When it comes to maintaining outdoor machinery, having a clear understanding of its individual elements is essential. Identifying and replacing worn-out components ensures that your tool operates at its full potential, saving both time and money on repairs.

Knowing how each piece fits together can be a game changer when diagnosing issues. With the right guide, users can easily find specific details about every section of the system, making maintenance tasks more straightforward.

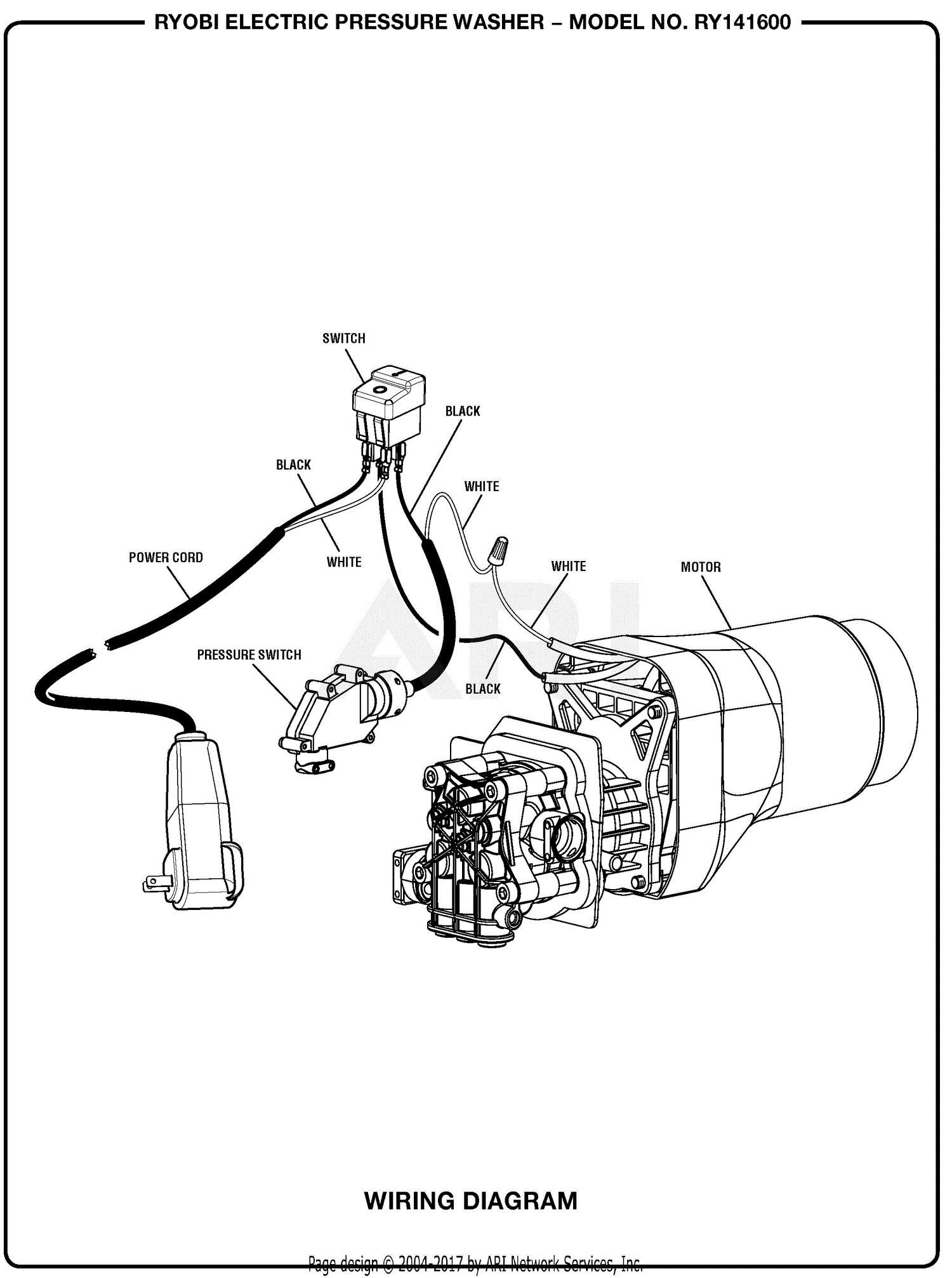

By using a detailed illustration of the system’s layout, anyone can quickly identify what needs attention. This is crucial for anyone who wants to keep their equipment running smoothly for years to come.

Understanding the Equipment’s Components

Knowing the individual components of your outdoor tool is essential for effective operation and maintenance. Each part plays a specific role, and understanding these roles helps users make informed decisions when it comes to upkeep, troubleshooting, and repairs.

By becoming familiar with how each element works together, you can identify issues more quickly and take appropriate action. It’s important to recognize which parts are most likely to wear out over time and which need periodic inspection to ensure proper functionality.

Key Elements of the System

The primary elements that make up the system include the motor, hoses, and other mechanisms responsible for transferring energy. Each component needs to be carefully examined for signs of wear, damage, or clogs that could disrupt performance. Regular checks are essential to avoid costly repairs and maintain peak efficiency.

How Components Interact

Understanding how the different components work together can make a significant difference when it comes to troubleshooting. For example, the energy flow between the motor, hoses, and other parts should be seamless to maintain high performance. Any disruption in this flow can lead to a drop in effectiveness, and knowing where to look will help you address the issue more efficiently.

Common Issues and Replacement Components

When using any outdoor machinery, certain problems tend to arise more frequently due to regular wear and tear. Identifying these issues early on can prevent further damage and keep the equipment running smoothly. Knowing which parts are most vulnerable helps in planning timely replacements to avoid major breakdowns.

From clogged filters to damaged seals, understanding the common failure points allows users to address the issues before they impact performance. Keeping track of these areas will ensure the longevity and efficiency of your tool.

Frequent Problems

One of the most common issues with outdoor equipment involves blockages in the system. This can happen when debris or buildup restricts the flow of air or liquid, reducing performance. Additionally, seals and gaskets are prone to wear and can lead to leaks, requiring attention to maintain optimal function.

When to Replace Components

Knowing when to replace a component is crucial to maintaining the tool’s efficiency. If a part shows signs of damage, such as cracks or severe wear, it should be replaced immediately. Regular inspections will help spot these issues early and ensure smooth operation throughout the tool’s lifespan.

How to Use the Components Layout Effectively

Utilizing a visual guide of your tool’s components can greatly simplify maintenance and repairs. By clearly showing how each element fits into the overall system, it allows you to quickly locate areas that need attention or replacement. Understanding how to navigate and interpret this guide ensures you are able to make accurate decisions during upkeep.

When using the visual layout, focus on identifying the main components first, and then break down the smaller parts that connect to them. This will help you avoid confusion and reduce the risk of overlooking essential parts during inspections.

Moreover, refer to the guide when replacing worn components to ensure you select the correct replacements. A proper understanding of the layout also helps you visualize the disassembly process, making reassembly faster and more efficient.