Properly maintaining the internal systems of cleaning equipment is essential for ensuring longevity and optimal performance. Knowing the functions of each individual component helps troubleshoot issues and perform repairs with ease. Without a clear understanding, identifying problems or replacing faulty elements can become a complex task.

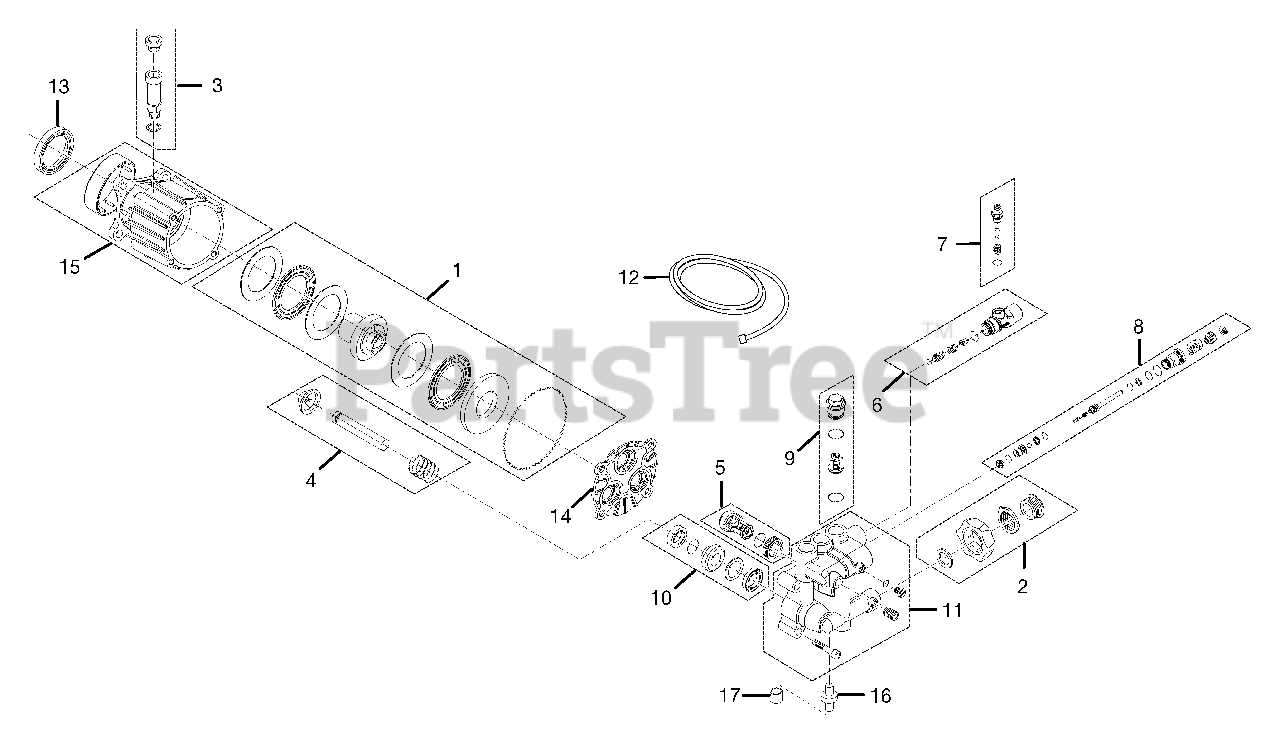

Detailed illustrations and schematics are valuable tools for both beginners and experienced technicians. They break down complex assemblies into digestible parts, providing a visual guide for identification and troubleshooting. These resources serve as a crucial reference when performing repairs or routine maintenance.

Whether you’re dealing with mechanical failure or routine upkeep, understanding the intricacies of the system will lead to more efficient repairs and a longer lifespan for the machine. This guide will provide clarity on how to interpret these visuals and make informed decisions on repairs or replacements.

Understanding Key Components of Cleaning Equipment

Every cleaning device consists of various essential elements that work together to ensure the equipment functions smoothly. Understanding how each component interacts and contributes to the overall performance is crucial for maintenance and repair. Whether you are troubleshooting an issue or performing regular upkeep, having a comprehensive knowledge of these parts can help you identify problems quickly and prevent costly repairs.

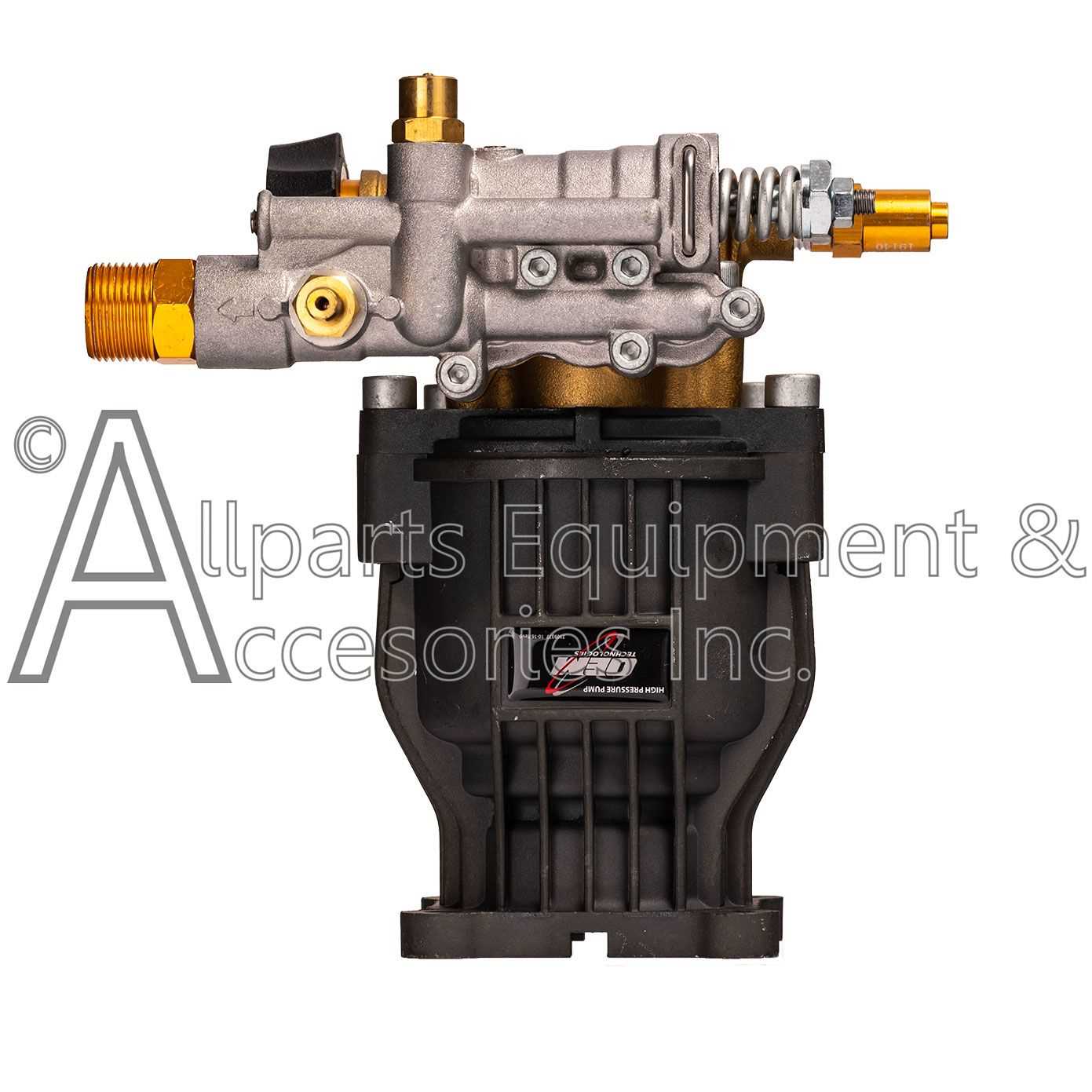

Essential Internal Mechanisms

The internal mechanisms of any machine play a central role in its operation. These systems, often comprised of gears, valves, and seals, manage the flow of energy and fluids through the device. Understanding their arrangement and function allows for more precise diagnostics and better decision-making when it comes to repairs or upgrades.

How Components Affect Efficiency

Each part influences the overall efficiency and output of the machine. A small malfunction in one element can lead to a decrease in performance, affecting both the speed and the quality of cleaning results. Knowing how each piece contributes to the efficiency of the system can help users prioritize maintenance tasks and avoid unnecessary downtime.

How to Identify Pump Components in Schematics

Recognizing different elements of a mechanical system in visual schematics is an important skill for anyone involved in maintenance or repair. These illustrations break down complex assemblies into individual sections, each labeled for easy identification. Understanding how to read these guides can streamline the process of troubleshooting and fixing issues.

Start by familiarizing yourself with the layout of the illustration. The components are typically arranged in a way that shows how they interact with each other. Often, each section is represented with a number or label, which corresponds to a detailed list or a key that defines each part’s role in the system. Understanding this numbering system is the first step in identifying and addressing issues.

Pay attention to the shape and placement of each element in the visual. While the shapes may vary depending on the specific machinery, most schematics use standardized symbols for common parts. By recognizing these symbols and their typical placements, you can more easily identify where issues may arise and pinpoint which components require attention.

Common Issues with Cleaning Equipment Systems

Many mechanical systems can experience malfunctions that affect their overall performance. Recognizing and addressing these issues early on can help maintain efficiency and prevent costly repairs. Most problems arise from wear and tear, improper maintenance, or the accumulation of debris, but understanding the common issues can greatly assist in resolving them.

One frequent issue is reduced output, which can occur when internal mechanisms become clogged or damaged. Obstructions such as dirt, debris, or damaged seals can cause the machine to underperform, resulting in lower efficiency and a longer cleaning time. Regular inspection and cleaning of the system are crucial to prevent these issues.

Another common problem is leaks, which can develop over time as parts age or seals wear out. These leaks can lead to a decrease in the effectiveness of the system and might cause damage to surrounding components. Identifying the source of leaks early and replacing faulty parts can help prevent more significant damage in the future.