When maintaining outdoor equipment, understanding its individual components is crucial for proper functionality and long-term performance. The efficiency of these machines depends largely on the arrangement and condition of various elements working together. Identifying how each part contributes to the overall operation can help users troubleshoot issues and perform essential maintenance.

By examining the structure of the system, it becomes easier to pinpoint the cause of malfunctions, ensuring a smoother and more reliable cleaning experience. Knowledge of the various components and their functions can also extend the lifespan of the device, minimizing repair costs and enhancing performance over time.

Understanding the High-Pressure Cleaning System Layout

In order to fully comprehend how a high-performance cleaning device functions, it’s essential to break down the arrangement of its internal components. Each section plays a unique role, and their interaction determines the efficiency and effectiveness of the machine. A detailed look at these elements helps users identify issues quickly and understand the maintenance required for optimal performance.

Main System Components

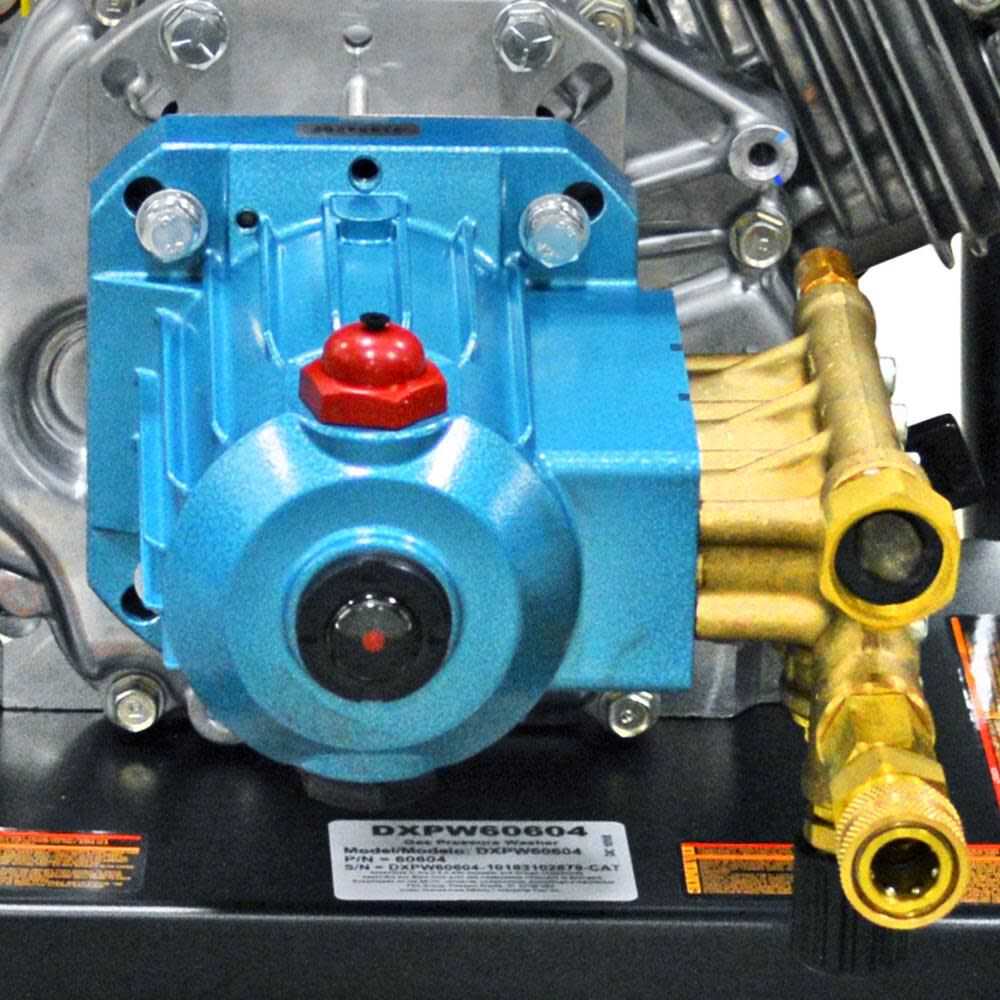

At the heart of the equipment lies the engine, which drives the core mechanism that generates force. Surrounding it are various accessories designed to optimize fluid movement, manage pressure, and regulate temperature. Knowing the location and function of each part ensures smoother operation and reduces the likelihood of breakdowns.

How Components Work Together

These internal elements must work seamlessly together to deliver consistent results. The connections between parts must be secure to prevent leakage and ensure steady operation. Understanding how each piece interacts with the others helps in troubleshooting and fixing common problems, ensuring longevity and reliability in the machine’s use.

Key Components of High-Performance Cleaning Equipment

Every effective cleaning machine relies on several crucial components that ensure its operation. These elements work in tandem to provide the power and functionality needed for heavy-duty cleaning tasks. Familiarity with these core components allows for better maintenance, troubleshooting, and efficient use of the equipment over time.

Among the most important components are the motor, which drives the machine’s power output, and the water delivery system, which directs flow and ensures proper pressure levels. Additionally, the filtration system prevents debris from damaging the internal mechanisms, while the hose and nozzle ensure accurate and controlled spraying. Understanding how these components interact helps maintain peak performance and avoid common issues during use.

Common Issues and Maintenance Tips

Even the most durable cleaning equipment can face occasional problems. Regular maintenance and proper care can prevent many of these issues from affecting performance. By understanding the most common malfunctions and knowing how to resolve them, users can extend the lifespan of their machines and keep them running smoothly.

Frequent Problems and How to Fix Them

One of the most common issues is insufficient water flow, which may be caused by clogged filters or damaged hoses. Another frequent problem is inconsistent power output, often due to engine or pump malfunctions. Identifying the root cause of these issues early can help users fix them before they escalate into more serious complications.

Proactive Maintenance Steps

Regularly checking and replacing worn-out components like seals, filters, and hoses is essential to ensure efficient operation. Additionally, cleaning the machine after each use and storing it in a dry, safe location can prevent rust and other long-term damage. Routine checks of the engine, pump, and water delivery system will also contribute to the longevity of the equipment.