When it comes to maintaining and repairing outdoor power equipment, having a clear understanding of its components and assembly is essential. Whether you’re a seasoned professional or a DIY enthusiast, knowing how the different parts fit together ensures proper functioning and efficient repairs.

Accurate knowledge of each component allows for easier troubleshooting, part replacements, and overall equipment longevity. By familiarizing yourself with the individual pieces and their roles, you can avoid costly mistakes and downtime.

Proper assembly guides and clear diagrams can make all the difference when working on complex machinery. With the right resources, you can confidently tackle any maintenance task and ensure your equipment performs at its best.

Stihl FS 131 Parts Overview

Understanding the structure and key components of any outdoor power tool is crucial for effective maintenance and repairs. Every piece plays a significant role in ensuring smooth operation and longevity. When examining these devices, it’s important to focus on the individual elements that contribute to overall performance.

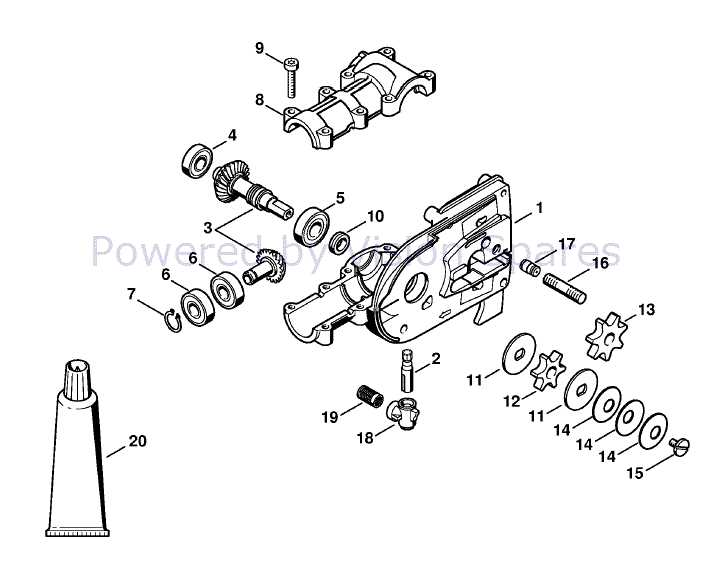

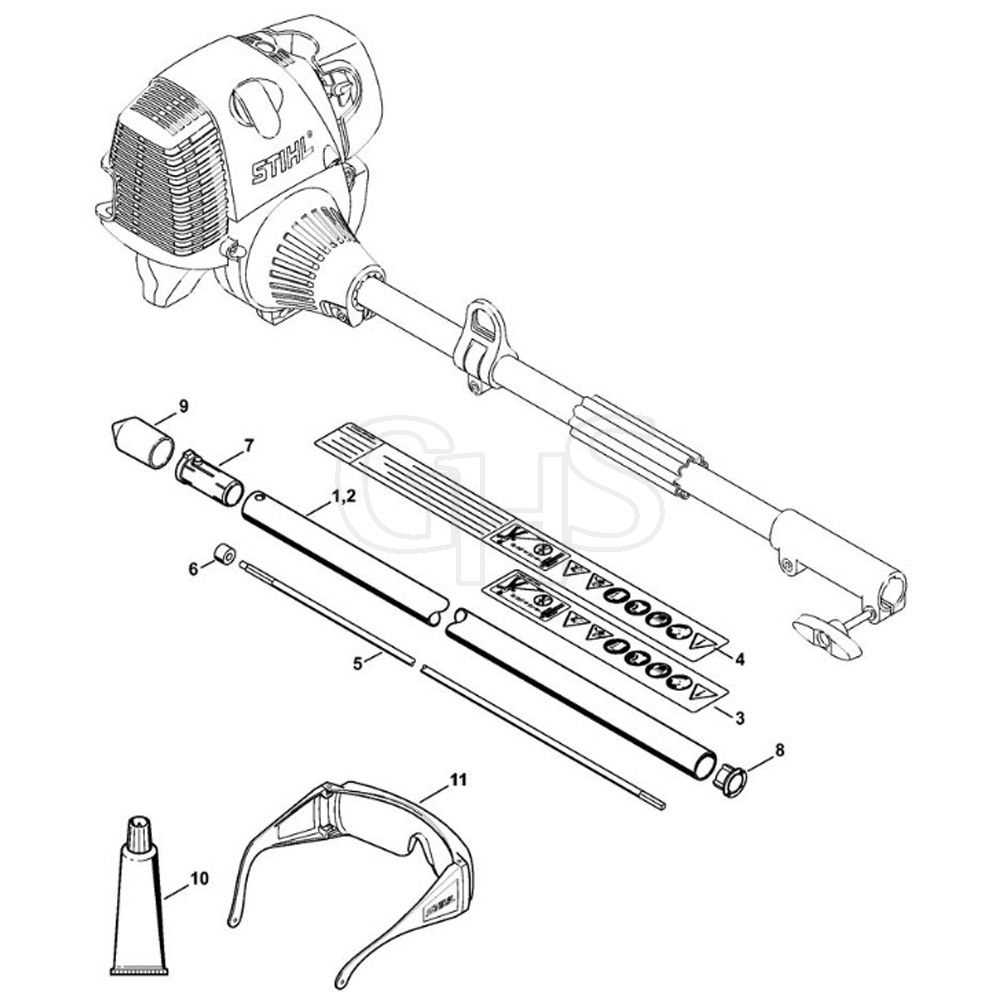

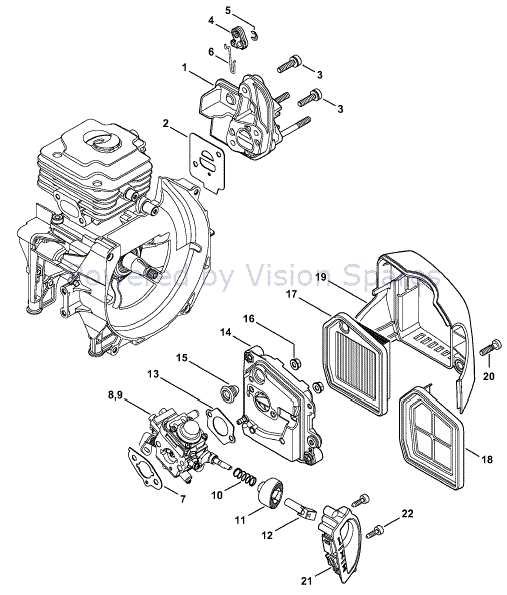

Essential components typically include the engine assembly, cutting mechanism, and various support structures. These parts work in harmony to achieve optimal results during operation. Knowing the function of each element helps to prevent breakdowns and ensures timely replacements.

Regular inspection and familiarity with the various components help users identify worn or damaged parts early, preventing further damage and reducing repair costs. This knowledge also improves the efficiency of routine maintenance and prolongs the lifespan of the equipment.

Understanding the Assembly of FS 131

For any mechanical tool, understanding how its components fit together is essential for effective usage and repair. The assembly process ensures that all elements function cohesively, allowing for maximum performance and minimal wear. Having a clear picture of how each part connects can make maintenance tasks much easier and more efficient.

Key Structural Elements

The foundation of this machine consists of several primary sections, including the engine housing, drive components, and cutting system. These major units work in tandem to perform their specific tasks, and each connection point is crucial for the smooth operation of the tool. Recognizing how these components interrelate helps ensure proper reassembly and troubleshooting.

Assembly Process for Maintenance

During routine maintenance or repairs, understanding the order of assembly is just as important as knowing the individual parts. Reassembling the device correctly ensures optimal functionality and prevents issues caused by improper assembly. By following a logical sequence and consulting the assembly guidelines, users can maintain their equipment in top condition.

How to Replace FS 131 Components

Replacing worn or damaged components is a necessary part of maintaining any outdoor power tool. Understanding the proper steps for replacement ensures the machine continues to function at its best. By following a clear process, users can carry out repairs themselves, saving time and money.

Preparation and Safety

Before starting the replacement process, ensure the tool is powered off and completely cooled down. Gather all necessary tools and replacement parts. Safety precautions such as wearing gloves and eye protection are crucial to avoid injury during the procedure.

Step-by-Step Replacement

Begin by removing the damaged or worn component carefully, making sure to note how it is attached. Once removed, install the new part in the same manner, ensuring all connections are secure. Proper alignment is critical for smooth operation, so double-check the installation before powering on the device.