Understanding the individual elements of a water or fluid circulation system is essential for proper maintenance and efficient operation. Knowing how each component functions and interacts with the others can prevent costly repairs and ensure long-term performance.

With a clear visual reference and breakdown of the system’s structure, identifying issues becomes much easier. This approach allows users to quickly spot potential problems and address them without unnecessary delays or confusion.

By following a structured guide, even those with minimal experience can learn to troubleshoot, repair, and maintain their equipment confidently. This comprehensive resource will help you gain a deeper insight into the machinery, enabling smoother operation and extending the life of your system.

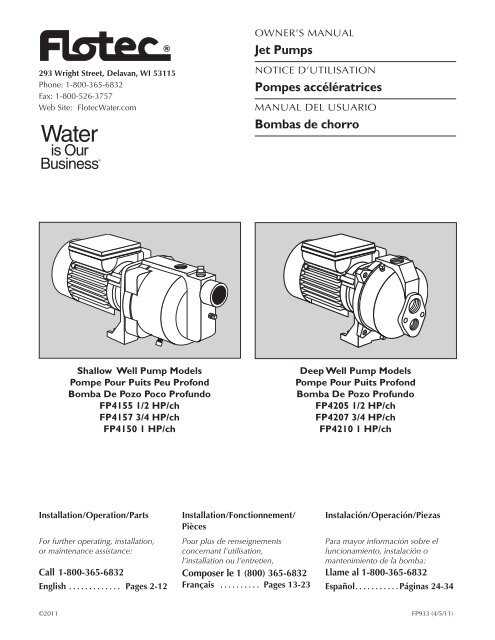

Understanding the Flotec Pump Components

To effectively maintain and repair any fluid-moving system, it’s crucial to understand how each element contributes to the overall function. Each component plays a specific role, whether it’s regulating flow, ensuring pressure, or controlling the movement of water or other liquids through the system.

By familiarizing yourself with the different elements, you can identify signs of wear, troubleshoot issues, and ensure that the system operates at peak efficiency. A clear understanding of these components allows you to address minor problems before they become major, reducing downtime and extending the system’s lifespan.

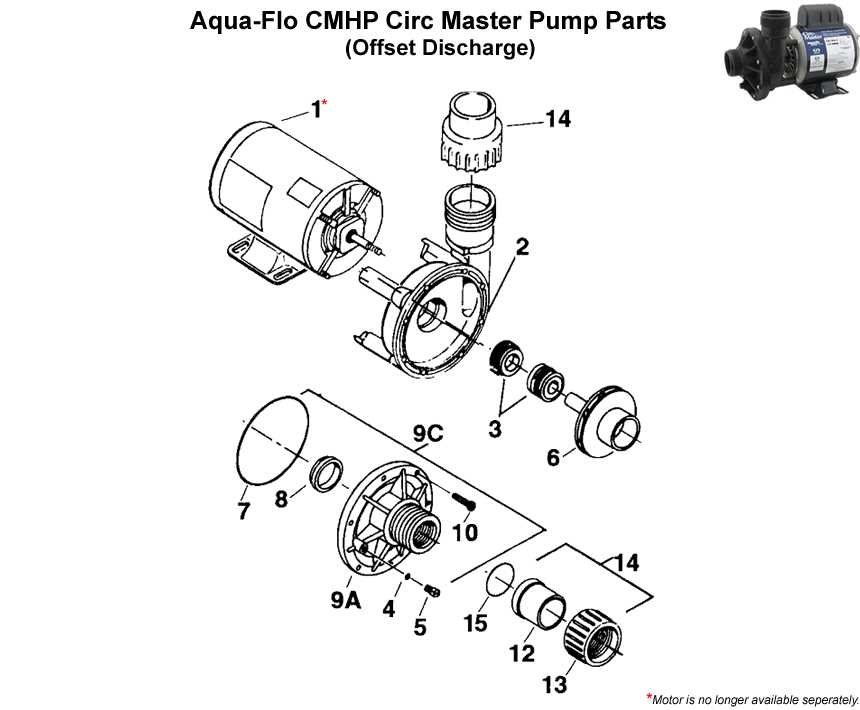

Visual aids and detailed breakdowns can be incredibly helpful in grasping how all these parts are connected. This knowledge empowers you to make informed decisions, whether you’re performing regular maintenance or addressing unexpected malfunctions.

How to Identify Flotec Pump Parts

Identifying the various components of a fluid circulation system is essential for troubleshooting and repairs. Recognizing each element’s function and its appearance allows you to address issues quickly and avoid unnecessary replacement of parts.

Examine the Main Components

The primary elements to focus on are typically the motor, housing, seals, and internal mechanisms that control the movement of liquids. Each part is uniquely designed and often comes with specific markings or labels that make identification easier. Take note of these details as they are crucial when searching for replacements or making adjustments.

Use Visual References and Documentation

Incorporating visual guides, such as exploded views or detailed charts, can significantly simplify the identification process. These resources clearly show how the components fit together, helping you understand the layout and the role of each part in the overall system.

Repairing Your Flotec Pump with Diagrams

When facing a malfunction, having a clear reference to guide you through the repair process is invaluable. Detailed illustrations of the system’s layout allow you to pinpoint the exact issue and understand how the components interact, simplifying the repair process.

Step-by-Step Guide to Troubleshooting

Using a visual breakdown helps you identify specific elements that may be causing problems. Start by comparing the actual setup with the reference images to locate the malfunctioning area. This approach ensures you focus on the correct parts, minimizing guesswork.

Effective Repairs with Clear Visuals

Once the issue is identified, a diagram can show how to disassemble, replace, or repair the necessary components. These guides often include helpful tips, such as proper alignment, lubrication, and torque specifications, which are crucial for ensuring a successful fix and preventing further issues.