Proper maintenance of outdoor machinery is essential for ensuring its longevity and efficiency. Whether it’s a tool for clearing pathways or a larger machine for handling heavy snow, understanding its components is crucial for effective upkeep. A comprehensive view of each element allows for timely repairs and optimal performance during challenging weather conditions.

By familiarizing yourself with the inner workings of your machine, you can troubleshoot issues quickly, reduce the need for professional repairs, and maximize the life of your equipment. Regular inspections and replacements based on wear patterns are key to maintaining its functionality. Knowing what each part does and how they interact makes it easier to handle any problems that arise.

In this guide, we will explore how to identify and understand the various elements that make up your equipment, offering clear guidance on their roles and providing valuable insights for maintaining and repairing them. This knowledge empowers you to keep your machine in top condition, ready to tackle any job at hand.

Understanding Your Equipment Components

When it comes to maintaining outdoor machinery, understanding the various elements that make up the system is vital. Each component serves a specific function, and recognizing how they all interact is essential for ensuring smooth operation. A comprehensive understanding of these elements makes it easier to identify issues, perform routine maintenance, and carry out necessary repairs.

Main Functional Units

At the core of any outdoor machine, there are several key units that allow it to perform its task efficiently. These include the motor, the auger assembly, and the chute system. The motor drives the main operation, while the auger and chute work together to move material and direct it accordingly. Recognizing how these systems work together enables quicker troubleshooting and more accurate maintenance.

Identifying Wear and Tear

Over time, certain components may wear out due to constant use and exposure to harsh conditions. The most common signs of wear include corrosion, fraying, or cracking, especially in the moving parts. Regular inspection of these elements ensures that any damage is addressed before it affects performance. Replacing worn-out components promptly can prevent costly repairs and ensure that the equipment operates at peak efficiency.

Identifying Key Parts for Maintenance

Effective maintenance starts with the ability to recognize the critical components that ensure optimal performance. By identifying these key elements, you can focus your attention on areas that require the most care and attention, reducing the chances of failure during operation. Regular checks of these vital sections help prevent long-term damage and keep the machinery functioning smoothly.

Engine and Power System

The engine is the heart of the equipment, and keeping it in good condition is essential for efficient operation. Regular oil changes, air filter checks, and spark plug maintenance are necessary to ensure the motor runs smoothly. Any irregularities in engine performance should be addressed immediately to prevent larger issues from developing.

Auger and Chute Mechanisms

The auger and chute systems play a crucial role in material handling. Ensuring that these components are free from obstructions and properly aligned is vital for their functionality. Check for wear and tear on the blades, and replace any damaged sections to avoid compromising the machine’s ability to clear effectively.

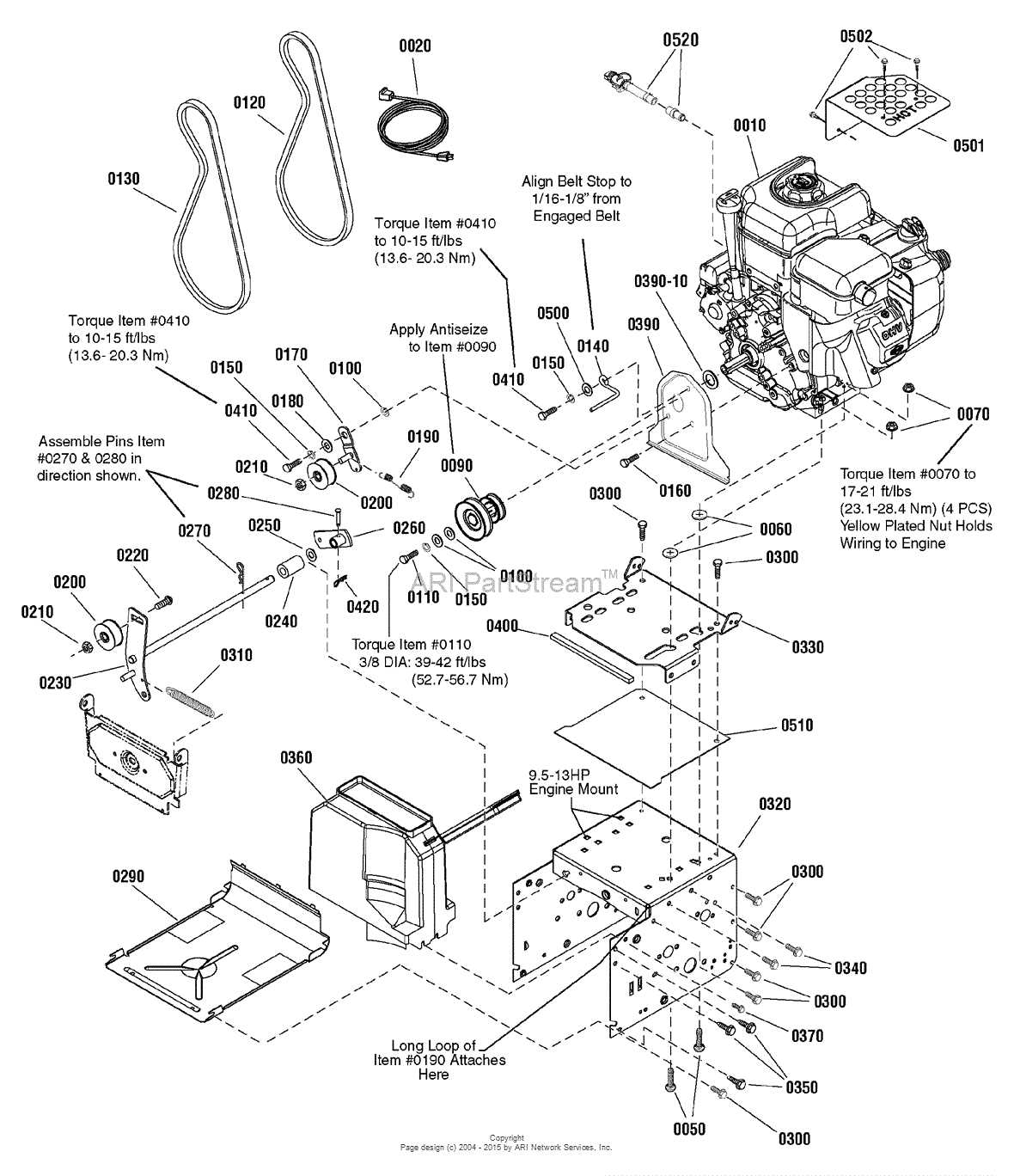

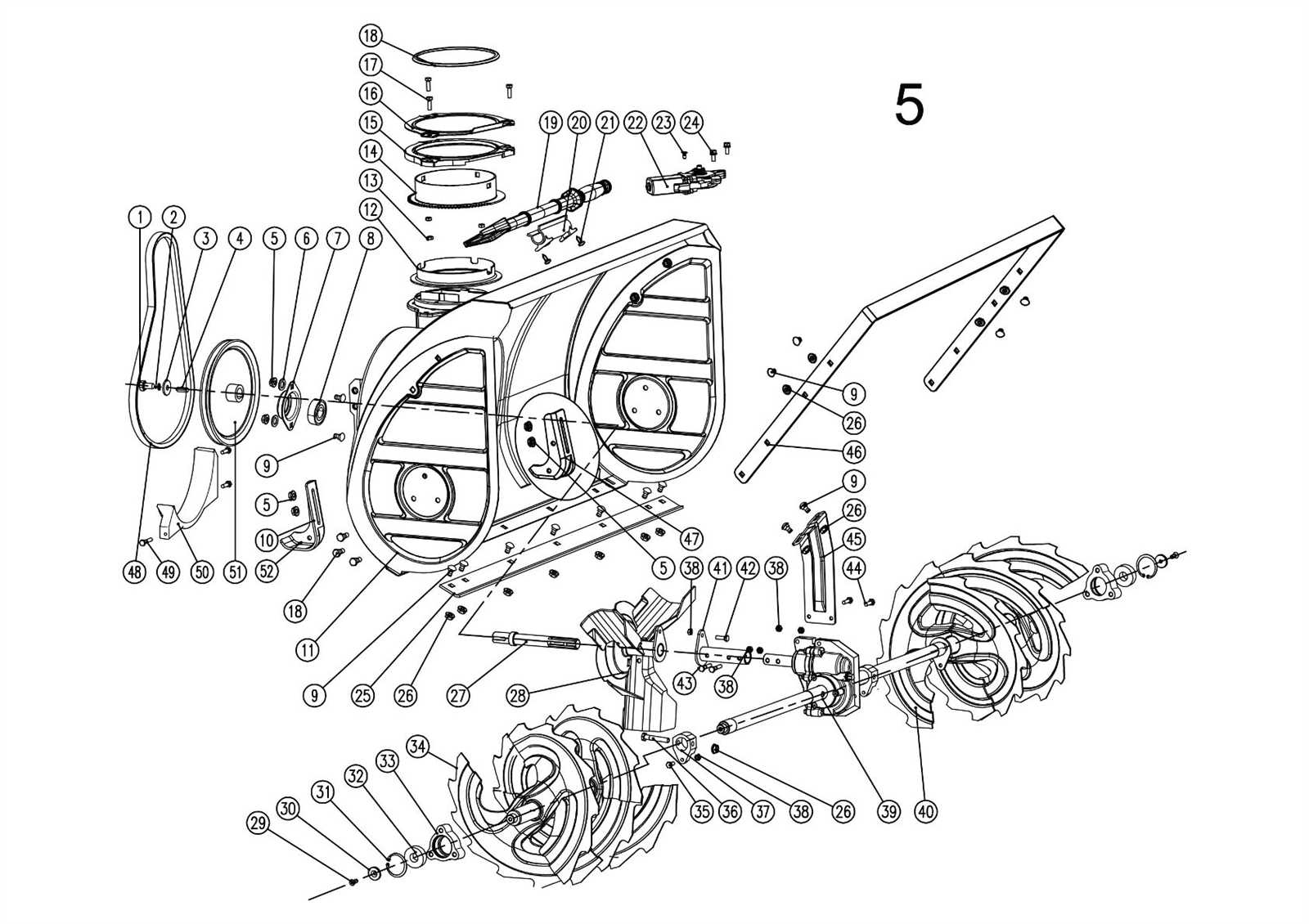

How to Read the Equipment Component Breakdown

Understanding how to interpret the breakdown of your equipment’s components is key for effective repairs and maintenance. A clear, organized view of all the essential parts helps identify their individual functions and how they work together. By following the provided illustrations and labels, you can easily locate each part, making it simpler to diagnose problems or replace worn elements.

Each section of the breakdown typically includes labels and numbers that correspond to specific parts. These labels often reference part names or codes that help identify the correct components. When reading, focus on the numbering system and any accompanying descriptions to ensure you are selecting the right replacement or performing the correct maintenance task.