Understanding the structure of an engine and its individual elements is essential for anyone involved in machinery maintenance. A comprehensive overview of these components provides valuable insights into their functions and how they work together to ensure optimal performance.

Exploring the connections between various mechanical parts allows for better troubleshooting and smoother repairs. Knowing the roles of key pieces within the system can help identify issues early and streamline the repair process.

Proper maintenance begins with knowing the intricate details of each part’s design and placement. This knowledge allows for effective diagnosis and targeted actions that improve the longevity of the equipment and reduce downtime.

Understanding the Engine’s Inner Workings

Engines are complex systems, where every component plays a vital role in ensuring smooth operation. Understanding the inner mechanics of such a system is crucial for anyone involved in the maintenance or repair of heavy machinery.

Each section of the engine is designed with a specific function that contributes to the overall performance. From the fuel system to the exhaust components, all parts work together to optimize power output and efficiency.

By studying the arrangement and interaction of these key elements, one can better diagnose issues and make informed decisions during repairs. Familiarity with the engine’s structure not only aids in troubleshooting but also enhances long-term reliability and performance.

Key Components of Engine System

To fully grasp the workings of an engine, it’s essential to understand the key elements that contribute to its performance. These components interact with each other, each having a distinct role in ensuring the system runs smoothly and efficiently. Familiarity with these components allows for effective diagnosis and maintenance.

Fuel and Air Systems

The fuel and air systems are at the heart of an engine’s power generation. The fuel system delivers the necessary fuel to the combustion chamber, while the air system ensures that sufficient oxygen is available for combustion. Both systems must be in perfect harmony to ensure optimal engine efficiency and performance.

Lubrication and Cooling Systems

The lubrication system plays a crucial role in reducing friction between moving parts, ensuring smooth operation. Meanwhile, the cooling system prevents the engine from overheating by dissipating excess heat. Both systems are indispensable for maintaining engine longevity and preventing breakdowns during extended use.

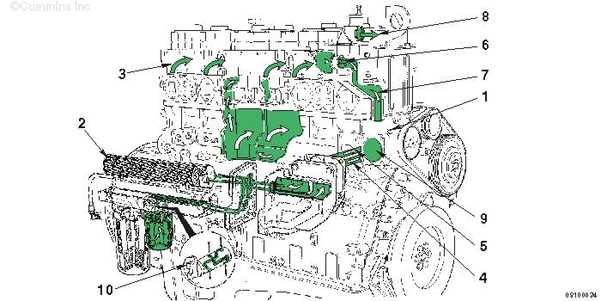

How to Read the Component Layout

Understanding how to interpret the layout of an engine’s components is essential for effective maintenance and repair. These visual representations provide detailed insights into the arrangement and function of each part within the system. Knowing how to read these layouts can greatly aid in identifying specific components and understanding their roles.

Each section of the layout is typically labeled with unique identifiers that correspond to individual components. Familiarizing yourself with these labels helps pinpoint the exact part in question, whether you’re performing a repair, replacement, or routine inspection.

Pay attention to the connections between components as well, as these relationships indicate how the parts interact during operation. This knowledge is vital for diagnosing issues and ensuring the system remains functional over time.