Understanding the structure of your lawn equipment is essential for efficient maintenance and long-lasting performance. Having a clear view of each component and its placement ensures smooth operation and easy troubleshooting when problems arise.

In this section, we explore how knowing the key elements of your mower can help you identify potential issues and choose the correct replacement parts. A well-maintained machine performs better and saves you time and effort in the long run.

Proper maintenance is the backbone of keeping your equipment in top shape. Regular inspection of all key sections allows you to spot wear and tear early, preventing costly repairs. Understanding the layout of your mower can make this process significantly easier and more efficient.

Understanding the Bolens BL160 Components

When maintaining any lawn equipment, it’s crucial to have a clear understanding of its various elements. Each part plays a significant role in ensuring optimal functionality, and knowing how they interact can help in identifying issues and improving performance.

In this section, we break down the essential components of your machine. From the engine to the cutting mechanism, each section is designed to work together, and understanding their function is key to effective upkeep. Regular inspection of these elements can help prevent unexpected breakdowns and ensure smooth operation.

Knowing your machine’s setup gives you the advantage of easily locating any worn-out or damaged parts. The engine, transmission, and other vital components must be checked periodically for signs of wear. Familiarizing yourself with their arrangement can save time during maintenance and repairs.

How to Use the Parts Diagram Effectively

Using a schematic of your machine’s components can significantly improve your maintenance process. This visual guide allows you to identify each part and its specific location, making troubleshooting and repairs much easier.

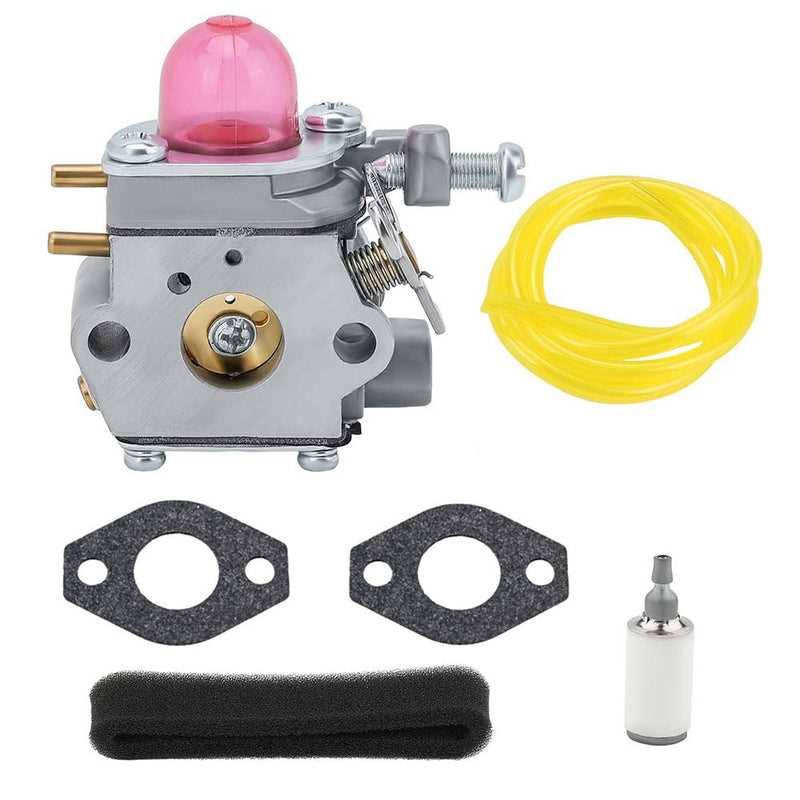

Identifying Key Components

The first step in using the visual guide is to familiarize yourself with the major sections of the equipment. Focus on understanding how different parts are connected and how they contribute to the overall function. Knowing each part’s role can help you spot issues faster and choose the right replacement parts.

Locating Specific Issues

When problems arise, refer to the schematic to pinpoint the exact location of the malfunctioning components. A clear, detailed reference allows you to tackle specific areas, minimizing the risk of missing important details during inspection or repairs.

Common Issues and Parts Replacements

Every machine experiences wear and tear over time, and being aware of common issues can help you prevent breakdowns and extend its lifespan. Regular inspection of key components ensures that problems are detected early, minimizing the need for major repairs.

Some of the most frequent issues include engine malfunctions, faulty belts, and worn-out blades. Understanding which components are prone to damage allows you to take proactive measures, such as replacing damaged parts before they cause further complications. Regular maintenance can also help prevent dirt and debris from affecting critical areas, improving overall performance.