Proper knowledge of your equipment is essential for its longevity and performance. Knowing the structure and function of every individual component ensures that you can operate it with confidence and handle maintenance tasks effectively. A clear understanding of these parts enables you to troubleshoot, repair, or replace worn-out elements when necessary.

In this guide, we will break down the essential components of a popular outdoor tool. By learning the specific features and how they interact, you can easily identify issues and extend the life of your device. Whether you’re a seasoned user or a beginner, this knowledge will empower you to take better care of your machinery and keep it in top condition.

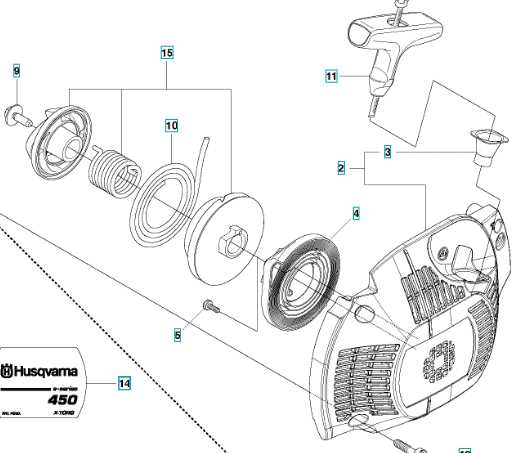

Understanding Husqvarna 450 Parts Diagram

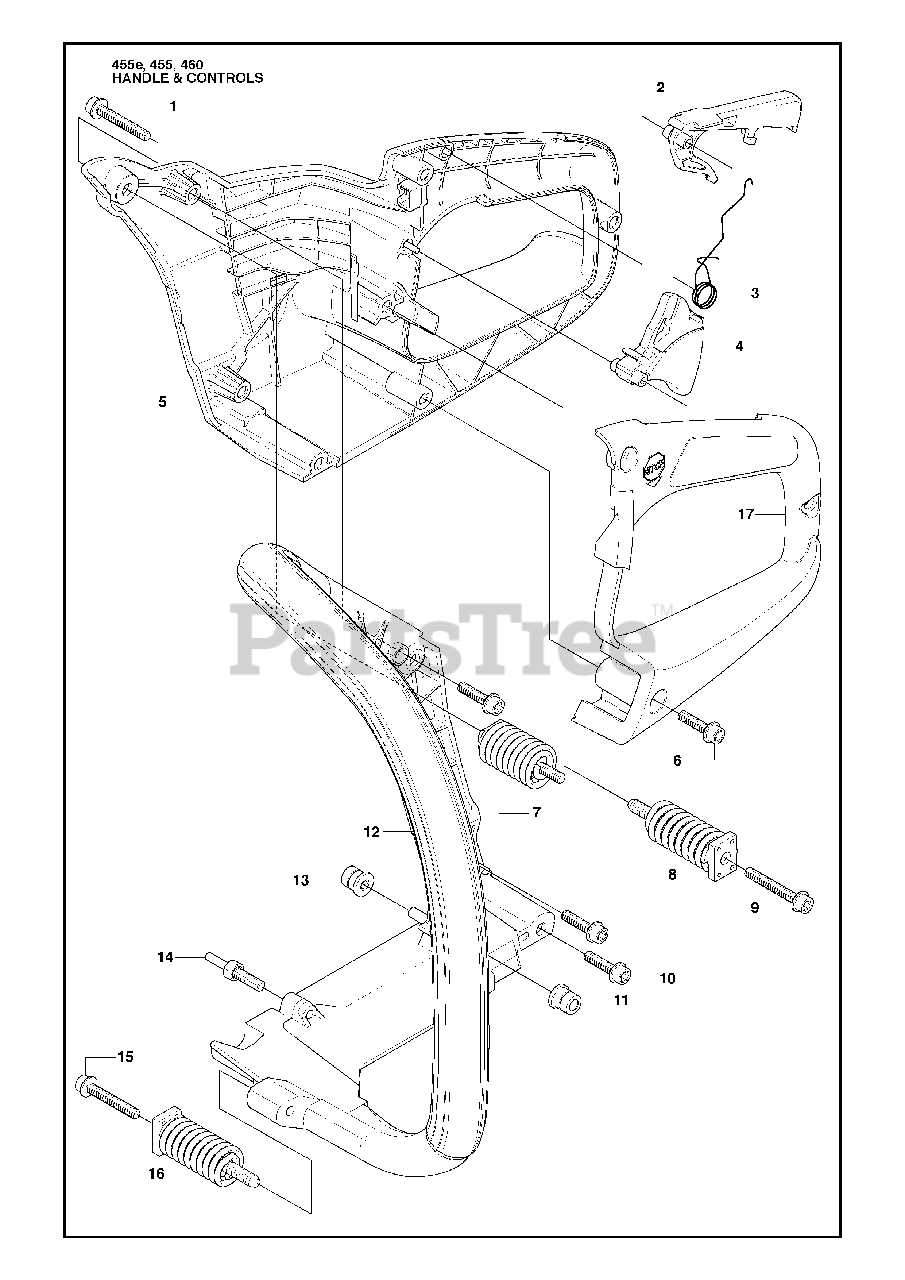

Having a clear visual representation of your tool’s inner components can significantly improve your ability to handle repairs and maintenance. A breakdown of each segment not only helps you identify individual parts but also demonstrates how they fit together to ensure proper function. Familiarizing yourself with the layout makes troubleshooting easier and faster, leading to more efficient handling of any issues that arise.

Each section of the tool serves a specific purpose and interacts with other components to keep the machine running smoothly. By learning the placement and function of these elements, you can better understand potential areas for wear or failure. This knowledge will guide you through identifying problems early and knowing exactly what parts need attention or replacement.

How to Identify Key Components

Understanding the main components of your equipment is crucial for effective maintenance and troubleshooting. Recognizing the essential elements allows you to pinpoint potential issues and address them before they affect the overall performance. Each part is designed to perform a specific function, and knowing where and how they fit together ensures smooth operation.

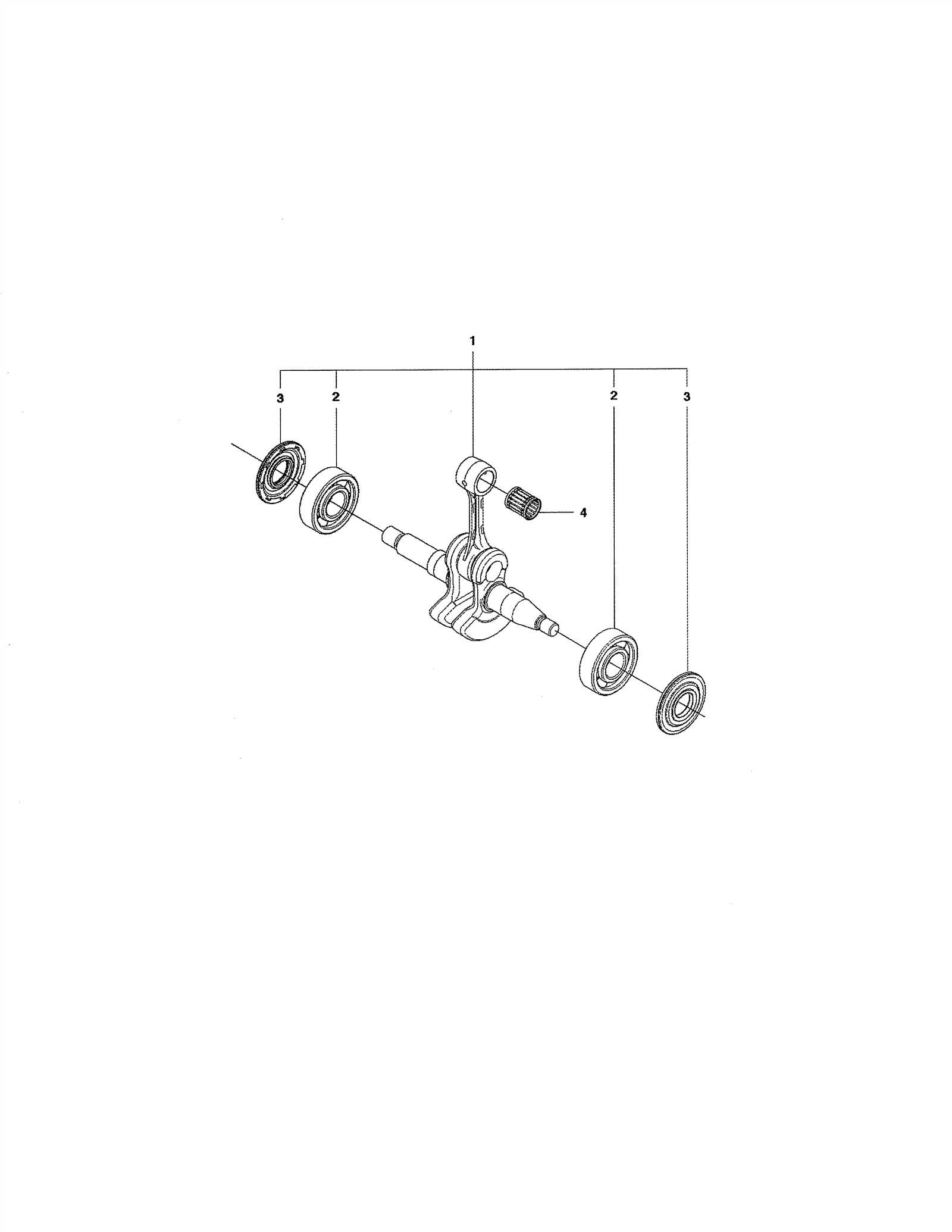

Recognizing the Engine and Power System

The engine is the heart of your tool, driving its movement and power. It’s important to identify the key elements such as the carburetor, spark plug, and fuel system. These parts play a critical role in maintaining proper operation. Regular inspection of these components helps in avoiding fuel-related issues or poor starting performance.

Understanding the Drive and Cutting Mechanism

The cutting system is one of the most important areas to focus on. Key components like the bar, chain, and tensioning system need to be properly aligned for efficient cutting. Make sure that these parts are well-maintained to avoid any unnecessary wear and tear that could hinder cutting performance.

Tips for Maintaining Your Chainsaw

Regular upkeep is essential for ensuring the longevity and performance of your outdoor tool. By following a few key practices, you can prevent costly repairs and keep your equipment in optimal working condition. Consistent care also reduces the risk of malfunction during use, allowing for more efficient and safer operation.

Keep the Cutting System Sharp

A sharp cutting edge is crucial for efficient operation. Regularly inspect the bar and chain for signs of wear or damage. Lubricate the chain to reduce friction and keep the system running smoothly. If you notice any dullness or difficulty cutting, it’s time to sharpen or replace the chain.

Check the Fuel and Air Filters

The fuel and air filters are vital for maintaining smooth engine operation. Make sure to replace the air filter regularly, especially if you use your equipment frequently or in dusty conditions. Also, check the fuel system to avoid clogging or degradation of fuel quality, which can cause starting problems or decreased performance.