Understanding the individual elements of your garden machinery is essential for proper maintenance and repair. Each piece of equipment relies on a set of critical components that work together to ensure optimal performance. Recognizing these parts can help you troubleshoot issues and carry out efficient repairs.

Identifying the key parts of your equipment can be simplified with a clear overview. Once you familiarize yourself with the structure, you can easily pinpoint the right areas to inspect or replace, making the process of repairing or upgrading more manageable.

In this guide, you will find a breakdown of how to understand the layout of your garden machine’s components. Knowing where each part fits and how they function together enhances your ability to maintain and troubleshoot more effectively.

Understanding Garden Equipment Components

Maintaining any gardening machine requires a clear understanding of its individual components and how they interact. Each element plays a crucial role in the overall function of the equipment, and recognizing them helps in troubleshooting, repairs, and routine maintenance.

Core Elements of the Equipment

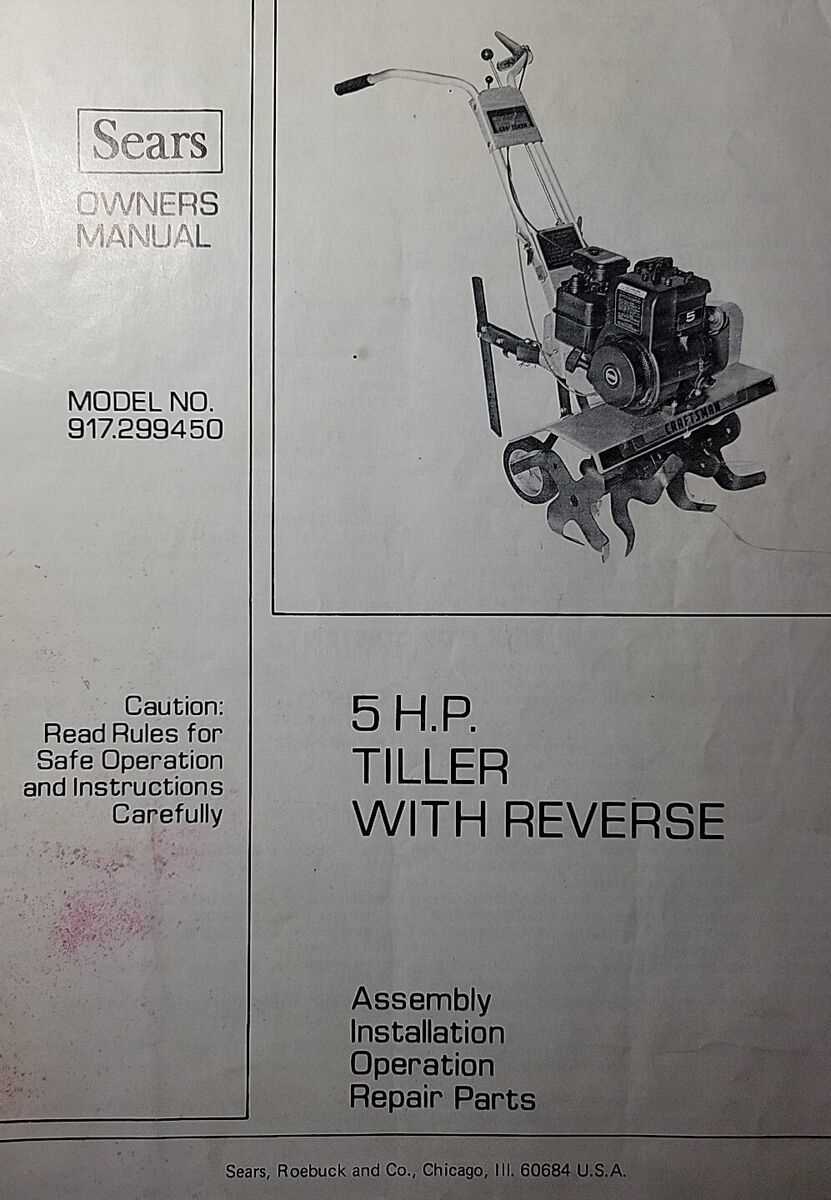

The structure of most machines designed for soil cultivation consists of several essential parts that contribute to their movement and efficiency. Key elements such as the motor, transmission, and handles work in harmony to provide power and maneuverability, ensuring effective use in the garden.

Efficient Troubleshooting and Maintenance

Familiarity with these components allows users to spot issues quickly. Understanding how each part contributes to the operation of the machine ensures better handling during repairs. Regular checks can prevent larger problems by addressing wear and tear early, saving time and costs in the long run.

How to Identify Components on the Diagram

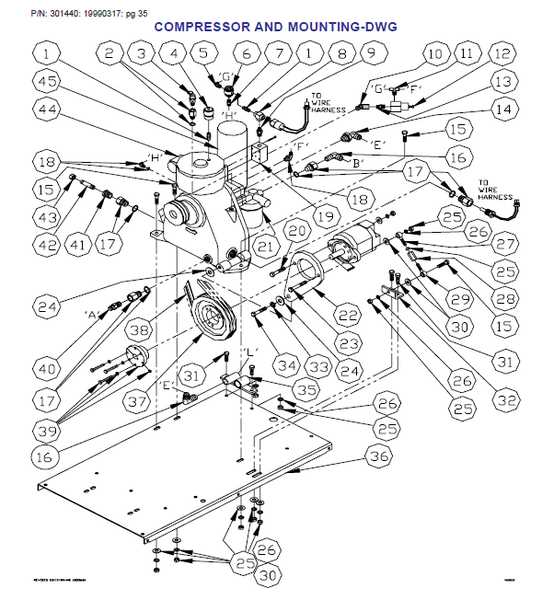

When working with machinery, having a visual guide that clearly labels each individual element is essential for effective repairs and maintenance. A well-labeled illustration enables users to easily spot specific components and understand their role in the machine’s function. By learning how to read these guides, you can quickly identify areas that need attention.

Start by focusing on the key sections of the machine, such as the engine, control handles, and mechanical linkages. These main components are often labeled with their names or numbers, allowing you to cross-reference with the manufacturer’s list. Taking note of any specific details in the diagram, such as size or shape, will help ensure you correctly identify each part for replacement or repair.

Once you are familiar with the layout, use the diagram to cross-check the actual parts of your equipment. By comparing the visual to the machine in front of you, you can easily spot discrepancies or worn-out pieces that need replacement. This method enhances the accuracy of your repair process.

Common Issues and Solutions for Garden Machines

Even the most reliable garden machines can experience issues over time. Whether it’s due to regular wear or a mechanical malfunction, understanding common problems can help you quickly address them. Identifying the source of the issue and knowing the right solution can save you time and money.

One of the most common issues is difficulty starting the machine. This could be caused by fuel problems, a clogged air filter, or issues with the spark plug. Ensuring the fuel is fresh, the filter is clean, and the spark plug is in good condition can resolve many starting problems.

Another frequent problem is poor performance during use. This can occur when the machine is not digging effectively or moving smoothly. It may be due to dull blades, misaligned components, or a malfunctioning transmission. Regular maintenance, such as sharpening blades and checking alignment, can help maintain optimal performance.