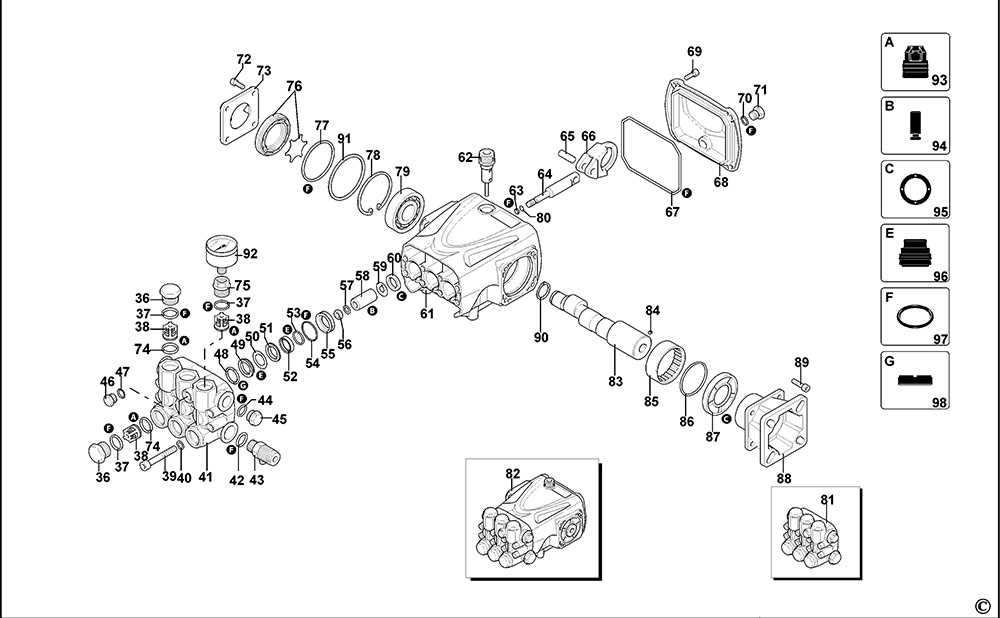

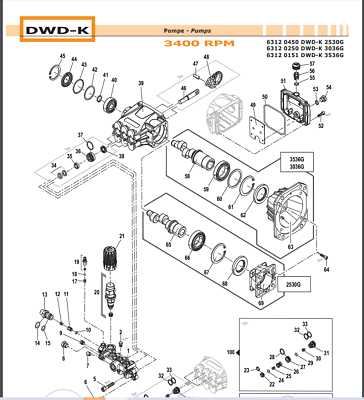

Maintaining the efficiency of your cleaning tools requires a clear understanding of their internal mechanisms. Each component plays a crucial role in ensuring optimal performance. Whether you are troubleshooting or performing regular maintenance, having a visual guide to the essential elements can make the process easier and more effective.

Familiarizing yourself with the individual pieces is the first step in understanding how they contribute to the overall functioning of your device. From the motor to the various connectors, each part is interconnected, and identifying where issues might arise can help you resolve problems swiftly.

Knowing how to assemble and disassemble your equipment can also assist in enhancing its lifespan. With a clear breakdown, you can easily replace worn-out pieces or clean them for continued use, ensuring the longevity of your tools and the quality of your work.

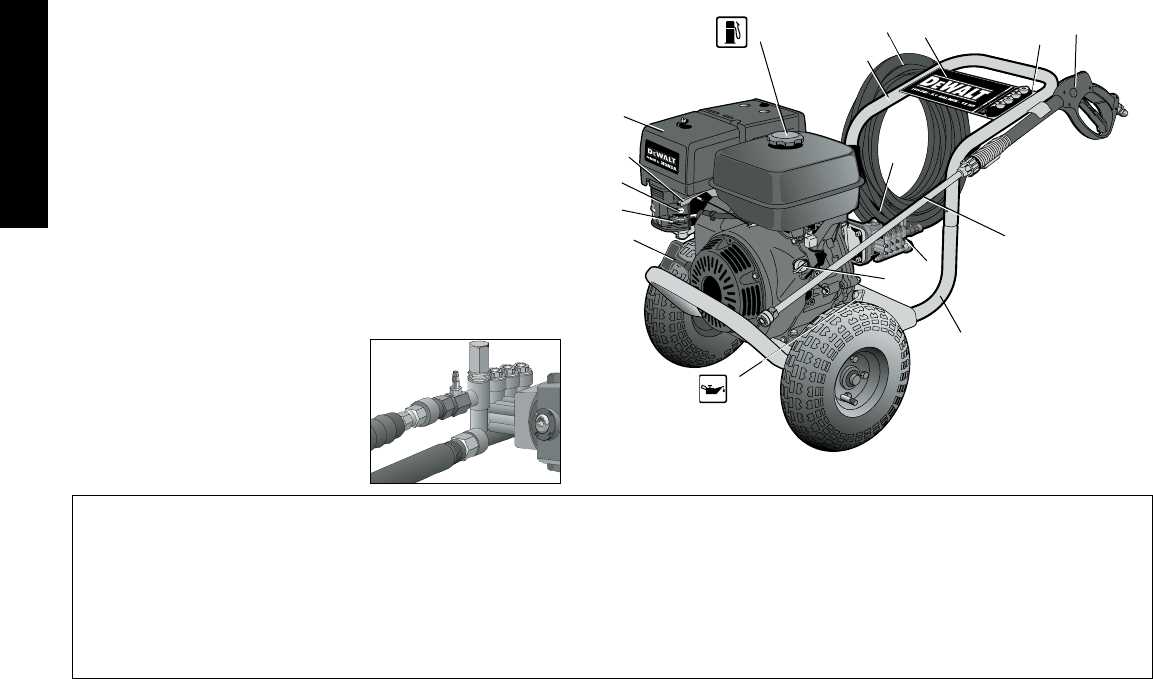

Understanding Dewalt Pressure Washer Components

Every cleaning device consists of a variety of interconnected elements, each playing a specific role in its overall performance. To ensure your equipment functions smoothly, it’s essential to familiarize yourself with the individual components. Recognizing how these parts interact helps you troubleshoot issues, perform maintenance, and optimize the machine’s efficiency.

The motor, for instance, serves as the heart of the system, generating the force necessary to drive the other components. Nearby, the intake valves, hoses, and connectors work together to deliver water, while nozzles and pumps adjust the flow rate to meet specific cleaning demands. Understanding these key pieces and their functions can empower you to make informed decisions when servicing or replacing them.

Additionally, regular inspection of these components allows you to spot wear and tear before it leads to more significant problems. Keeping each element in top condition is crucial for maintaining peak performance and extending the device’s lifespan. Whether you’re using the machine for heavy-duty tasks or everyday cleaning, a clear understanding of how it operates ensures that you get the most out of your investment.

How to Identify Pressure Washer Parts

Recognizing the individual components of your cleaning equipment is crucial for effective maintenance and troubleshooting. Knowing the function of each element helps you pinpoint potential issues and understand how to properly assemble and disassemble the device. Identifying these components is the first step toward extending the life of your equipment and ensuring optimal performance.

Familiarize Yourself with Key Components

Start by studying the major pieces such as the motor, hoses, and the water inlet. These are essential for the operation of the device. The motor, usually located at the back or center, powers the system, while the hoses direct the water flow to the nozzle. The pump, responsible for increasing water pressure, is also a central piece that you should be able to identify easily.

Examine Smaller Attachments and Accessories

Smaller elements like the spray gun, nozzles, and connectors should also be carefully examined. These attachments control the flow of water and the intensity of the spray. Each nozzle is designed for different tasks, so recognizing these and their purposes is important for selecting the right tool for the job. Proper identification of these accessories ensures you’re equipped for various cleaning challenges.

Understanding the function of each component can greatly improve your ability to troubleshoot problems and perform maintenance. When you’re familiar with the system, replacing a worn-out part or cleaning a clogged component becomes a straightforward task.

Common Issues with Dewalt Washer Parts

Even the best-maintained equipment can experience occasional malfunctions. Understanding the common problems that can arise with your device’s internal elements helps you act quickly to fix them before they affect performance. These issues can range from simple blockages to more complex mechanical failures that require replacement of specific components.

Clogs and Blockages

One of the most frequent issues is the accumulation of debris inside the system. Over time, dirt, mineral deposits, or even small objects can block the flow of water, reducing the efficiency of the machine. This problem is often seen in the hose, nozzles, or water intake. Regular cleaning and inspection of these areas can prevent this type of malfunction from occurring.

Wear and Tear on the Motor and Pump

The motor and pump are essential for generating the necessary force to operate the system. However, they are subject to wear and tear over time, especially if the equipment is used frequently or for heavy-duty tasks. Common issues include overheating, worn-out seals, or reduced power output. These problems can be addressed with routine maintenance or replacement of the affected parts to restore functionality.

Proactive maintenance is the key to preventing these issues from escalating into larger, more costly repairs. Regularly inspecting your machine and replacing parts as needed will help keep it running at peak performance for longer periods.