When maintaining outdoor equipment, it’s essential to have a clear understanding of the individual components that make up the system. Identifying each element helps ensure the proper functioning and longevity of the machine, as well as aids in troubleshooting any issues that may arise over time.

Maintenance and repair can be simplified when you know how each part contributes to the overall operation. Whether it’s a motor, a pump, or other key features, recognizing their roles can save you time and effort when addressing malfunctions or performing routine checks.

Familiarizing yourself with the layout and organization of the essential components allows for a smoother repair process, and it’s often the first step toward a successful fix. Knowing the parts by name and function ensures that you’re able to address problems quickly and efficiently.

Understanding Key Components of Outdoor Equipment

Proper functioning of outdoor machinery relies on the seamless operation of its various internal elements. Each component plays a vital role in ensuring smooth performance, from the engine to the flow system. Understanding how these pieces fit together and contribute to the overall function is crucial for effective maintenance and repairs.

From the motor that powers the system to the intricate network of hoses and valves, every part is designed to work in harmony. Recognizing the role of each element can help you quickly diagnose issues and prevent unnecessary damage to the equipment. A thorough understanding also aids in the safe and efficient replacement of faulty components.

Whether dealing with a malfunction or performing routine maintenance, familiarizing yourself with the layout and functions of essential components ensures you can manage the system more effectively. Knowledge of these parts allows for faster problem-solving and helps maintain the longevity of your machine.

How to Identify Components in the Layout

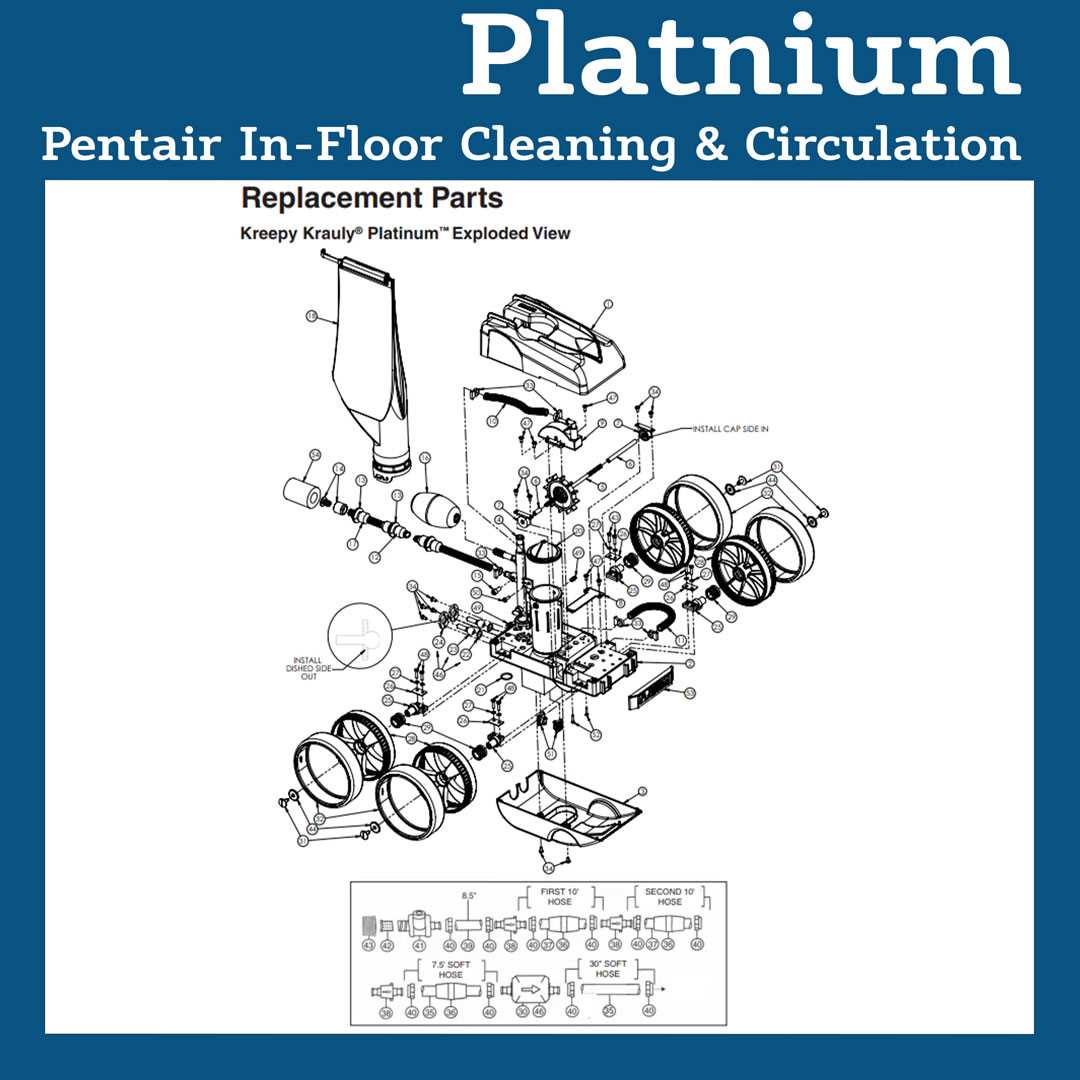

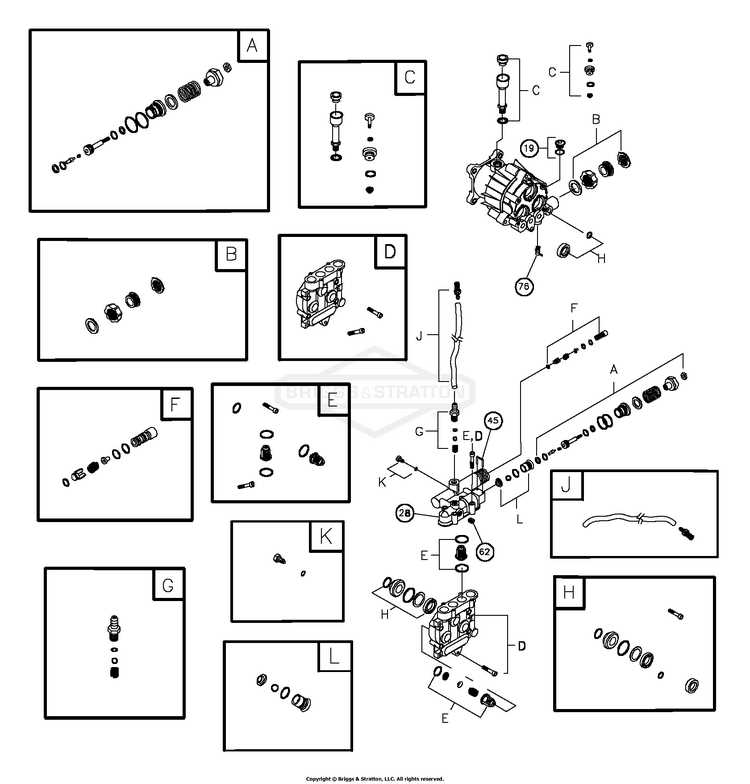

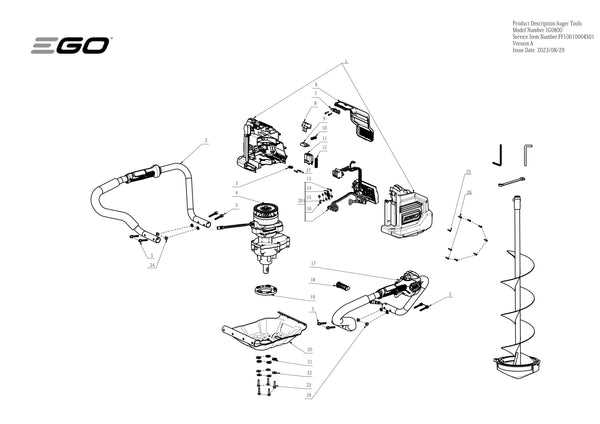

Understanding the layout of a machine is essential for quick identification of each individual element. To effectively navigate the various components, it’s important to know how to read and interpret the layout clearly. This guide will help you recognize each part and understand its function within the system.

Step-by-Step Identification

Start by examining the overall schematic to get a sense of how the parts are organized. Then, break it down into smaller sections to focus on specific areas of interest. Follow these steps to identify the key elements:

- Locate major components: Identify the engine, pump, and other core units. These are usually positioned centrally or in obvious places on the layout.

- Trace connecting elements: Look for hoses, valves, and pipes that link the major components together. Their placement often indicates their function.

- Identify secondary components: Smaller parts like filters, switches, and bolts will be shown in the diagram, usually in detail for ease of recognition.

Using the Diagram for Maintenance and Repair

The layout not only helps you identify each piece but also acts as a guide for disassembly or repair. Understanding how each part connects will make troubleshooting much easier. Follow the diagram closely during maintenance to ensure you’re working with the correct parts and replacing them accurately.

Common Issues and Replacement Components

Even with proper maintenance, outdoor equipment can experience common malfunctions due to wear and tear. Identifying these issues early allows for timely repairs and the replacement of any faulty elements, ensuring the machinery continues to function optimally. Understanding these common problems can help you avoid major breakdowns and extend the lifespan of the unit.

Frequent Problems and Their Causes

Several issues can arise during use, often stemming from component failure or misalignment. Some of the most common problems include:

- Loss of power: This may be caused by an issue with the motor or fuel system, leading to inefficient operation.

- Leaking fluid: Worn-out seals or damaged hoses may lead to fluid leaks, compromising the system’s functionality.

- Inconsistent performance: Clogged filters or dirty internal components can hinder the performance of the unit.

Replacement Solutions

Replacing faulty components is crucial for the continued performance of the equipment. Some common replacements include:

- Engines and motors: If the motor becomes damaged or inefficient, replacing it with a compatible unit restores full function.

- Seals and O-rings: Replacing these small but important components can prevent leaks and improve overall efficiency.

- Hoses and valves: Damaged hoses or malfunctioning valves should be replaced to avoid disruptions in the flow system.