When working with mechanical equipment, it’s essential to understand the role of each element within the system. By breaking down the various components, users can gain a clearer view of how the machinery functions and how to maintain it effectively.

Proper knowledge of each individual piece can help identify potential issues early, allowing for quicker repairs and prolonged usage. Knowing the layout and relationship between these elements can significantly enhance overall performance and safety.

Maintenance becomes more efficient when one is familiar with the essential components. By learning how they interact, it’s easier to troubleshoot and address any concerns promptly, ensuring the equipment remains in top working condition for longer periods.

Understanding Power Tool Components

Each mechanical device relies on a series of interconnected components that work together to ensure optimal functionality. Understanding these elements is crucial for anyone looking to maintain or repair the equipment effectively. When familiar with the role of each piece, users can identify issues quickly and extend the tool’s lifespan.

The Role of Key Elements

The main elements of any tool include the motor, valves, and pressure systems. Each of these parts contributes to the overall efficiency and performance of the machine. The motor generates the necessary power, while the valves control the flow and distribution of energy. The pressure system ensures that the tool operates under safe and optimal conditions.

Common Issues and Troubleshooting

When one component malfunctions, it can impact the entire system. For example, a damaged motor can cause the device to underperform, while an issue with the pressure system might result in inconsistent output. Recognizing the signs of trouble early can save time and reduce repair costs. Regular inspection and understanding of how each element functions are key to preventing breakdowns.

How to Identify Key Parts in Diagrams

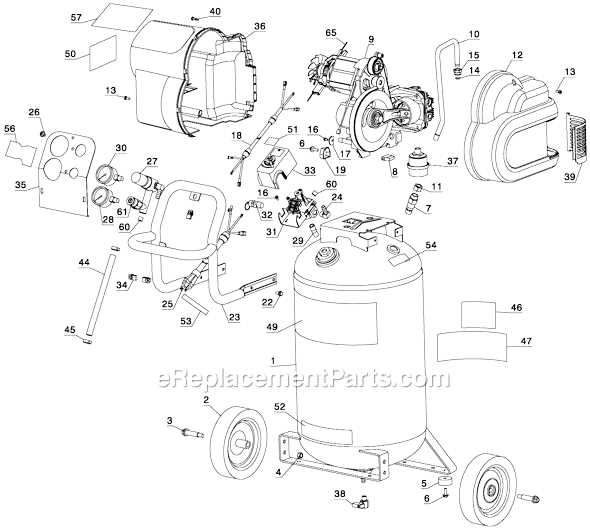

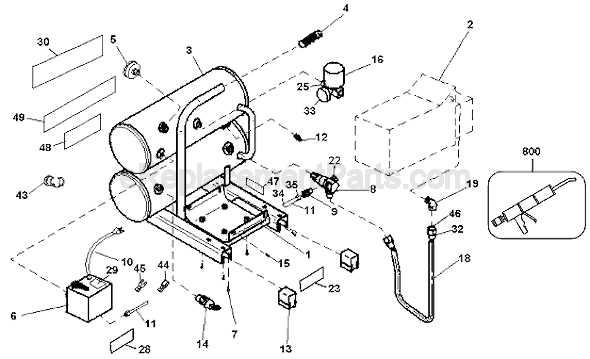

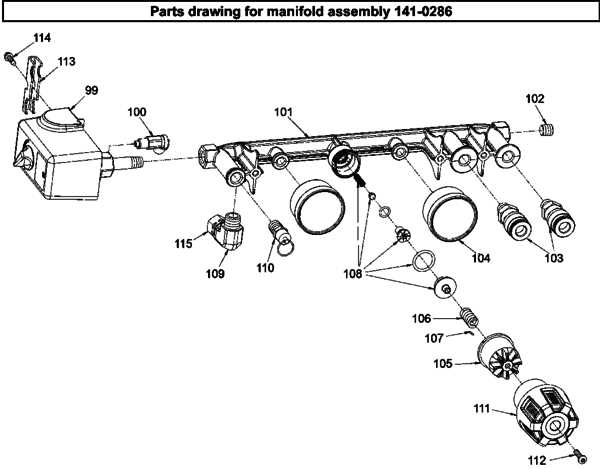

Understanding technical visuals is crucial when dealing with machinery. Diagrams serve as a valuable tool to recognize the location, function, and relationship of various components within a system. Knowing how to interpret these visuals can significantly improve maintenance and repair processes.

Key Symbols and Indicators

When studying a technical illustration, it’s important to familiarize yourself with the common symbols used for each element. Components are typically represented by clear shapes, lines, or labels. Pay attention to these markings as they will help you identify parts quickly. Some diagrams may also include numbered references that correspond to a detailed list of descriptions.

Interpreting Connections and Functions

Beyond just identifying each individual part, it’s essential to understand how they work together. Diagrams often show how elements are connected through lines or arrows, indicating flow and interaction. By focusing on these connections, you can gain a deeper understanding of how the system operates as a whole, which is vital for troubleshooting and repairs.

Common Issues and Repair Solutions

Over time, machinery can experience wear and tear that affects its performance. Recognizing common problems early allows for timely interventions, preventing further damage and costly repairs. Understanding these typical issues and knowing how to resolve them can significantly improve the longevity and efficiency of the tool.

Performance Drops and Lack of Power

One of the most frequent issues is a noticeable drop in performance or lack of power. This can be caused by a number of factors, such as a malfunctioning motor or blocked internal components. Regular cleaning and inspection are essential to ensure smooth operation. In some cases, replacing a damaged motor or cleaning air filters might resolve the issue.

Leaks and Pressure Irregularities

Another common problem is air leaks or pressure fluctuations, which can affect the tool’s efficiency. Leaks may occur in various places, such as valves or seals, leading to inconsistent performance. To address this issue, carefully check all connections and seals for damage. Replacing worn-out gaskets or tightening loose connections can often restore proper function.