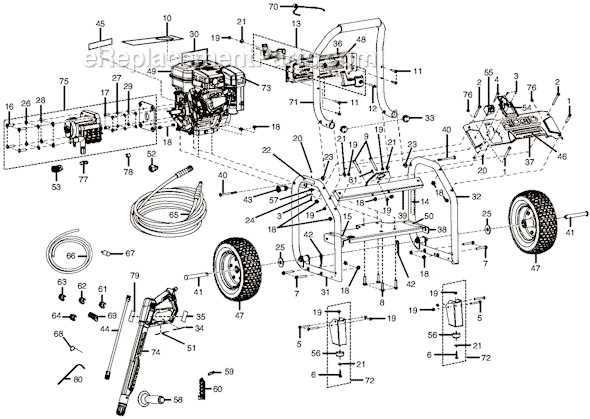

When dealing with high-performance cleaning equipment, knowing the essential elements that drive its function is crucial. Each component plays a significant role in ensuring efficiency and longevity. Having a clear understanding of how these components interact can prevent issues and simplify troubleshooting during maintenance tasks.

In this guide, we will explore the fundamental elements of such machines and how to identify them through visual aids. This knowledge will empower you to better manage repairs, upgrades, and overall care, ensuring optimal performance for extended periods.

Effective utilization of detailed visuals is a key aspect of simplifying maintenance processes. By understanding each part’s function, you can save time and money while maximizing the equipment’s operational lifespan.

Understanding Key Components of the Cleaning Equipment

Efficient operation of cleaning machines relies on a variety of interconnected elements. Each part serves a specific function, and understanding these roles helps ensure the machine performs at its best. A comprehensive knowledge of these components can help users maintain their equipment and quickly address any issues that arise.

Core Functions and Roles

The primary elements of such systems are designed to work together to produce the high power necessary for effective cleaning. From the motor to the nozzle, each piece of equipment plays a distinct role in generating pressure and directing water flow. A failure in one area can affect the overall performance, which is why it’s important to recognize the purpose of each component.

Identifying and Troubleshooting Common Issues

Recognizing the signs of wear and tear or malfunction in individual components can save time and prevent costly repairs. A well-maintained machine performs consistently, and understanding each element’s function makes it easier to troubleshoot issues quickly. Whether it’s a motor failure, hose blockage, or valve malfunction, identifying the right part to inspect is crucial for efficient repairs.

Common Issues and Solutions for Components

Like any mechanical system, cleaning equipment is prone to wear and tear over time. While regular maintenance can prolong the lifespan of its components, issues may still arise. Being able to identify common problems and their solutions can save time, reduce downtime, and minimize repair costs.

Leaking Connections

One of the most common issues is water leakage from connections. This typically occurs when seals or gaskets become worn out. Replacing faulty seals is usually the simplest solution. Regular inspection of hose fittings and connections can help detect leaks before they cause damage to other components.

Motor Malfunctions

If the motor fails to start or loses power, it may be due to electrical issues or a clogged intake. Cleaning the intake and checking wiring connections can help resolve these problems. In some cases, the motor may require professional repair or replacement if damage is extensive.

How to Use the Components Layout Effectively

Understanding how to navigate and utilize a detailed layout of the machine’s components is crucial for effective maintenance and repair. A clear and well-organized visual guide can help you identify each piece and understand its function. Proper use of this tool can simplify troubleshooting and make it easier to locate the right component when performing repairs.

Step-by-Step Identification

The first step in using the layout is to identify each component clearly. Begin by familiarizing yourself with the overall layout, noting key sections and their relationship to the rest of the machine. Cross-reference the components with the user manual to understand their roles and how they interact with other parts.

Locating Malfunctions Quickly

Once you are familiar with the layout, pinpointing the source of any malfunction becomes easier. When an issue arises, refer to the diagram to locate the affected part. Understanding how each component fits into the system helps you quickly assess what needs attention, whether it’s a simple part replacement or a more complex repair.