Proper knowledge of a snowmobile’s internal structure is essential for every rider and mechanic. Having a clear understanding of the various elements that make up your machine helps ensure optimal performance and longevity. By recognizing the different sections and their functions, you can carry out maintenance tasks with confidence and efficiency.

Detailed breakdowns of the mechanical features assist users in identifying problems and planning repairs. Visual guides offer an invaluable resource for those looking to replace specific parts or troubleshoot malfunctioning systems. Whether you are an experienced rider or a novice enthusiast, these tools will aid you in navigating the complexities of snowmobile maintenance.

Clear depictions provide a convenient reference when it comes to identifying and replacing components. Understanding where each part fits into the machine’s overall design allows for faster and more accurate repairs, ultimately improving your snowmobile experience on the snow.

Understanding Snowmobile Component Breakdown

A comprehensive visual guide to the inner workings of a snowmobile is crucial for maintaining and repairing the machine. By offering a detailed layout, these resources allow users to pinpoint each individual piece and its function. Recognizing how the various components interconnect ensures a deeper understanding of the overall system, making it easier to diagnose issues and perform necessary repairs.

These illustrations highlight key mechanical elements and their placement within the vehicle. A well-organized chart helps users quickly find the correct parts for replacement or inspection. The clarity provided by such resources makes it easier for both seasoned professionals and new users to navigate the complexities of snowmobile maintenance.

With proper guidance, identifying worn or malfunctioning pieces becomes a straightforward task. These visual representations support effective troubleshooting and prevent unnecessary errors during repairs, helping to keep your machine running smoothly throughout the season.

How to Read a Snowmobile Component Breakdown

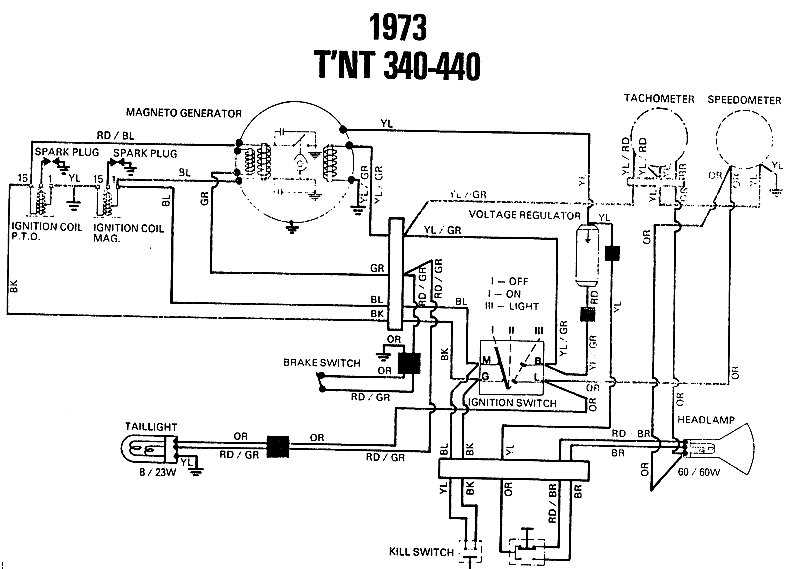

Interpreting a visual representation of a snowmobile’s mechanical structure is essential for proper maintenance and repair. These guides offer a detailed map of the machine, with each part labeled clearly. To effectively read and utilize this resource, it’s important to understand how each section is organized and how different components are connected within the system.

Step-by-step identification is the key to fully understanding these charts. The first step is to familiarize yourself with the layout, which typically starts with the main frame and branches out to smaller components. By following the lines and labels, you can easily trace the parts and determine their position within the system.

Understanding symbols and terminology is equally important. These guides often use specific icons and terms to represent each component. Once you become accustomed to the format, you will be able to quickly identify parts and navigate through the diagram to find what you need.

Common Snowmobile Components Explained

Understanding the essential mechanical elements of a snowmobile is crucial for effective maintenance and repairs. Each machine consists of several key components, each with a specific function that contributes to the overall performance. Familiarity with these parts will help riders and mechanics troubleshoot issues and carry out repairs with greater precision.

Among the most common elements are the engine, which powers the vehicle, and the track system, responsible for movement. The clutch assembly plays a critical role in transferring power from the engine to the track, while the steering system enables directional control. Additionally, the exhaust system ensures proper ventilation and reduces emissions.

Each of these components must work in harmony to ensure the snowmobile operates smoothly. Regular checks and understanding their functions help prevent mechanical failure and extend the vehicle’s lifespan. With a solid grasp of these common elements, users are better equipped to handle repairs and ensure optimal performance in all conditions.

Identifying Essential Snowmobile Components

Properly identifying the core mechanical elements of a snowmobile is essential for efficient repairs and maintenance. Recognizing each part’s role within the system helps ensure smooth operation and effective troubleshooting when issues arise. Here, we will explore some of the most crucial components that every rider should be familiar with.

Key Components to Identify

- Engine – Powers the vehicle and drives all systems, including the track.

- Track – Provides traction, allowing movement across snowy terrains.

- Clutch Assembly – Connects the engine to the track, controlling the power transfer.

- Steering Mechanism – Directs the snowmobile, allowing for control and navigation.

- Suspension System – Ensures stability and comfort, absorbing shocks during rides.

Why Identification Matters

Recognizing these components helps when performing routine checks or addressing mechanical issues. By understanding how each part works and where it is located, riders can quickly troubleshoot problems and prevent further damage. With a basic knowledge of these essentials, any snowmobile enthusiast can handle their vehicle with confidence and ease.

Benefits of Using Component Layouts

Utilizing a visual breakdown of a snowmobile’s mechanical structure provides several advantages, especially for those handling repairs or maintenance. Such tools offer a clear representation of all the key components, making it easier to identify specific parts and understand their function within the system. This leads to more accurate diagnostics and efficient fixes.

Improved Accuracy in Maintenance

Having a detailed reference to guide maintenance tasks eliminates confusion, allowing users to quickly locate parts that need attention or replacement. This level of clarity minimizes errors and speeds up the repair process, reducing downtime and increasing overall vehicle performance.

Time and Cost Savings

By using a well-structured guide, users can avoid unnecessary disassembly or incorrect part purchases. Identifying the exact component that needs replacement prevents costly mistakes and ensures that the right parts are acquired. This results in less waste and more cost-effective maintenance.