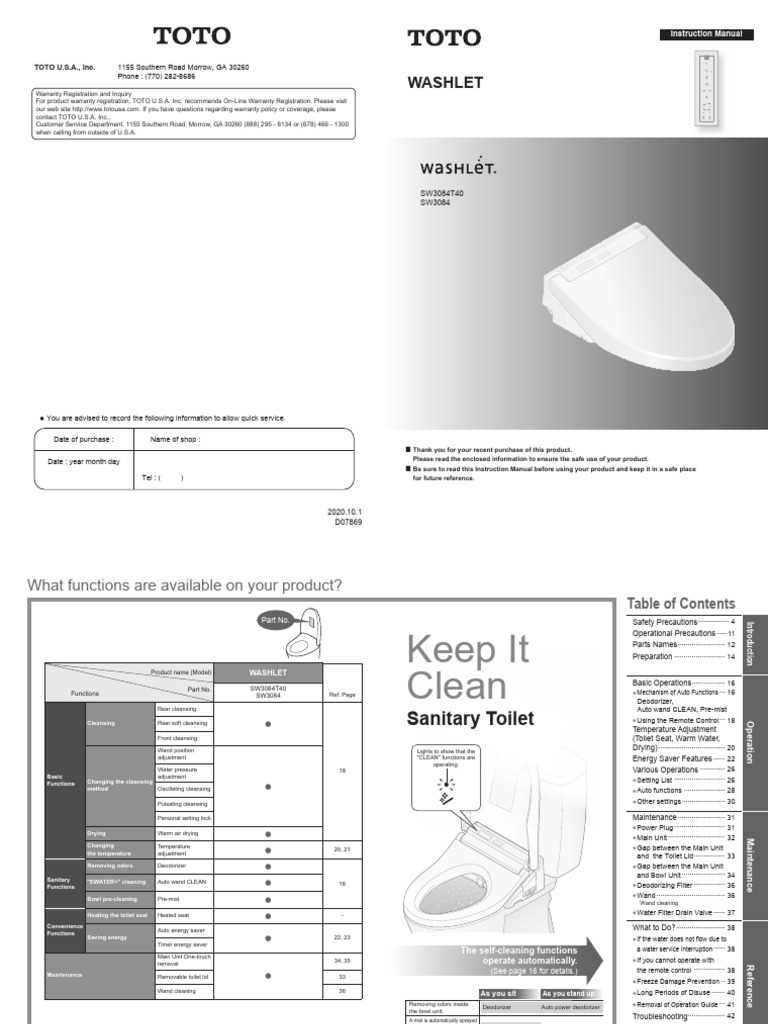

In modern bathroom technology, advanced seat systems combine comfort and functionality with carefully designed internal components. These systems often feature multiple elements that work together to enhance user experience, ease of maintenance, and longevity. A clear understanding of these components can help ensure proper usage and care, improving the overall functionality of the system.

Knowing the structure and individual components is essential for effective maintenance and repair. Each part plays a crucial role in providing a seamless experience, from the primary control mechanisms to the essential water management features. Whether you are a first-time user or experienced, gaining insight into the system’s layout can prevent misunderstandings and simplify troubleshooting.

Understanding how the system is constructed and how the various parts interact with each other is important for anyone aiming to optimize their experience. By familiarizing yourself with these essential elements, you can ensure longevity and reliability, keeping the system working efficiently over time.

Understanding Bathroom Seat System Components

Modern bathroom seat systems are built with advanced mechanisms that offer enhanced comfort and functionality. These systems consist of various integrated elements designed to provide a smooth user experience and efficient operation. By understanding the core components and their interaction, users can better appreciate the overall performance and maintain the system effectively.

Key Elements of the System

Each unit incorporates a series of essential components, such as water delivery systems, heating elements, and control panels. These parts are all designed to complement one another, ensuring that the seat system delivers optimal performance. Understanding the role of each component helps users troubleshoot issues and maintain the system more easily.

Importance of Regular Maintenance

Proper care of the individual components plays a vital role in ensuring the system remains in top condition. Regular checks and cleaning of crucial parts, such as the water nozzles and control mechanisms, are essential to prevent malfunctions. A strong grasp of the unit’s structure allows users to perform routine maintenance, avoiding potential repairs and extending the life of the system.

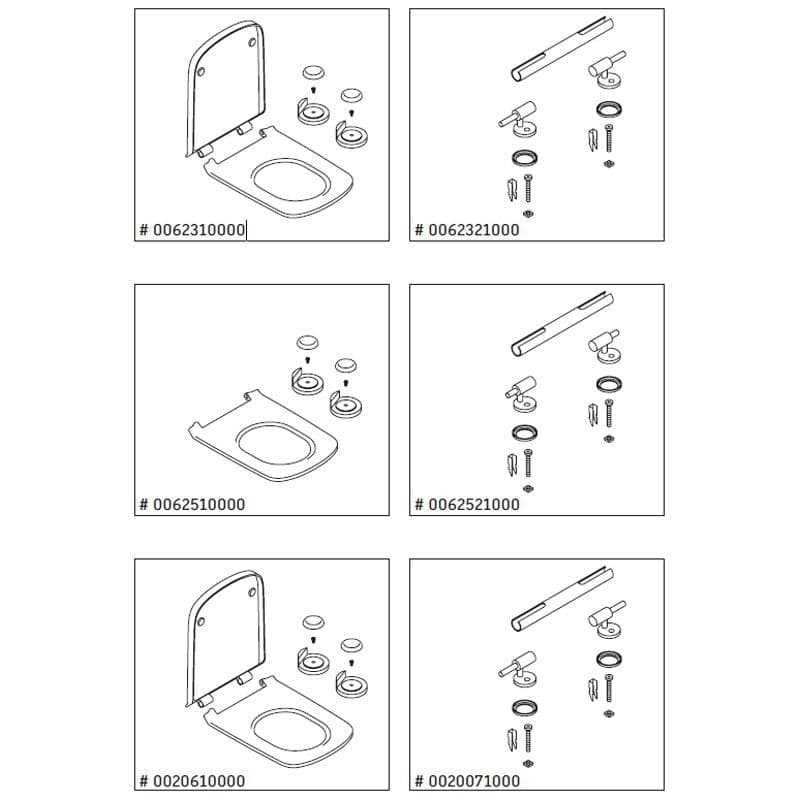

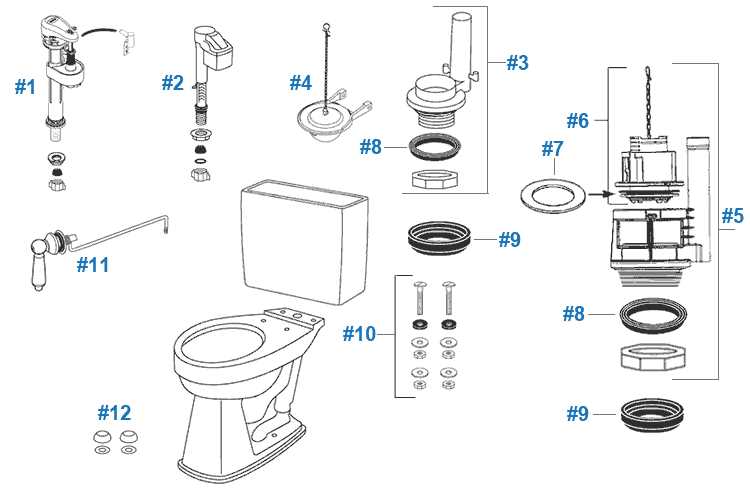

Identifying Key Parts of a Bathroom Seat System

In every advanced bathroom seat system, several critical components work in tandem to ensure comfort, hygiene, and functionality. These elements are designed to provide an efficient experience, from water management to control options, all contributing to the overall performance of the unit. Understanding these key components is essential for users aiming to make the most of their system.

The most important elements of such a system typically include the water dispensing unit, the heating mechanism, and the control interface. Each part has a specific function that enhances the user experience, whether through temperature regulation, cleaning options, or ease of use. Recognizing the role of each component is the first step toward maintaining or repairing the system when needed.

Assembly and Maintenance Tips for Bathroom Seat Systems

Proper assembly and regular maintenance are key to ensuring the longevity and efficiency of advanced bathroom seat systems. Each unit consists of multiple components that must be carefully installed and regularly maintained to function at their best. By following essential tips for both assembly and upkeep, users can prevent malfunctions and extend the lifespan of their system.

When assembling the system, it is crucial to follow manufacturer instructions precisely to avoid issues with connectivity or functionality. Ensuring that all connections are secure, such as the water supply and electrical components, will prevent leaks or power failures. For ongoing maintenance, routine cleaning of the nozzle, filter, and control interface is essential to maintain hygiene and performance. Regular inspections of the key components help identify wear and tear before they lead to more significant issues.