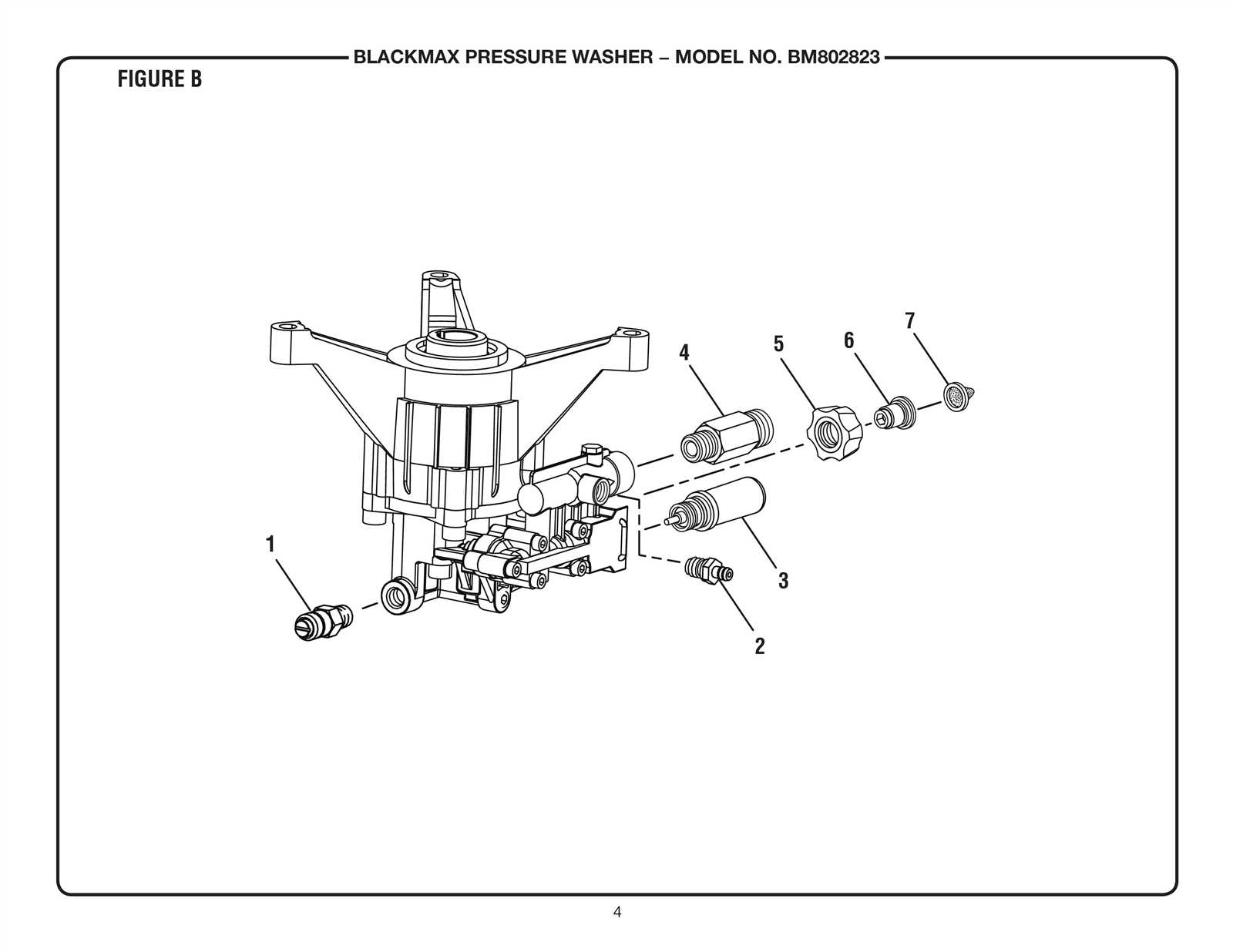

Once you are familiar with the external elements, it’s time to explore the internal components. The motor, pump, and various seals play significant roles in generating and controlling the power needed for effective cleaning. Look for labels, numbers, or manufacturer markings on each part that can help you identify its function and make the right decisions for repairs or upgrades.

Common Issues with Cleaning Equipment

Even the most reliable cleaning tools can experience problems over time. Understanding the most common issues can help users address them quickly and avoid major repairs. These problems typically arise from regular wear and tear or improper maintenance, and they often affect key components that impact the tool’s overall performance.

Loss of Power or Performance

A common issue with many machines is a noticeable decrease in performance. This can be caused by a variety of factors, such as clogged filters, worn-out seals, or a malfunctioning motor. When power is reduced, the cleaning efficiency also drops, making tasks take longer and requiring more effort to complete. Regular checks and maintenance can help prevent this issue from becoming more severe.

Leaks and Water Flow Problems

Another frequent issue involves leaks or disruptions in water flow. Leaks can occur due to damaged hoses, loose connections, or worn-out seals. This can lead to reduced pressure and wasted water, which lowers efficiency. Inspecting hoses, nozzles, and connectors periodically will help you spot potential leaks early and prevent operational problems.