Understanding how a lifting tool functions requires knowledge of its individual components and how they work together to provide efficient performance. The various elements within the mechanism each serve a unique purpose, contributing to the overall strength and reliability of the equipment. A deeper understanding of these features is essential for proper usage and maintenance.

Every lifting device is made up of several critical sections, each performing a vital role in lifting and supporting heavy loads. Familiarity with these elements allows for easier troubleshooting and ensures safe operation. Whether it’s the handle, release valve, or piston, knowing how these work in unison makes using the tool more effective.

Learning about the construction of such tools offers insights into their durability and helps with identifying potential issues before they compromise performance. Analyzing how each part interacts within the system is key to ensuring long-lasting functionality and reliability.

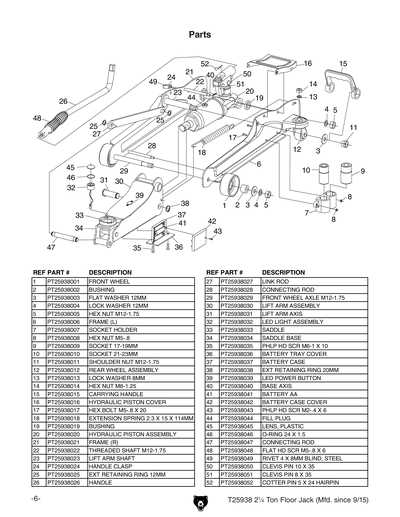

Understanding 2-Ton Floor Jack Components

To fully comprehend how a lifting device operates, it’s important to recognize the distinct elements that come together to ensure its functionality. Each section has been designed for a specific role, contributing to the overall effectiveness and reliability of the equipment. Familiarity with these components aids in proper maintenance and troubleshooting when needed.

The lifting mechanism is typically powered by a hydraulic system that includes essential components such as the pump, cylinder, and release valve. These parts work together to create the force required to elevate heavy objects while maintaining stability. Understanding how these elements interact provides a clearer picture of the tool’s performance under various conditions.

Additionally, other key sections such as the handle, wheel assembly, and saddle play important roles in ease of use and control. A sturdy handle ensures the user can manage the tool efficiently, while the wheels make it easy to maneuver the device into position. The saddle, on the other hand, ensures that the lifted object is held securely during the process.

Common Parts of a Hydraulic Floor Jack

The operation of a lifting tool relies on several fundamental components that ensure its hydraulic system works efficiently. These elements are designed to handle heavy loads while providing smooth and controlled lifting. Understanding each part is essential for both the functionality and maintenance of the equipment.

Hydraulic System Components

At the heart of the mechanism is the hydraulic system, which consists of a pump, cylinder, piston, and release valve. The pump generates pressure, while the cylinder and piston work in tandem to raise or lower the lifting platform. The release valve controls the descent, ensuring that the load is lowered gradually and safely. Together, these components enable precise lifting and stability during use.

Structural and Mobility Features

In addition to the hydraulic elements, the tool includes structural components such as the handle, base, and wheels. The handle is used to operate the pump, while the base supports the weight of the equipment. The wheels provide mobility, making it easier to position the device beneath the object to be lifted. The saddle, located on top of the lifting mechanism, provides a stable surface for the load to rest upon during operation.

How to Identify Jack Assembly Components

Recognizing the individual components within a lifting tool is crucial for both maintenance and troubleshooting. Each section has distinct characteristics that can help you identify its role in the overall mechanism. Knowing what to look for allows for easier disassembly, repair, and reassembly of the equipment.

Visual Clues for Key Elements

One of the easiest ways to identify each component is by observing its shape, size, and placement within the assembly. For example, the pump is typically a larger, cylindrical part located near the base, while the piston and cylinder are often positioned together in the central section. The release valve can be found near the top, with a small lever or knob to control the release of pressure.

Checking for Functional Markings

Many components will have labels or markings that provide useful information about their function and model compatibility. These markings may be found on the base, handle, or hydraulic system. Pay attention to these details, as they can help you understand the specifications and make it easier to source replacement parts if necessary.