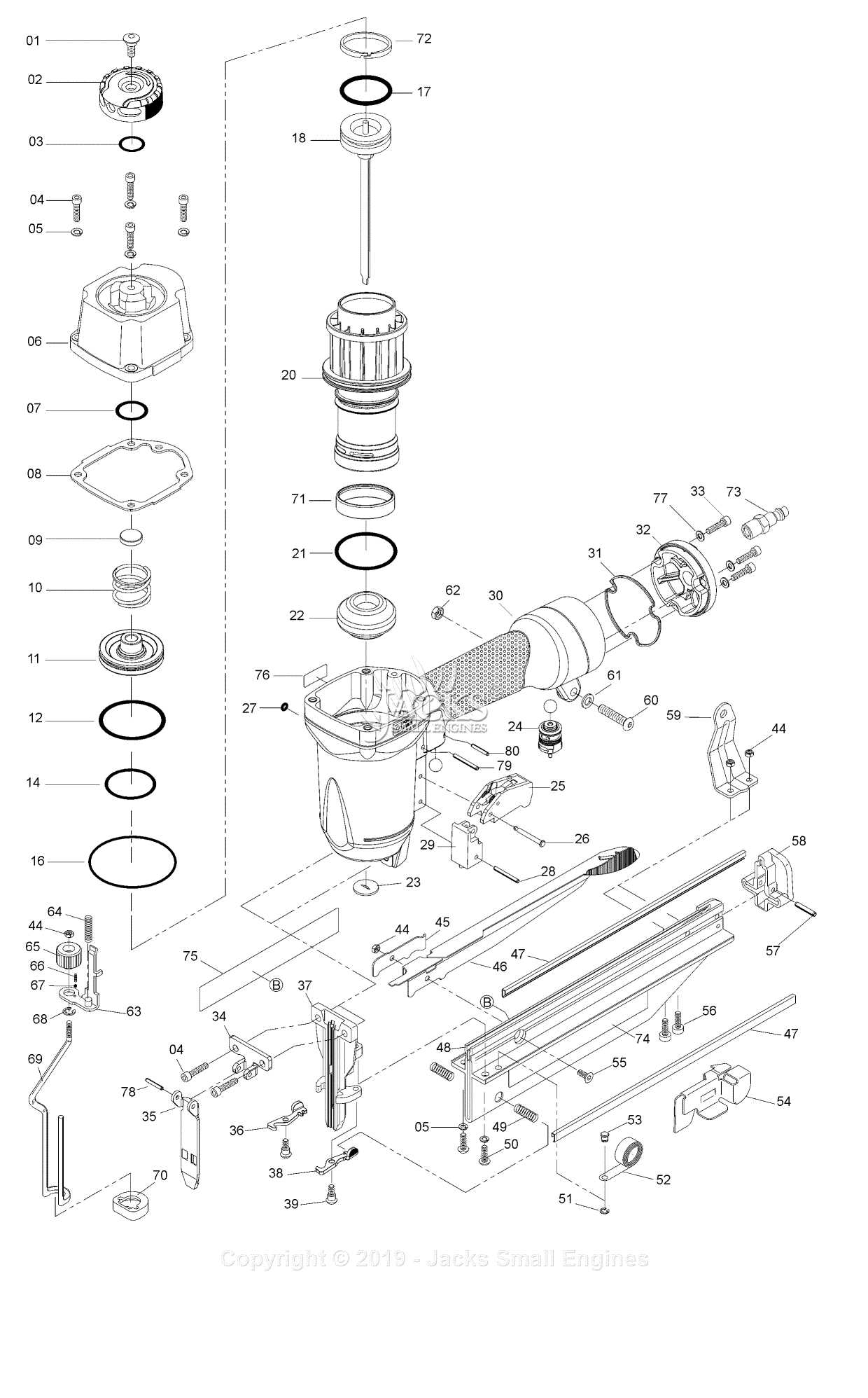

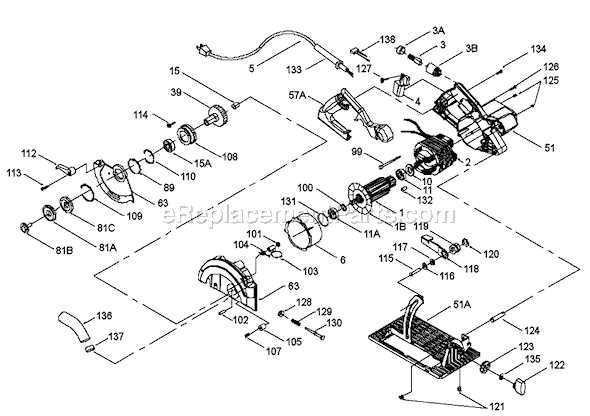

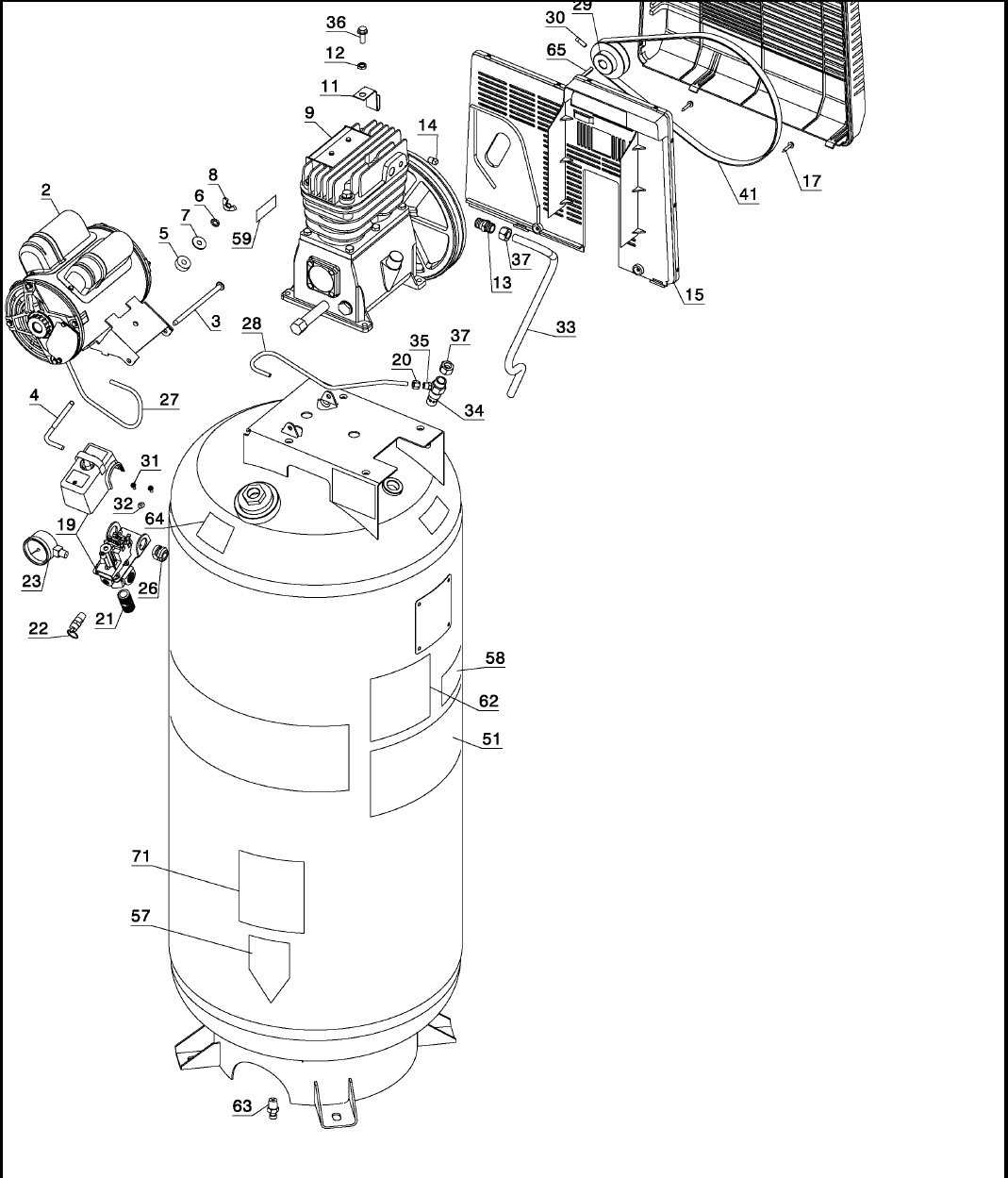

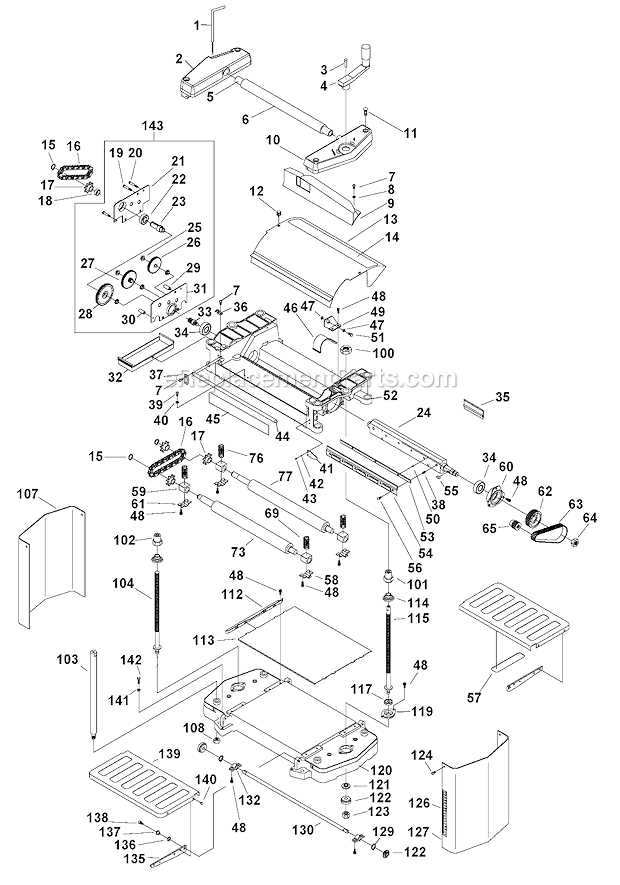

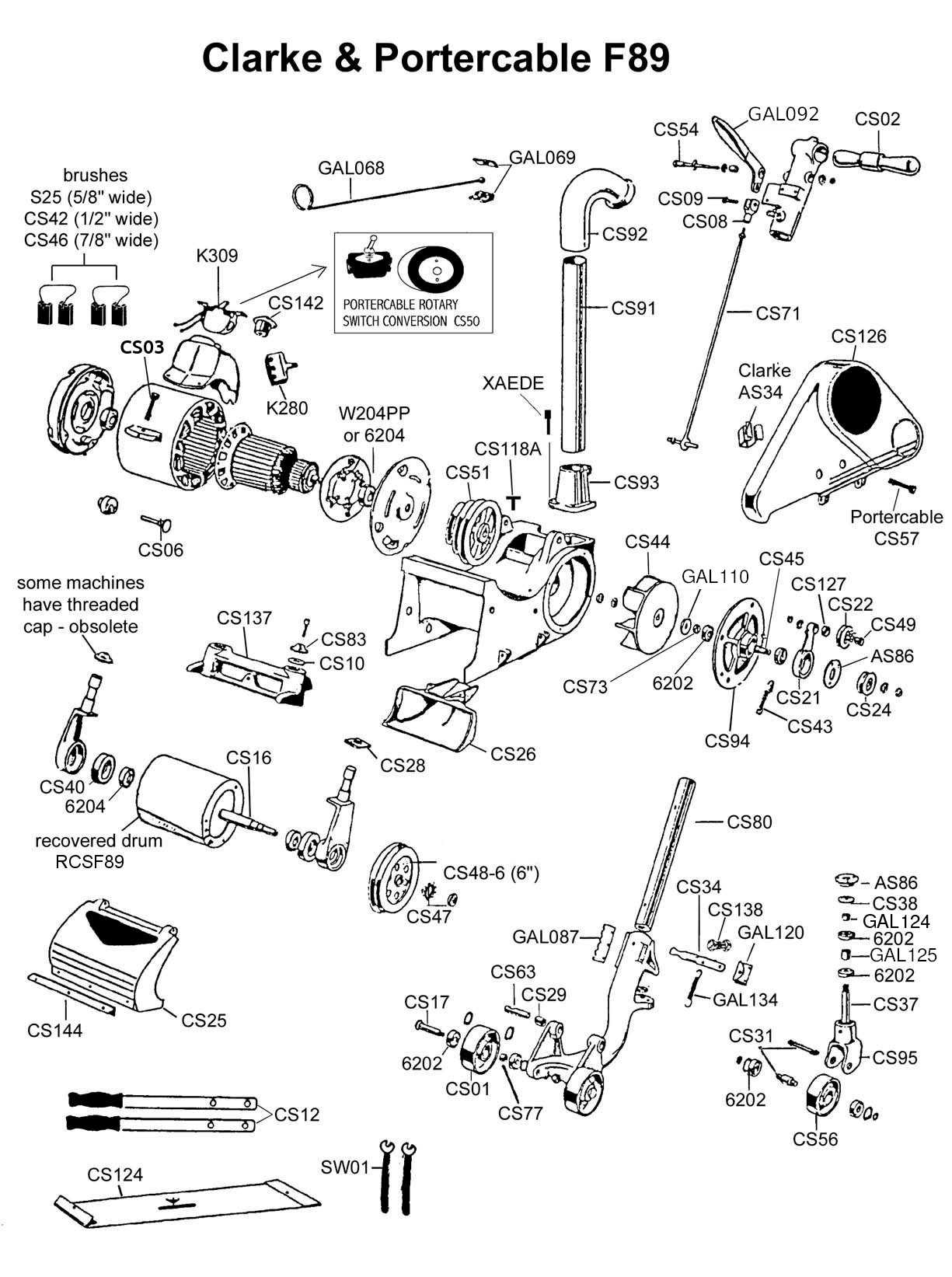

When it comes to maintaining your equipment, a clear understanding of its internal structure is essential. Recognizing each element’s role helps in troubleshooting, repair, and proper upkeep. This section will guide you through the visual representation of all key pieces, showing how they interact to ensure your tools function optimally.

Having access to an accurate illustration of your tool’s layout can save time and reduce confusion during repairs. By studying the breakdown, you can identify worn or damaged elements and understand the overall assembly. This knowledge allows you to make informed decisions when replacing parts or seeking professional help.

Identifying each individual component ensures that you can easily spot any issues that may arise, leading to quicker solutions and extended lifespan for your equipment. Through careful examination and proper maintenance, your tools will continue to perform at their best.

Understanding Tool Component Breakdown

Every piece of equipment consists of various internal elements that work together to ensure its functionality. Knowing how these components fit into the overall system allows for better understanding and maintenance. Each part has a specific function, and recognizing their placement and connections can make troubleshooting and repairs more efficient.

Visual representations of the tool’s inner structure help users pinpoint exactly where each element belongs. This detailed layout serves as a valuable resource for anyone looking to disassemble, repair, or replace parts. A clear view of the arrangement provides clarity, reducing the chances of mistakes or misplacements during the process.

By thoroughly studying the breakdown, users gain insight into the most common issues that may arise within the mechanism. Understanding how different components interact also makes it easier to spot wear and tear, allowing for timely replacements that ensure continued performance and durability.

How to Identify Key Components

To ensure your equipment operates at its best, it’s important to recognize the main elements within its structure. Identifying these key components allows you to assess their condition, spot potential issues, and replace or repair them when necessary. This knowledge simplifies maintenance and helps you avoid unnecessary complications during repairs.

Start by familiarizing yourself with the overall layout. Take note of the most visible parts, such as the motor, housing, and operational buttons. These are often central to the functionality and can be the first to show signs of wear or malfunction.

Next, examine the smaller components that support the major elements. These include gears, switches, and connectors that allow the tool to function smoothly. Understanding the role of each smaller part ensures you can quickly diagnose problems when the device stops working properly.

Using a visual reference, such as a breakdown chart or guide, will make it easier to recognize and understand where each component fits. With this approach, you can efficiently identify issues and make informed decisions about repairs or replacements.

Step-by-Step Guide to Tool Assembly

Assembling your tool correctly is essential to ensure its proper functioning. Each component must be securely connected in the right sequence, as any mistake can lead to malfunctions or safety hazards. This guide will walk you through the steps needed to assemble your equipment efficiently and effectively.

Prepare and Organize Components

Before beginning the assembly, ensure all the necessary pieces are present and organized. This will save time and prevent confusion during the process. Check the list of required elements and align them according to their size and function.

Follow the Assembly Instructions Carefully

Pay attention to the sequence in which the components should be attached. Starting from the main housing, carefully install the essential parts one by one, making sure each piece fits properly and securely. Use the recommended tools to avoid damaging any delicate components.

| Step | Component | Action |

|---|---|---|

| 1 | Main Housing | Secure the central body and ensure stability. |

| 2 | Motor | Insert and fasten the motor into place. |

| 3 | Switches | Attach switches in the designated slots. |

| 4 | Other Attachments | Install any additional accessories or attachments. |

Once you’ve completed the assembly, double-check all connections for security and test the tool to confirm it operates as expected. Proper assembly ensures your equipment runs smoothly and is ready for use.

Visualizing the Components Breakdown Process

Understanding the internal structure of your tool is crucial for efficient maintenance and repair. By visualizing the breakdown of all essential elements, you can better understand how each part contributes to the overall functionality. This step-by-step approach helps you quickly identify issues and ensures the assembly process is easier to follow.

One of the most effective ways to break down the components is through clear visual aids that show the relationships between parts. Here’s how to approach the process:

- Start with a general overview: Begin by observing the full layout, which shows the tool’s major sections and how they connect to each other.

- Break it into smaller groups: Identify the larger elements such as the motor, housing, and switches. From there, break them down into smaller components like gears and connectors.

- Use detailed illustrations: Diagrams that zoom in on specific areas make it easier to focus on individual parts. These details help you spot potential issues in specific sections.

By following this structured approach, you’ll gain a deeper understanding of how your tool operates. You can also keep track of which components need replacement or maintenance, streamlining the repair process.

Tips for Efficient Parts Replacement

Replacing worn or damaged components is a crucial part of maintaining any equipment. Doing so efficiently ensures that your tool remains in top condition, while also saving time and reducing unnecessary costs. By following the right procedures and using the appropriate resources, you can streamline the replacement process and avoid common mistakes.

Start by carefully identifying the faulty elements. Use a visual guide or breakdown to pinpoint exactly which part needs to be replaced. This avoids confusion and ensures you order the correct replacement. Once you have the new component, follow the assembly instructions to reinstall it properly.

Here are some tips for replacing components efficiently:

- Use the right tools: Ensure you have the necessary tools to safely remove and install parts, such as screwdrivers, wrenches, or pliers.

- Check compatibility: Always verify that the replacement part is compatible with your tool’s model to avoid installation issues.

- Take notes: While disassembling, take notes or photos to remember the correct order of assembly. This will make reassembly much easier.

- Test the tool: After replacing the component, test the equipment to ensure it is working properly and the new part fits seamlessly.

By following these steps, you can efficiently replace components, ensuring your tool performs optimally and lasts longer.