Knowing the inner workings of your cleaning device is crucial for effective maintenance and repair. Understanding how each element functions helps ensure that your tool runs smoothly and efficiently over time.

In this section, we will explore the individual components that make up your cleaning machine. You will learn how to identify the parts, troubleshoot common problems, and understand their roles in the overall system.

Proper knowledge of the components enables you to address minor issues before they escalate, ensuring long-term performance and avoiding unnecessary expenses. Whether it’s a minor part replacement or a deeper mechanical issue, knowing what each piece does is essential for successful upkeep.

Understanding the Components of Your Cleaning Equipment

Each cleaning device is composed of several key elements that work together to deliver optimal performance. Knowing the function of each part helps to identify potential issues and ensures the machine operates efficiently. These components are designed to perform specific tasks, such as controlling water flow, generating pressure, and distributing the output to the nozzle.

Main Internal Components

The core of the system involves the motor and pump. The motor drives the pump, which builds up the necessary pressure for the water. These two elements form the heart of the machine, as they generate the force needed for effective cleaning.

Additional Supportive Elements

Other essential parts include hoses, nozzles, and safety valves. These elements help direct the flow and control the pressure, allowing you to adjust the output according to different cleaning needs. Regular maintenance and occasional replacement of these parts can prolong the life of the equipment.

How to Identify Key Components for Repairs

Recognizing which parts require attention is crucial for effective troubleshooting and repairs. Whether you’re dealing with a loss of performance or unusual behavior, pinpointing the malfunctioning elements can save both time and money. A systematic approach helps identify which components need replacement or further inspection.

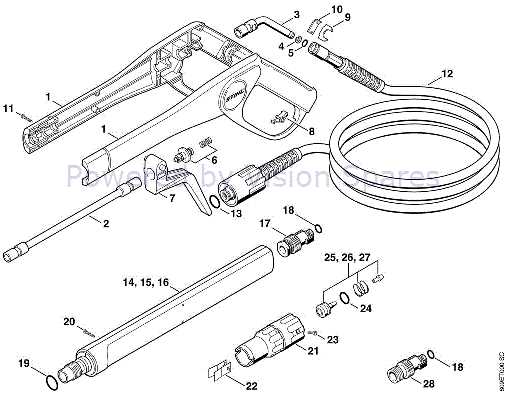

Start with External Elements

Begin by examining the outer elements such as the hose, connectors, and nozzles. These are often exposed to wear and tear from regular use, making them the first areas to check for damage or blockages. Cracks, leaks, or blockages in the hose can significantly impact functionality.

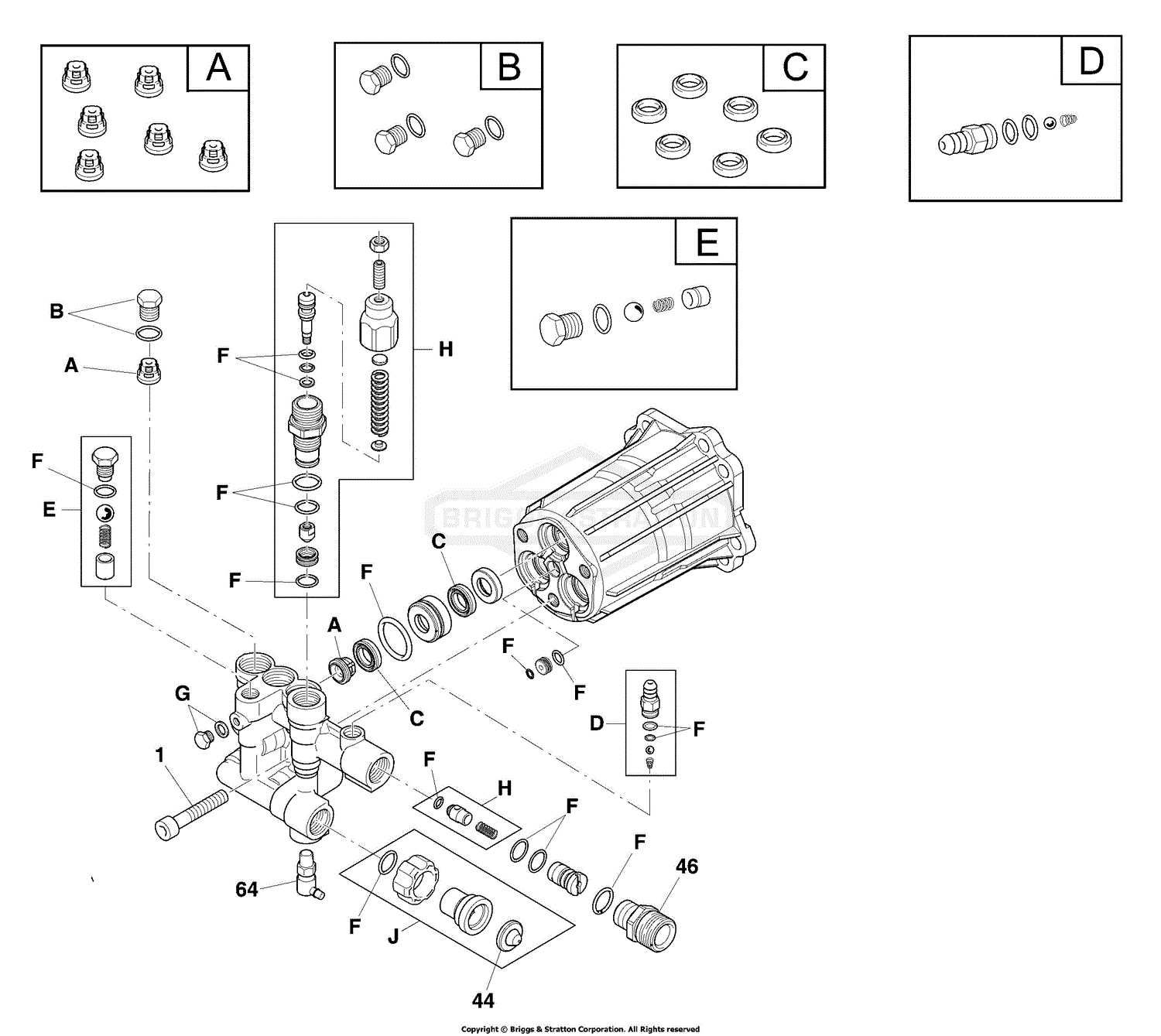

Check the Internal Mechanisms

Next, inspect the internal mechanisms, including the motor and pump. If the machine isn’t generating the expected pressure or making strange noises, the pump might be the source of the issue. Look for signs of leaks or excessive wear around moving parts.

Common Issues and Solutions for Cleaning Equipment

Like any mechanical device, cleaning tools can experience a range of issues that affect their performance. Recognizing common problems early allows for quick fixes, ensuring the machine continues to work efficiently. Below are some typical issues and their possible solutions to get your device back to peak condition.

Low Water Flow

If you’re noticing a decrease in water flow, check the hose for clogs or leaks. Ensure that all connections are secure and free of blockages. Sometimes, debris can accumulate in the nozzle or filter, reducing water flow. Cleaning these parts should restore proper functionality.

Inconsistent Pressure

Inconsistent pressure is often due to an issue with the pump or air in the system. Bleeding the air from the pump and inspecting the internal components for wear or damage can resolve this issue. If the pump is damaged, it may need to be replaced to restore full pressure.