Maintaining farming machinery requires a clear understanding of its individual components and how they work together. When dealing with complex equipment, it is essential to be familiar with its structure to ensure proper functioning and longevity. This guide provides a detailed look at the essential elements that make up the machine, helping operators troubleshoot and maintain their tools effectively.

By breaking down the machinery into its core parts, users can identify potential issues and apply the right solutions. Whether it’s for routine maintenance or repair, having a comprehensive understanding of the machine’s layout can save both time and effort. The key is knowing how each element interacts within the system and ensuring that all parts are in optimal condition.

Understanding the mechanics behind your equipment is crucial for efficiency. With a well-detailed breakdown, you can easily perform necessary adjustments or replacements. This approach leads to better performance and a longer service life of the machinery.

Kuhn Hay Tedder Parts Overview

Understanding the individual components of your farming machinery is vital for proper maintenance and functionality. Each section of the equipment serves a specific purpose, and recognizing how these elements contribute to the overall operation can help in troubleshooting and repair. From the frame to the moving parts, each element plays a role in ensuring the machine performs efficiently and effectively in the field.

The system consists of various mechanical parts that work together to handle tasks like spreading and turning. These include gears, rotors, and drive mechanisms that must be regularly checked and serviced. Identifying the function of each component can prevent downtime and extend the lifespan of the equipment. Proper care involves not only regular inspections but also understanding the unique function of each section within the machine.

Understanding the Components of a Tedder

Effective farming equipment relies on a range of interconnected elements that allow it to perform specific functions. Knowing the role of each component is essential for smooth operation and routine maintenance. The machine is composed of both stationary and moving parts that work together to achieve tasks like material manipulation and transportation. Each section of the equipment plays a key role in ensuring optimal performance, and proper knowledge of its components can significantly reduce downtime.

Key Mechanical Elements

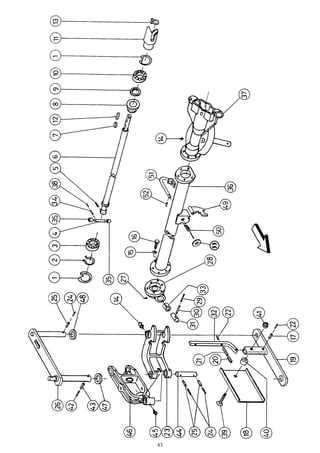

The primary components include the frame, which provides structural support, and the mechanical drive systems that enable movement. The rotating elements are designed to handle specific tasks, such as turning or spreading, and they are powered through the main drive. The gears and linkages connecting these moving parts are crucial for maintaining the efficiency and precision of the machine’s functions. Regular inspection of these moving components ensures that everything runs smoothly and minimizes wear.

Maintenance and Troubleshooting

Routine checks and understanding the function of each part can help identify issues early. Regularly inspecting the drive systems, gears, and rotors helps keep the machinery in working condition. It’s important to know the correct procedures for handling worn or damaged parts to avoid further complications. When a component starts to show signs of wear, timely replacement or adjustment ensures that the equipment remains reliable and efficient for future use.

How to Use the Diagram for Repairs

Repairing farming equipment becomes much easier with a clear understanding of its individual components and their functions. A well-constructed visual guide serves as a map for identifying each part, making it simpler to diagnose issues and carry out necessary fixes. Whether you are replacing a damaged element or performing routine maintenance, having a reliable reference allows for precise and efficient work. This section explains how to leverage such a guide for successful repairs.

Identifying Faulty Components

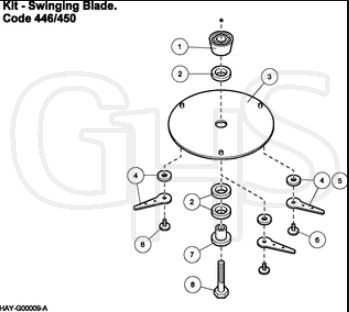

The first step is to locate the malfunctioning part using the guide. Each section of the machine is clearly marked, allowing you to pinpoint the area of concern. Once identified, refer to the visual guide to understand how the component fits into the overall system. Knowing where each piece connects and how it functions helps in selecting the correct replacement or repair approach.

Step-by-Step Repair Process

Once the faulty part is located, use the diagram to understand the disassembly process. Many guides show how to remove the part without damaging other components. Follow the sequence as indicated, paying attention to specific tools or techniques recommended for removal and installation. By carefully following these steps, you ensure that the repair is done properly, minimizing the risk of future issues.