Every device designed for household chores consists of several critical elements, each performing a specific function. These components work together to ensure smooth and efficient operation. Understanding how these parts fit and interact is essential for proper maintenance and troubleshooting.

Knowing the layout of these internal systems allows users to easily identify potential issues and take necessary actions to fix them. Recognizing the key elements can help prevent unnecessary repairs and ensure the longevity of the equipment.

By familiarizing yourself with these fundamental structures, you can gain a deeper insight into the inner workings of your appliance. This knowledge empowers you to make informed decisions, whether for routine maintenance or when addressing a malfunction.

Understanding the Appliance Layout

Each household device designed for cleaning tasks consists of various crucial elements, all working together to deliver effective performance. These components, when arranged in a specific order, ensure the proper functioning of the appliance. Gaining knowledge of how these elements are organized and interact with each other allows for more efficient troubleshooting and maintenance.

Familiarity with the general structure of the internal components helps identify any issues that may arise, making it easier to address them promptly. Understanding the connections between these essential elements can save time and effort when repairs are necessary.

When you grasp the overall setup, you’ll be able to maintain the equipment more effectively and minimize downtime caused by technical problems. Recognizing each part’s role in the system allows for a smoother experience, whether you’re performing regular upkeep or fixing a malfunction.

Common Issues and Their Solutions

Devices designed for home use often experience certain problems due to wear, improper use, or other external factors. Identifying these common issues early on can prevent further damage and ensure the longevity of the appliance. Understanding the typical malfunctions and knowing the right solutions is key to maintaining its optimal performance.

For instance, a frequent issue is irregular or non-functioning cycles, which can be caused by faulty connections or issues with the motor system. A thorough inspection can often resolve these by fixing electrical connections or replacing worn-out parts.

Another common problem is unusual noises during operation, which may indicate a misalignment or obstruction within the moving elements. Addressing this early, by carefully checking the internal structure and components, can prevent more severe damage to the system.

Regular maintenance and early identification of these issues can significantly reduce repair costs and improve the efficiency of the equipment. Taking proactive steps to understand and fix common concerns will help keep the device running smoothly for years to come.

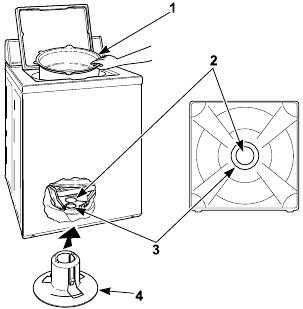

How to Read the Component Layout

Understanding how to interpret the internal layout of a device is essential for effective troubleshooting and repairs. A well-organized layout typically includes clear representations of each element, making it easier to locate and address issues. Learning how to read and analyze these diagrams can greatly simplify maintenance tasks.

Each section of the layout will usually include labels or numbers that correspond to specific components, helping you identify their placement and function. This visual representation allows you to follow the flow of energy and movement through the system, providing insights into how each piece works together.

By carefully examining the layout, you can spot potential areas of concern, such as worn-out or damaged parts. This knowledge empowers you to make more informed decisions when performing repairs or maintenance, ensuring the device remains in top condition for longer.