In every vehicle, the system that connects the wheels to the engine plays a critical role in ensuring smooth movement and overall performance. A well-functioning drive mechanism is essential for transmitting power from the engine to the wheels, allowing for efficient acceleration, stability, and handling.

To grasp how this complex system works, it’s important to understand the individual elements that come together to form the driving structure. Each component has a specific function, and when combined, they enable the vehicle to perform at its best. The parts that make up this system are integral to vehicle maintenance and repair, highlighting the need for accurate knowledge about their structure and functionality.

Proper maintenance of these elements ensures durability and reduces the risk of failure, which can lead to costly repairs and potential safety hazards. By understanding how these parts work together, vehicle owners can make more informed decisions when it comes to repairs and maintenance.

Understanding the Key Components of the Drive System

The drive mechanism of a vehicle is made up of several interconnected elements that work together to transfer power from the engine to the wheels. These components are essential for motion, stability, and overall vehicle efficiency. Each part contributes to the functioning of the vehicle, and when maintained properly, ensures reliable performance over time.

Main Drive Shaft

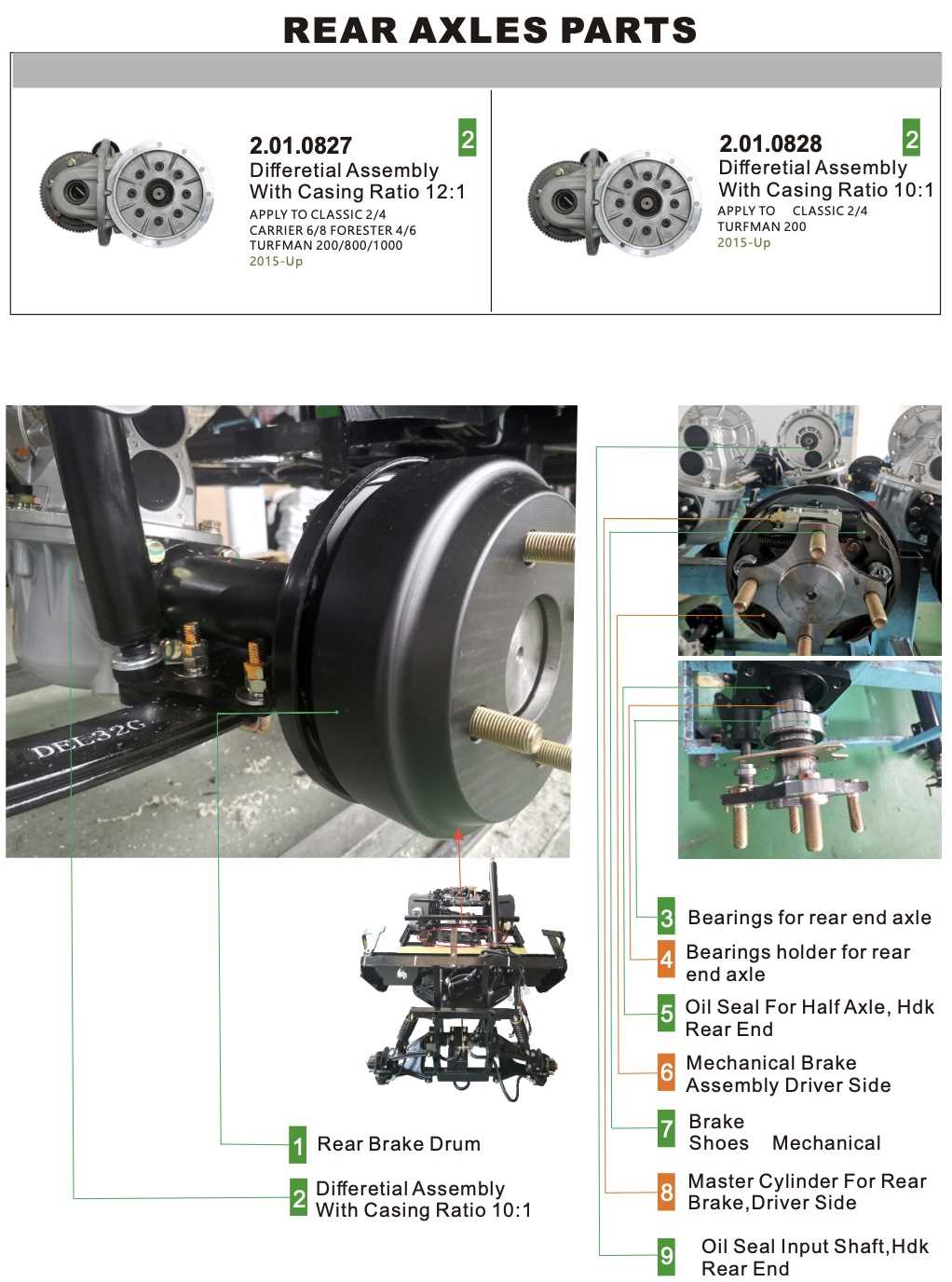

The main shaft is a crucial component responsible for transmitting rotational power from the engine to the wheels. It acts as the central link in the drive structure, converting engine energy into motion. The strength and durability of this shaft are vital for smooth operation, as any issues here can significantly affect the vehicle’s performance.

Supporting Bearings and Housing

Bearings and housings support the rotating elements within the drive system. They provide stability and reduce friction, ensuring that the parts move smoothly. These components must be well-maintained to avoid excessive wear, which can lead to more serious mechanical failures.

Regular inspection of the drive components is necessary to identify signs of damage or wear before they lead to significant issues. Replacing worn-out elements in a timely manner can prevent costly repairs and maintain the vehicle’s overall performance.

How Drive Components Impact Vehicle Performance

The system that connects the wheels to the rest of the vehicle is essential for smooth operation and stability. It plays a vital role in transferring the engine’s power to the wheels, allowing the vehicle to move efficiently. This mechanism affects various aspects of performance, including acceleration, handling, and overall driving experience.

One of the primary ways this system influences performance is through its ability to distribute torque evenly. A well-balanced setup ensures that power is delivered effectively, minimizing wheel slippage and improving traction, especially under challenging driving conditions. Proper alignment and functioning of these components can lead to smoother acceleration and better control over the vehicle.

Additionally, the condition of these elements directly impacts the vehicle’s ability to handle weight distribution. A failure or imbalance in the system can result in uneven load transfer, which may lead to poor handling and an increased risk of accidents. Regular maintenance of the drive components is key to ensuring that the vehicle operates safely and efficiently over time.

Common Issues with Drive System Components

The system responsible for transmitting power from the engine to the wheels is critical for the proper functioning of any vehicle. Over time, wear and tear can lead to a variety of issues that affect performance and safety. Understanding the common problems that arise in this system helps in identifying and addressing them before they cause significant damage.

Worn-Out Bearings

One of the most common issues is the deterioration of bearings that support the rotating elements. When bearings wear out, they can cause noise, vibrations, and eventually lead to failure. These problems can significantly reduce the efficiency of the system and impact vehicle stability, especially during acceleration or turning.

Damaged Seals and Leaks

Another issue that often arises is the failure of seals, which can lead to fluid leaks. When seals break down, lubrication within the system can escape, causing parts to overheat and wear more rapidly. This not only reduces the lifespan of the components but can also result in costly repairs if left unchecked.

Regular inspection and timely replacement of worn components are essential for maintaining the overall health of the drive system. Keeping these parts in good condition ensures that the vehicle operates smoothly and prevents unexpected breakdowns.