Maintaining a high-efficiency cleaning device requires understanding the key elements that ensure smooth operation. By familiarizing yourself with the individual components, you can troubleshoot issues and perform necessary repairs with ease. A thorough knowledge of these elements helps to extend the lifespan of the machine and optimize its functionality.

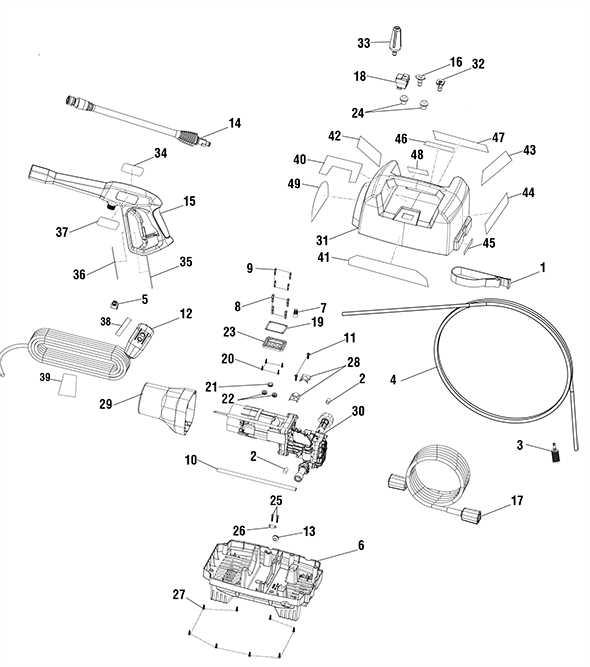

Regular inspection and maintenance of these elements are crucial for preventing common malfunctions. Having a visual representation of the system’s structure aids in recognizing parts that may need attention, such as wear and tear or damaged connections.

Whether you are a DIY enthusiast or a professional, this guide will provide the necessary insights to properly care for your cleaning equipment. A clear understanding of each component’s role will empower you to perform efficient repairs and replacements when needed.

Understanding High-Pressure Cleaning System Components

Every high-efficiency cleaning machine is made up of several essential elements that work together to produce optimal results. These components, each playing a specific role, contribute to the overall performance and durability of the system. Understanding how these parts function is key to effective operation and long-term maintenance.

The heart of the machine is the motor, which powers the system, while the pump regulates the water flow and pressure. Other important elements, such as hoses, nozzles, and connectors, ensure a seamless experience during use. Recognizing the role each component plays can help in diagnosing issues and performing repairs when needed.

By familiarizing yourself with these components, you can identify potential problems early on and address them before they affect the performance of your equipment. Proper maintenance and care of each part ensure that the system remains efficient and reliable for years to come.

Identifying Key Parts for Efficient Repairs

When it comes to fixing a high-efficiency cleaning system, understanding which components need attention is crucial. Being able to identify the main elements that contribute to the operation of the device allows for quick troubleshooting and ensures the right part is replaced or repaired when issues arise.

Critical components such as the motor, pump, and connectors are vital to maintaining the performance of the equipment. If any of these elements become worn or damaged, the overall efficiency can suffer. Identifying these parts early can save both time and money in repairs, as it prevents more serious problems from developing.

Having a visual reference or clear understanding of where each component is located and how it functions will make repairs faster and more efficient. This knowledge also helps in properly assembling and disassembling parts, ensuring the machine operates at its best after any maintenance work is done.

Step-by-Step Guide to Pressure Washer Maintenance

Proper upkeep of your high-performance cleaning equipment is essential to ensure its longevity and optimal functionality. By following a systematic maintenance routine, you can prevent common issues and enhance the overall efficiency of your system. Regular care minimizes the need for major repairs and extends the lifespan of the device.

Start with basic cleaning by removing any dirt or debris that may have accumulated on the exterior of the system. Inspect the hose, nozzle, and connections for any blockages or signs of wear. Regularly checking for leaks and ensuring all connections are tight helps maintain consistent performance.

Next, check the internal components, such as the motor and pump. These parts require occasional lubrication to function smoothly. Make sure the system is free from any buildup that could affect its operation. Following these steps on a routine basis will ensure your equipment remains in excellent working condition.