In every home appliance, there are crucial elements that work together to ensure smooth and efficient operation. These components form the core of the device and are essential for its performance and longevity. Understanding how these pieces interact with each other can significantly improve your ability to maintain and troubleshoot the unit.

Knowing the internal structure and the role of each component can save you time and effort in diagnosing any issues that may arise. From the main motor to the smaller supporting systems, each part plays a vital role in the overall functionality.

Proper knowledge of these systems can also help you avoid costly repairs, as you’ll be able to detect and fix minor issues before they escalate. This guide will walk you through the essential elements of the device, highlighting their functions and offering helpful maintenance tips.

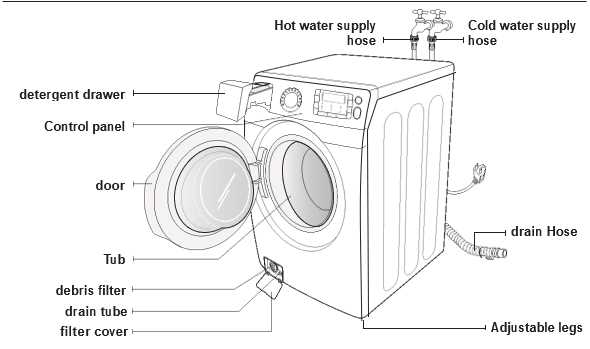

Understanding the Components of a Front Load Washer

Every appliance relies on several interconnected systems that work in harmony to provide efficient performance. These individual elements, although distinct, play an integral role in ensuring the unit operates smoothly. Familiarizing yourself with their functions and interactions is essential for both troubleshooting and proper maintenance.

Core Functional Units

The primary units within the device handle the most critical tasks, such as controlling the rotation, water flow, and power supply. Each system relies on specialized mechanisms that ensure the proper operation of the appliance, from the motor to the valve. Understanding the core elements allows users to recognize how they contribute to the overall functionality.

Supporting Mechanisms and Accessories

In addition to the main functional units, there are supporting components designed to optimize performance and provide added convenience. These include the sensor systems, pressure regulators, and drainage units. Each plays a vital role in ensuring efficient energy use, water conservation, and smooth operation over time.

Key Parts and Their Functions Explained

Each system within the appliance is made up of specific components that serve distinct roles. Understanding the purpose of these critical elements allows for better maintenance, quicker troubleshooting, and improved overall efficiency. These key units work together to provide the seamless experience users expect.

The motor is at the heart of the operation, driving the motion needed for rotation and agitation. Alongside it, water valves regulate the flow of liquid, ensuring the proper amount enters the system. These components are complemented by sensors that monitor everything from temperature to pressure, adjusting settings for optimal performance.

Other elements, such as the drainage system and suspension components, ensure that excess water is efficiently removed and the entire unit remains balanced during use. Together, these pieces create a functioning network that keeps the appliance running at its best, delivering consistent results over time.

Common Issues with Front Load Machine Parts

Like any complex appliance, certain components may experience wear and tear over time, leading to malfunctions. Recognizing these common issues can help you identify problems early, preventing costly repairs and ensuring long-term efficiency. Many of these issues are linked to particular systems within the unit.

One frequent problem is a failure in the water valve, which can cause irregular water flow or leaks. Another common issue is with the drum and motor assembly, where improper rotation or strange noises may indicate wear or damage. Additionally, the drainage system may become clogged, leading to inefficient water removal and poor performance.

Other potential problems include sensor malfunctions, which can affect temperature control or water levels, and imbalances in the suspension system, leading to excessive vibrations during operation. Being aware of these issues allows you to take preventive measures and address them before they impact the appliance’s performance.

How to Identify and Troubleshoot Problems

Proper identification of issues is the first step in troubleshooting any malfunctioning appliance. Whether it’s an odd noise, failure to start, or inconsistent performance, pinpointing the cause can often save you time and money. By following a systematic approach, you can address minor issues before they escalate into major problems.

Common Signs and Their Solutions

Many issues can be traced back to specific symptoms. The following table outlines common problems, their possible causes, and suggested troubleshooting steps:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Unit not starting | Power supply issue, faulty switch | Check power connection and switch settings |

| Excessive vibrations | Imbalanced load, suspension failure | Ensure load is evenly distributed, inspect suspension components |

| Water not draining | Clogged drainage system | Check drain hose and pump for blockages |

| Strange noises | Damaged motor or drum | Inspect motor and drum for signs of wear |

Step-by-Step Troubleshooting Process

To effectively address issues, follow these steps: Start by observing the symptoms closely and consulting the manual for initial guidance. Then, check for visible damage or blockages. If you’re unable to resolve the problem, it may be necessary to contact a professional for more in-depth diagnostics and repairs.

Maintenance Tips for Long-Lasting Performance

To ensure your appliance continues to perform at its best, regular maintenance is essential. Proper care not only extends the lifespan but also keeps it running efficiently, reducing the risk of costly repairs. Implementing a few simple steps can help maintain smooth operation and prevent future issues.

Regular Cleaning and Care

One of the most important maintenance tasks is keeping the internal and external components clean. This helps avoid buildup that can lead to malfunctioning. Here are some key cleaning tips:

- Clean the drum and door seals regularly to prevent mold and mildew buildup.

- Wipe down the exterior after each use to remove any dirt or detergent residue.

- Check the drainage system periodically to ensure there are no clogs that could affect water flow.

- Run a cleaning cycle with a descaling solution to keep internal components free of mineral buildup.

Periodic Inspections and Adjustments

In addition to cleaning, inspecting key systems can help catch potential problems early. Perform these checks to keep everything in optimal condition:

- Inspect hoses for wear and tear or signs of leaks.

- Check the balance of the appliance to ensure it isn’t vibrating excessively during operation.

- Examine belts and motors for any signs of damage or unusual wear.

- Test sensors and control systems to ensure they are responding properly.

Following these maintenance practices regularly will not only keep your appliance functioning smoothly but also reduce the likelihood of unexpected breakdowns, ensuring long-lasting performance.