Maintaining heavy equipment and machinery requires attention to detail, especially when dealing with complex systems. To ensure smooth operation and avoid costly breakdowns, having a clear understanding of the components involved is crucial. Proper identification and replacement of specific parts can significantly reduce downtime and improve overall functionality.

When tackling repairs, a visual reference can make the process more straightforward. Such references not only help locate the correct parts but also provide insight into their roles within the system. This visual aid can guide technicians through the steps necessary to keep equipment running at its best.

By using well-organized diagrams, identifying wear and tear becomes easier, allowing for precise interventions. Knowing which parts need attention ensures that maintenance is performed in the most efficient manner, ultimately extending the life of the machinery and improving its performance.

Understanding Components for Maintenance

How to Read the Visual Guide Correctly

Effective maintenance requires a clear understanding of the different elements within a system and how they interact. Knowing how to identify and work with each component allows for timely repairs and ensures equipment operates efficiently. A well-organized reference guide is key for professionals to pinpoint exactly what needs attention, streamlining the repair process and reducing the chance of mistakes.

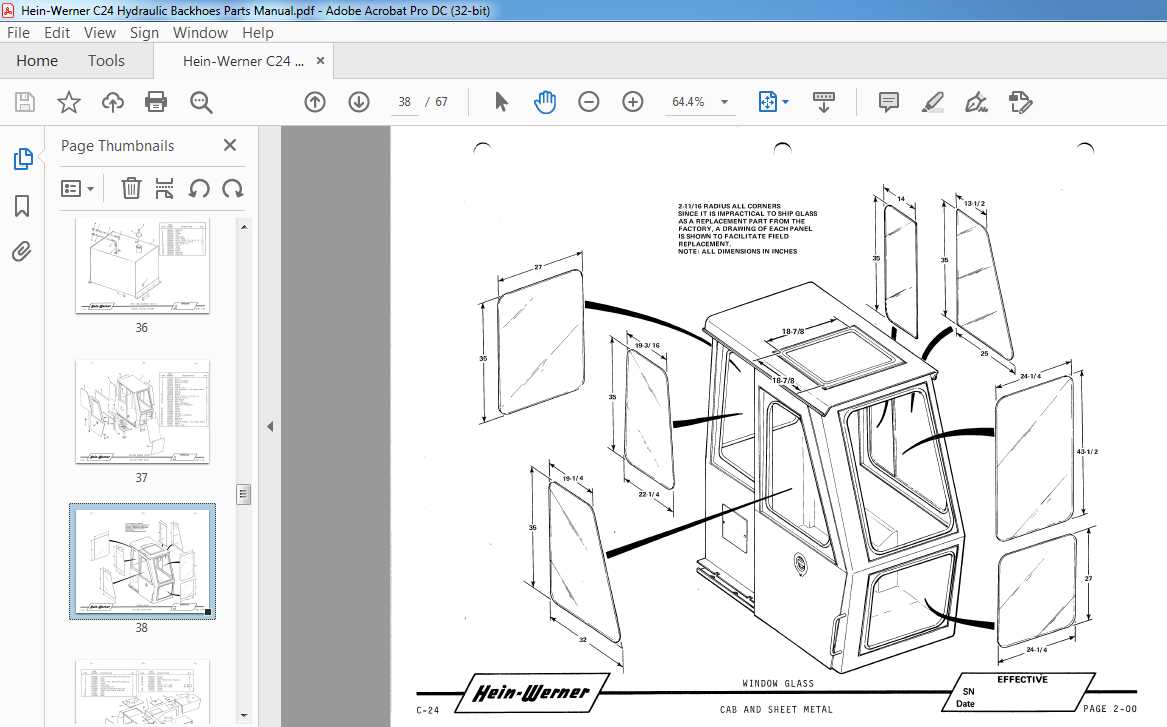

To read a visual guide accurately, it’s important to familiarize yourself with the layout and structure of the representation. The illustrations are typically broken down into distinct sections, each highlighting specific components and their relationship to the entire system. Understanding how to interpret these symbols and labels will make it easier to identify what part is malfunctioning or requires replacement.

By approaching the guide systematically, technicians can work step by step through the machinery. Whether identifying a worn-out component or performing routine checks, a well-read guide not only saves time but also ensures that every repair is performed with precision, improving the overall reliability and lifespan of the equipment.

Common Components and Their Functions

Identifying and Replacing Key Elements

Understanding the key components of any system is essential for maintaining its functionality. Each part plays a specific role, and recognizing when one of these elements is malfunctioning allows for targeted repairs. Familiarity with the most common components can make troubleshooting faster and more accurate, minimizing downtime and improving overall efficiency.

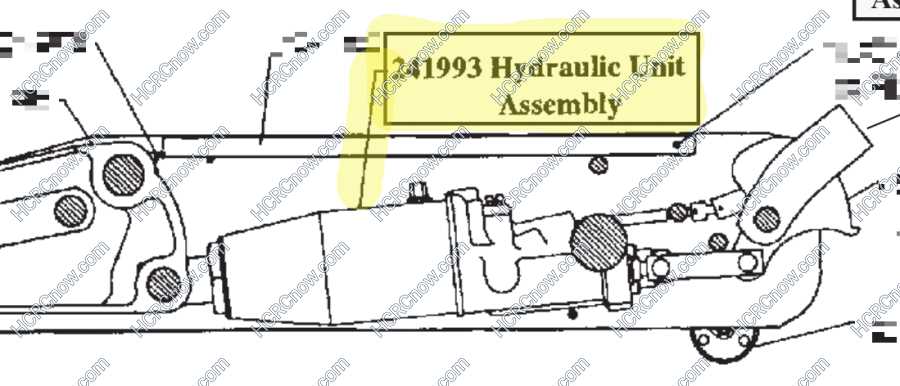

Some of the most important elements in machinery are those that handle pressure, movement, and stabilization. These include hydraulic pumps, actuators, and control valves. Each of these plays a vital role in maintaining the proper operation of the system, ensuring smooth and reliable performance. Knowing how to identify wear or malfunction in these critical components is crucial for effective repairs.

When it’s time to replace a faulty element, accurate identification ensures that the right replacement is chosen. A detailed guide will provide valuable information on where each component is located and how it integrates with the entire mechanism. By following the correct procedures, technicians can efficiently remove and install the new part, ensuring the system operates as intended.

Advantages of Precise Parts Identification

Accurate identification of individual components within any system is essential for effective maintenance and repair. The ability to quickly and correctly pinpoint the issue allows technicians to address problems without unnecessary delays. Whether it’s a simple replacement or a complex fix, knowing exactly which part needs attention can save both time and resources.

Improved Repair Efficiency

With clear identification, technicians can focus their efforts on the correct area, avoiding unnecessary disassembly of unrelated parts. This not only reduces repair time but also ensures that other components are not disturbed during the process, preventing further complications. Faster repairs lead to less downtime and better productivity overall.

Cost Savings and Longer Equipment Lifespan

Precise identification helps in selecting the correct replacement items, preventing costly errors such as ordering the wrong components. It also reduces the chances of repeated repairs due to incorrect installations. Proper maintenance extends the life of the system, resulting in long-term cost savings and optimal performance.