Understanding the intricate structure of equipment is essential for efficient repair and upkeep. Having a clear view of each component and its function ensures better handling and prolongs the lifespan of machinery. Whether you’re working with an older model or a newer one, identifying the correct parts and knowing how they fit together is crucial for smooth operations.

Detailed visual representations play a key role in identifying individual components. They simplify complex assemblies and provide clarity on how everything works in unison. With proper guidance, even those with limited technical knowledge can perform repairs confidently and effectively.

Regular inspection and maintenance are vital in preventing major breakdowns. Understanding how each piece fits into the larger system allows for quicker troubleshooting and helps ensure that each part performs optimally. Knowing what to look for can make the difference between minor fixes and costly replacements.

Understanding the Components of the Equipment

When working with complex machinery, it is essential to have a clear understanding of its individual components. Each element plays a specific role, contributing to the overall performance and functionality. A comprehensive knowledge of these pieces allows for smoother maintenance and more efficient repairs. Recognizing each part’s purpose and interconnection can significantly improve troubleshooting skills and ensure optimal operation.

The Importance of Component Identification

Accurate identification of every component within the system is key to successful maintenance. Knowing what each part looks like and where it is positioned helps avoid confusion during repairs. It also enables more informed decisions when replacing or upgrading individual elements. In many cases, understanding the precise location and function of a component can save time and prevent errors.

Common Features and Variations

While many components share similar characteristics, subtle differences in design or function can impact performance. Some parts may have specialized features that cater to specific tasks, while others serve more general functions. Being able to distinguish between these variations is crucial for ensuring that the right component is used in the right context, helping to maintain the equipment’s efficiency and longevity.

How to Read the Equipment Layout

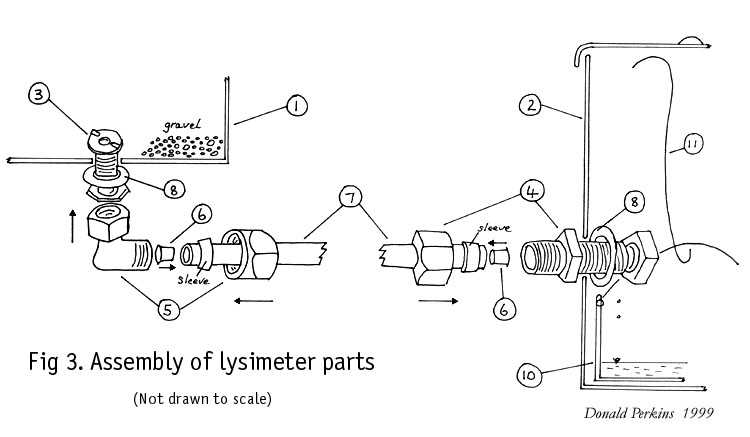

Understanding the layout of a mechanical system is essential for effective maintenance and repair. The visual guide provides a detailed overview of how various components are arranged and connected. By interpreting these visuals correctly, you can quickly identify individual parts, their positions, and their relationships to other elements. This skill is invaluable for performing repairs accurately and efficiently.

To begin, focus on the labels associated with each element. These identifiers often indicate the specific function or model number, helping you match components with those listed in manuals or available for replacement. Pay attention to any arrows or lines that represent connections between parts, as these indicate the flow of energy or data and show how different sections interact.

Additionally, observe the grouping of similar parts. Often, components that perform related functions are grouped together, which helps streamline the repair process. Recognizing these clusters can reduce the time spent searching for individual pieces and assist in diagnosing issues within specific sections of the system.

Common Components and Maintenance Tips

Proper maintenance of machinery relies heavily on understanding the common components that require regular attention. Some elements, due to their function, are more susceptible to wear and tear and need frequent inspection. Regular upkeep ensures that the system runs smoothly and extends its overall lifespan. Familiarizing yourself with these critical parts and knowing how to care for them can prevent major failures and costly repairs.

Essential Components to Monitor

One of the most frequently checked components in most machines are the moving parts. These can include gears, bearings, and belts. Over time, friction and regular use cause these pieces to degrade, which can affect performance. Regular lubrication and occasional replacement are essential to avoid breakdowns. Additionally, electrical components such as switches and wires should be checked for any signs of damage or wear.

Maintenance Strategies for Longevity

Establishing a consistent maintenance routine is the best way to prolong the life of your equipment. Clean and inspect each part regularly to ensure they are functioning properly. For moving parts, use the appropriate lubricants and check for signs of damage, such as cracking or excessive wear. Ensure all electrical connections are secure and free from corrosion to avoid potential malfunctions. Following these simple steps will help maintain optimal performance and minimize downtime.