Every modern household appliance consists of numerous intricate elements that work together to provide reliable performance. Knowing how these elements function and interact can help ensure longevity and effective operation. A well-maintained system is essential for achieving the best results with minimal effort.

Recognizing each crucial component is vital when troubleshooting or performing routine upkeep. Whether you’re repairing or simply familiarizing yourself with the unit, understanding its layout and function is a significant advantage. Proper knowledge helps detect potential issues early and avoid costly repairs.

Thorough familiarity with the key components also aids in quick and effective intervention during any malfunction. With the right guidance, you can identify which parts require attention and take appropriate action. This knowledge leads to greater efficiency and optimal performance in the long run.

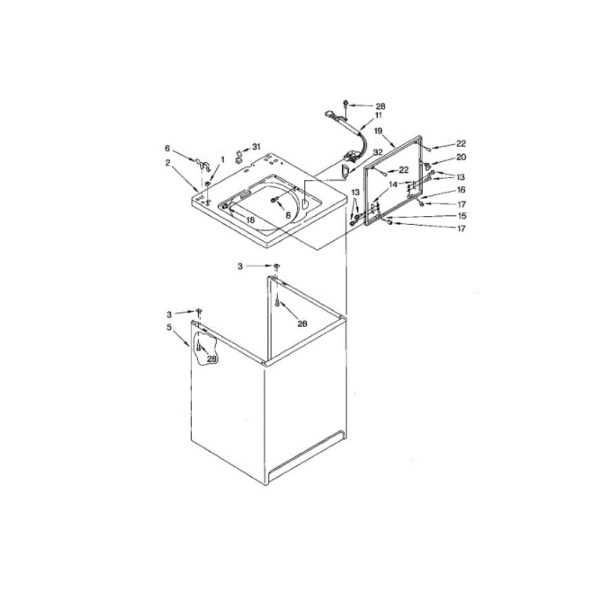

Essential Components of Whirlpool Top Loader

Each home appliance designed for cleaning tasks is made up of various key components that play distinct roles in ensuring its efficiency. These elements must work seamlessly together to achieve optimal performance, and understanding them is critical for anyone seeking to maintain or repair their equipment.

Core elements within the system are responsible for the appliance’s primary functions, such as water management, rotation, and control of various operations. Knowledge of these essential components allows users to better understand how the device achieves its tasks, ensuring proper usage and extending its lifespan.

In addition to functionality, recognizing how the internal parts are arranged and interact can also help in identifying issues early on. When any part is malfunctioning, it can impact the overall performance, making early detection and timely intervention key to preventing more significant problems.

Understanding the Internal Mechanisms

Inside every cleaning device lies a complex network of elements that work in harmony to achieve the desired results. Understanding how these mechanisms operate is key to both maintenance and troubleshooting. Each component has a specific role that contributes to the overall function of the machine, ensuring smooth performance during every cycle.

Water Flow and Management

The movement of water is a fundamental aspect of any appliance used for cleaning. It is carefully controlled through a series of valves, pumps, and sensors that regulate the flow, temperature, and drainage. This allows for efficient cleaning while conserving energy and water usage. Recognizing how these mechanisms work together can help diagnose issues related to improper water levels or drainage problems.

Motor and Agitation System

The motor plays a pivotal role in creating the necessary motion for agitation. It drives the drum’s rotation, allowing it to move clothing through the water. The interaction between the motor and agitation system is vital for effective cleaning. When this system fails, it can lead to poor washing performance. Understanding its function helps pinpoint any malfunction early.

How to Identify Key Washer Parts

Recognizing the crucial components of any cleaning device is essential for proper maintenance and troubleshooting. These elements are responsible for the machine’s functionality, and knowing where each one is located and what it does allows for more effective interventions when issues arise. Understanding the layout of the device ensures that users can address specific problems with confidence.

Begin by familiarizing yourself with the most prominent features that control water flow, movement, and electrical operations. These include valves, motors, belts, and sensors. By visually inspecting these components, you can spot any wear and tear or misalignments that could lead to performance issues.

Knowing how to identify each key element also allows for more precise repairs. Instead of relying on vague descriptions, users can directly pinpoint the malfunctioning part, which makes replacing or fixing it quicker and more efficient. Regular inspections help ensure everything remains in optimal working condition.

Helpful Tips for Maintenance and Repair

Regular upkeep and timely repairs are essential to prolonging the life of any appliance. By addressing minor issues before they escalate, you can ensure that your device continues to operate efficiently. Proper care involves both preventive measures and knowing how to resolve problems when they occur.

Routine cleaning is one of the most effective ways to keep things running smoothly. Ensure that areas exposed to water and detergent are cleaned regularly to prevent buildup that could affect performance. Removing lint, debris, and detergent residues helps maintain a clean environment for the internal components, reducing wear over time.

Another crucial step is to check for wear on moving parts. Belts, motors, and other mechanical elements can degrade over time, leading to inefficiency or breakdowns. Periodically inspecting these components and replacing worn parts can prevent more serious malfunctions, saving both time and money in the long run.

Common Issues and Part Replacement

Even the most reliable home devices can experience malfunctions over time. Knowing the common issues and how to address them is essential for maintaining smooth operation. Timely part replacement can resolve many of these issues, ensuring that your device continues to function at its best.

Frequent Problems

There are several issues that often arise with cleaning machines. Recognizing them early can save you from more serious complications. Common problems include:

- Failure to spin or drain properly

- Excessive noise or vibration

- Water leakage

- Irregular agitation or movement

When to Replace Components

Identifying when a part needs replacement can prevent damage to the entire system. If you notice any of the following signs, it’s time to check and possibly replace the affected part:

- Excessive noise: Indicates worn-out bearings or motor issues.

- Water leakage: May point to a damaged seal or hose.

- Failure to spin: Could be caused by a broken drive belt or malfunctioning motor.