When dealing with household appliances, understanding their internal structure is essential for proper maintenance and repair. By knowing the key elements that make up your device, troubleshooting becomes easier, and you can efficiently fix issues yourself.

Each machine has various mechanisms that work together to ensure smooth operation. Recognizing these components and their functions can save both time and money, helping you make informed decisions when repairs are necessary.

In this guide, we will explore how to interpret the assembly layouts and identify common issues. With the right knowledge, you’ll be able to replace worn-out or faulty parts and restore functionality quickly, without the need for professional help.

Overview of Kenmore Washer 110 Parts

Every appliance consists of a range of elements that work together to ensure it functions effectively. Understanding the key components and how they interact allows users to recognize potential problems and make repairs when necessary. This section provides an overview of the critical components that contribute to the machine’s operation and durability.

Main Functional Components

The most important sections of the machine include the motor, water pump, and drive system. These parts handle the core tasks, such as initiating movement, circulating water, and controlling the machine’s speed. Each of these plays a vital role in achieving efficient performance, and knowing how they function can help diagnose and resolve malfunctions quickly.

Supportive Elements

In addition to the main mechanisms, several other components support the overall operation. These include switches, seals, and sensors that ensure smooth operation. Proper maintenance of these smaller but essential parts can prevent breakdowns and extend the lifespan of the appliance.

Detailed Breakdown of Key Components

To fully understand the function and maintenance of an appliance, it’s important to explore the individual elements that play a role in its operation. This breakdown highlights the primary mechanisms that make the machine run smoothly, from the core functions to the supporting parts that ensure longevity and efficiency.

Primary Mechanisms

The central elements of the appliance include the motor, transmission, and control board. The motor provides the necessary power for motion, while the transmission ensures the correct speed and direction. The control board acts as the brain of the machine, coordinating all the actions based on user inputs and sensor data. Each of these elements is crucial for the device’s overall performance and should be regularly checked for wear or malfunction.

Supporting Components

Aside from the main functional units, other smaller parts such as the pump, belt, and water inlet valve play key roles in ensuring proper operation. The pump circulates water, the belt connects moving parts for synchronized motion, and the water valve controls the flow during the washing cycle. These parts, while less visible, are just as important in maintaining smooth operation.

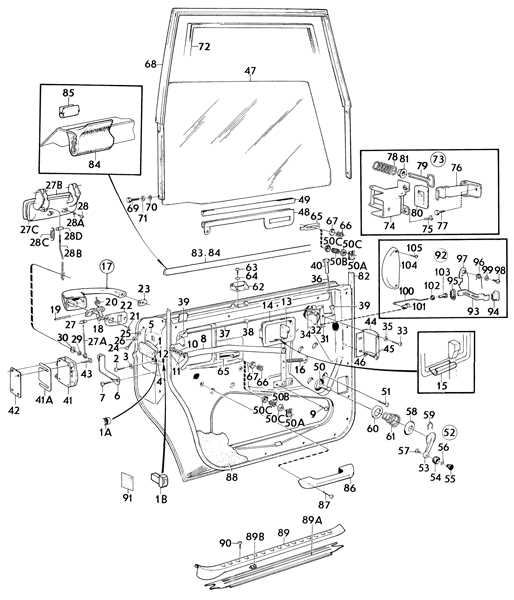

How to Read Kenmore Washer 110 Diagrams

Understanding the layout of your appliance through schematic representations can greatly aid in troubleshooting and repairs. These illustrations provide a detailed view of the internal components and their connections. Learning to interpret these visuals enables you to identify potential issues, locate parts, and follow repair steps with precision.

Identifying Key Symbols

Each diagram contains various symbols that represent different components, such as electrical connections, water flow systems, and mechanical parts. It is important to familiarize yourself with these icons to properly understand the information presented. Common symbols include:

- Circles: Indicate motors, pumps, and other rotating parts.

- Arrows: Show the direction of water flow or electrical current.

- Squares: Represent control units and switches.

Following Component Relationships

Once you recognize the symbols, focus on the connections between components. Diagrams typically show how parts are linked together, whether by wiring, hoses, or belts. This relationship mapping is crucial for understanding how a malfunction in one part might affect the entire system. By following the flow paths and connections, you can more easily pinpoint areas needing attention.

Understanding Part Layouts for Repairs

Properly understanding the layout of internal components is crucial when performing repairs. These layouts help visualize how different parts interact and fit together, making it easier to identify which components need to be replaced or adjusted. By analyzing these structures, you can approach fixes methodically and effectively.

The layout typically indicates the location of each mechanism and how it connects to others. This helps in locating the root cause of issues, whether it’s a malfunctioning motor, a worn-out belt, or a blocked valve. With a clear view of the layout, you can ensure that the right parts are targeted during repairs, reducing the risk of unnecessary disassembly.

Replacing Parts in Kenmore Washer 110

When components fail in an appliance, replacing them quickly can restore functionality and prevent further damage. Knowing how to properly remove and replace faulty mechanisms is key to successful repairs. This section explains the steps required to replace common components and get your device back in working order.

Steps to Safely Replace Components

Before starting any repair, ensure the appliance is unplugged and all water connections are disconnected. Begin by removing any outer panels or covers to access the faulty parts. Carefully examine the part for any signs of damage or wear. Once identified, gently detach it from its connections and install the new component, ensuring it is properly aligned and secured.

Common Replacements and Considerations

Common replacements include motors, belts, and valves. When replacing the motor, for example, it’s important to check that the new one is compatible with the model. Also, ensure that the power supply is safely reconnected after each replacement. Double-checking the functionality of the new part before reassembling the machine is always a wise step to avoid unnecessary rework.