When maintaining or repairing your outdoor cleaning tool, understanding its internal structure is crucial. Knowing how each element works together can help ensure efficient operation and prolong the life of the device. A thorough grasp of the system can save both time and money when it comes to troubleshooting or replacing worn-out parts.

Identifying each part in your equipment is key. By learning the layout and functions of the individual elements, you can spot potential issues early and handle them before they cause major disruptions. This knowledge also allows for easier navigation when sourcing replacement components.

Whether you’re performing routine maintenance or making repairs, having a clear visual reference can simplify the process. Understanding the connections between different components helps you approach any task with confidence and efficiency.

Understanding the Key Components of Your Cleaning Equipment

Every outdoor cleaning machine consists of several essential elements that work together to ensure its proper functioning. By understanding the role of each component, you can more effectively maintain and repair the equipment, leading to better performance and a longer lifespan. Identifying these key pieces helps in diagnosing issues and finding the correct solutions when problems arise.

The engine is typically the heart of the machine, powering the system and driving the necessary motions. Next, the pump is responsible for generating the pressure needed to perform cleaning tasks, while hoses carry the water or cleaning solution throughout the system. Additionally, nozzles and spray tips control the direction and intensity of the flow, making them crucial for efficient operation.

Each component’s location and function are critical to understand for maintenance and troubleshooting. Knowing how the parts interact with each other will enable you to assess and address any wear or malfunction swiftly. Having a clear overview of the equipment’s layout will also guide you in replacing specific parts, should the need arise, with ease and accuracy.

How to Read a Cleaning Equipment Layout

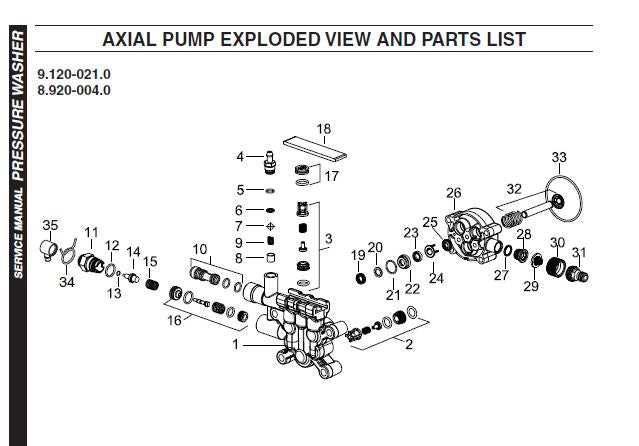

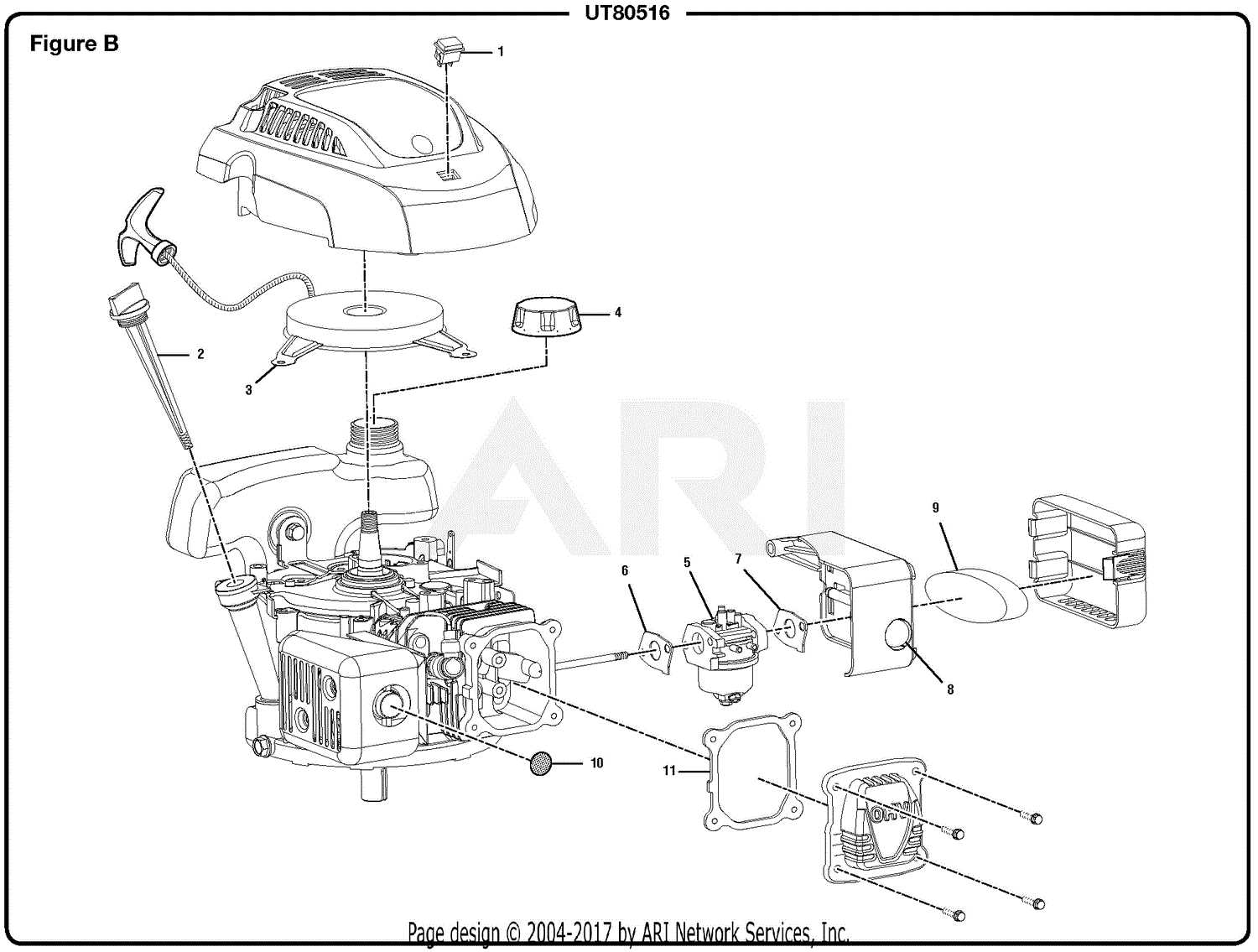

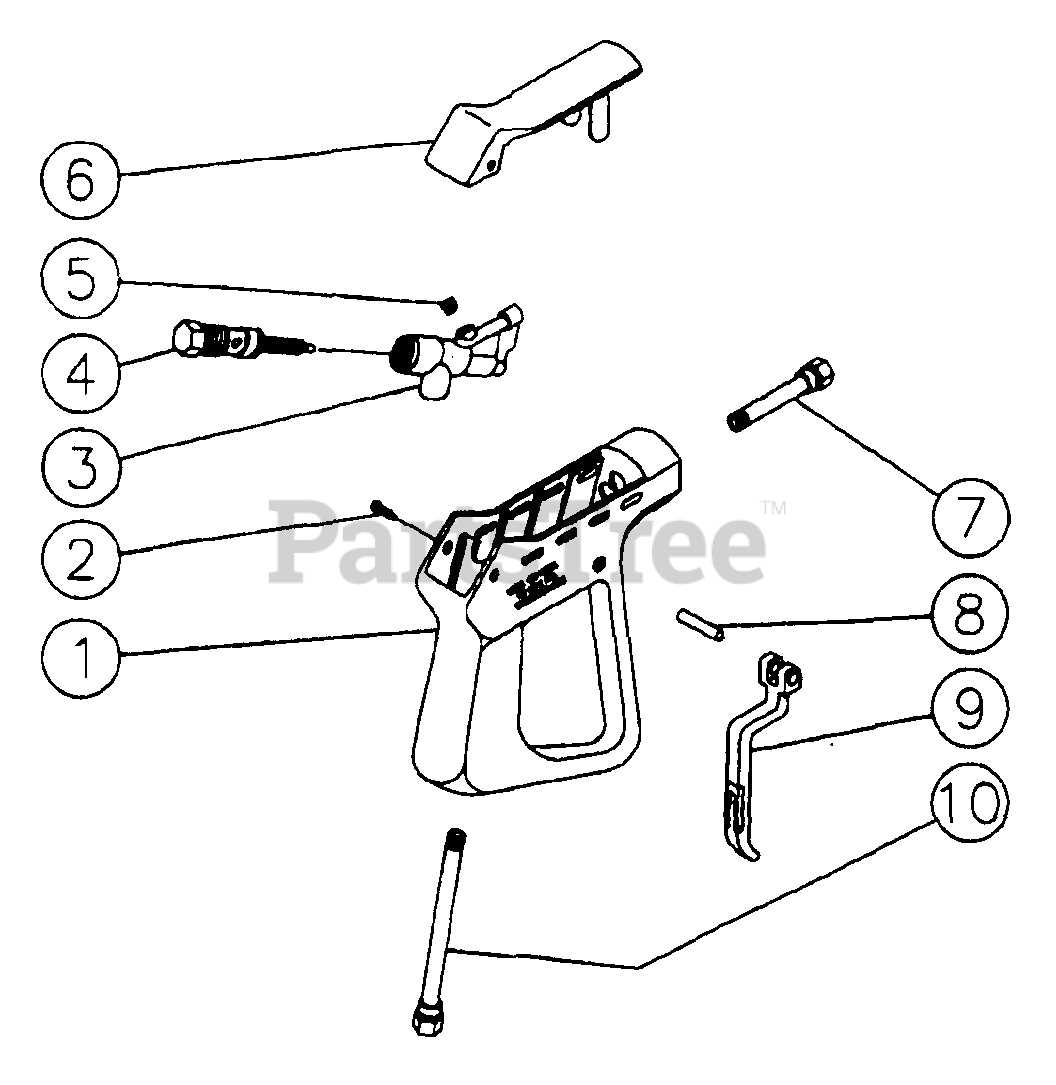

Reading a layout or schematic of your outdoor cleaning tool is an essential skill for understanding its internal components and how they function together. These visual guides provide detailed representations of each part, helping you to identify connections and troubleshoot effectively. Learning to interpret such diagrams will enable you to perform maintenance, repairs, and replacements with confidence.

Identify Each Component

Start by identifying the key components of the system. Typically, diagrams use specific symbols or shapes to represent different elements such as the engine, pump, hoses, and nozzles. Each part will be labeled clearly, allowing you to match the visual representation with the physical component in your machine.

Understand the Connections

Once you’ve identified the individual parts, the next step is to focus on the connections. Pay close attention to how elements are linked together through lines or arrows on the schematic. These connections represent the flow of water, pressure, or power between the components. Understanding these links helps in troubleshooting and ensures the proper setup during repairs or upgrades.

Essential Components for Effective Maintenance

To ensure the longevity and optimal performance of your outdoor cleaning equipment, it is vital to regularly maintain the key components. Each element plays a specific role, and understanding which parts require attention is crucial for preventing malfunctions and costly repairs. Regular inspection and timely replacement of worn parts will keep the machine running smoothly.

Engine and Pump

The engine and pump are the primary elements that drive the operation of the machine. The engine powers the system, while the pump generates the necessary flow and pressure for cleaning tasks. Regularly checking for wear, cleaning air filters, and ensuring proper lubrication will help keep these components functioning efficiently.

Nozzles and Hoses

Another important area to inspect includes the nozzles and hoses. These parts control the water or solution flow and distribute it effectively during cleaning. Over time, nozzles can become clogged or damaged, and hoses may develop leaks. Inspecting these components frequently ensures they perform optimally and can help prevent interruptions during use.