When it comes to maintaining outdoor equipment, knowing the individual components and their functions is essential for proper care and efficient performance. A thorough understanding of each element can help prevent issues, save time, and ensure your tool runs smoothly for longer periods. This guide will provide an in-depth look at how to identify key parts, their roles, and how to interpret detailed illustrations of your equipment’s structure.

Being familiar with the internal structure allows you to spot wear and tear or damage early, facilitating timely repairs and replacements. Whether you are a professional or a hobbyist, having this knowledge can make maintenance tasks easier and more effective. Additionally, understanding how each part interacts with others enhances your ability to troubleshoot common issues that may arise during use.

Effective repair and upkeep require not only the right tools but also the insight into how each component contributes to the overall functionality. In the following sections, we’ll explore how to read and interpret detailed schematics, helping you make informed decisions when maintaining or fixing your blower.

Understanding the Blower Components

To maintain any outdoor power tool effectively, it is crucial to understand the individual elements that make up its structure. Each component plays a specific role in the overall performance, and recognizing how they work together can greatly simplify repairs and regular maintenance. A comprehensive knowledge of these parts not only helps in troubleshooting but also ensures the equipment functions optimally over time.

The Key Components and Their Roles

Every machine is made up of various systems, such as the engine, fuel system, and air intake. Understanding how these work together can make diagnosing problems easier. For example, the engine is the powerhouse that drives the tool, while the air intake and exhaust system ensure that the motor receives the necessary airflow to operate efficiently. Regular checks of these elements can help prevent breakdowns and extend the lifespan of the equipment.

Identifying Signs of Wear and Damage

Identifying signs of wear early can save you both time and money in the long run. Common issues like clogged filters, damaged seals, or loose connections can drastically reduce performance. By becoming familiar with how each component is supposed to look and function, you can quickly spot irregularities and take action before they lead to more serious damage. Regular inspections and maintenance are key to keeping your blower in top condition.

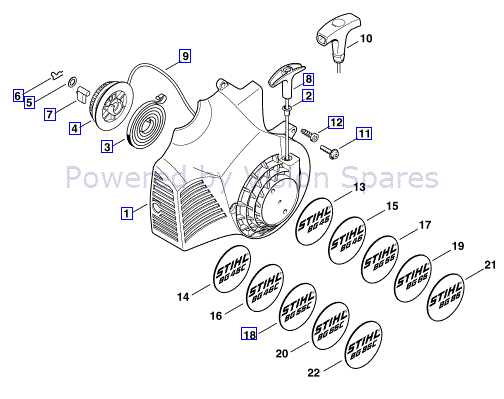

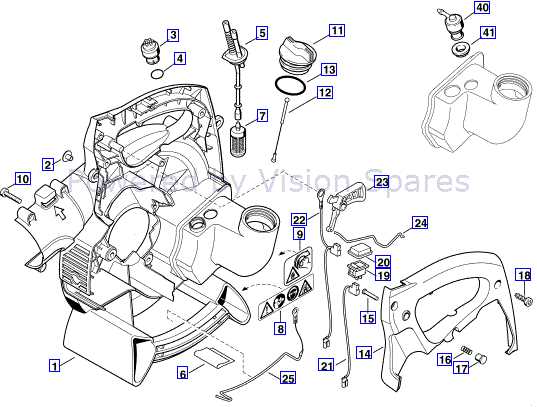

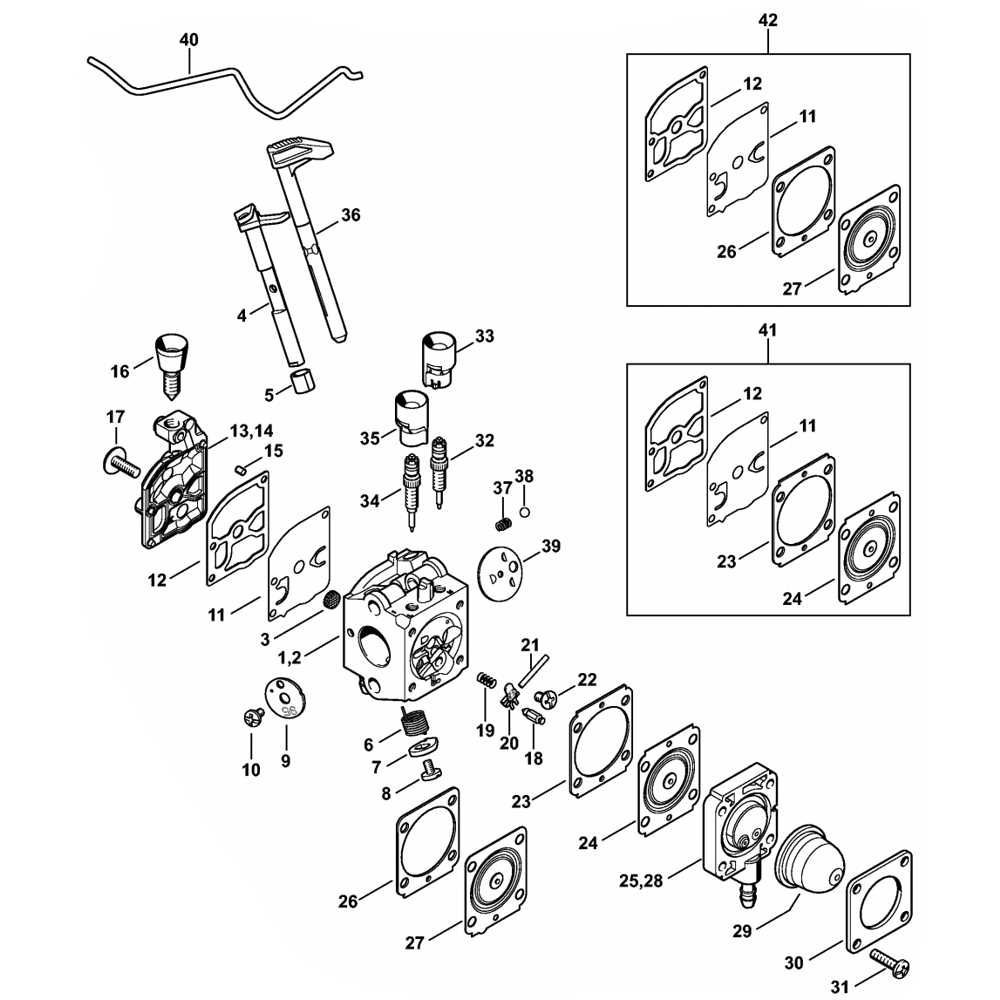

How to Read the Equipment Schematic

Interpreting a schematic for your tool can initially seem complex, but with a bit of practice, it becomes an invaluable resource for maintenance and repairs. A schematic serves as a visual map of the equipment, showing how each individual component fits into the whole structure. Understanding how to read this map is essential for identifying the correct parts, their functions, and how to assemble or disassemble them properly.

Understanding the Layout

The schematic will typically be divided into sections that represent different parts of the tool, such as the motor, fuel system, and airflow components. Each section will include labeled components with corresponding numbers or letters, allowing you to easily locate and identify specific pieces. Pay close attention to the lines connecting these elements, as they often represent mechanical links or pathways, such as hoses or wires, that enable the components to work together efficiently.

Using the Numbers and Symbols

Numbers and symbols are key to understanding the schematic. Each component will be marked with a number, which corresponds to a part listed in the parts manual. These numbers make it easy to find replacement components or accessories. Additionally, symbols may be used to represent actions such as fuel flow or air circulation, further clarifying the role of each part. Familiarizing yourself with these symbols and their meanings will help you interpret the schematic quickly and accurately.

Common Parts and Their Functions

Understanding the key components of your tool and how they contribute to its operation is essential for maintaining optimal performance. Every machine is made up of several important elements, each with its specific purpose. In this section, we will discuss the most common components found in many outdoor power tools and their roles in ensuring smooth and efficient operation.

- Engine – The engine is the core of the machine, providing the necessary power to drive all other functions. It converts fuel into mechanical energy that drives the fan or motor, enabling the equipment to perform its tasks.

- Fuel Tank – The fuel tank stores the fuel required to operate the engine. It is crucial to ensure the fuel system is clean and the tank is properly sealed to avoid leaks and ensure efficient fuel consumption.

- Air Filter – The air filter prevents dust and debris from entering the engine, ensuring that only clean air reaches the combustion chamber. A clogged filter can reduce engine performance and fuel efficiency.

- Ignition System – The ignition system is responsible for starting the engine. It includes components like the spark plug and coil, which work together to generate the spark that ignites the fuel mixture in the engine.

- Exhaust System – The exhaust system directs gases out of the engine, helping to prevent overheating and ensuring that harmful emissions are safely expelled from the tool.

Each of these components plays a vital role in keeping the equipment running smoothly. Regular inspection and maintenance of these elements can help prevent damage and improve the overall longevity of your tool.