Every appliance contains several essential elements that work together to ensure its proper function. Knowing how each part contributes to the overall operation is crucial for troubleshooting and maintenance. A clear understanding of these components can save time, effort, and money by helping you identify and address issues early.

When facing malfunctions or attempting repairs, having a visual guide can make a significant difference. Knowing the role of each component can provide insights into potential problems, allowing for more accurate diagnosis. By familiarizing yourself with the structure and functions of these key elements, you can ensure smooth operation and prolong the life of your device.

Identifying the necessary components and understanding their relationship can be overwhelming at first, but breaking it down into manageable parts helps simplify the process. The correct approach allows you to confidently identify problems and, when needed, find suitable replacements or repairs without confusion.

Understanding Ice Maker Components

In any device designed to produce frozen cubes or similar substances, several key elements work in harmony to ensure smooth functionality. Each component plays a specific role in maintaining the process, from water intake to freezing. Familiarizing yourself with these critical sections can help you understand how to troubleshoot issues or identify potential failures.

Key Functional Elements

The functionality of any freezing appliance depends on a set of components responsible for water conversion into solid form. These include sensors, valves, and motors that control water flow and freezing cycles. Understanding the interactions between these elements allows you to recognize potential disruptions in the freezing process and their causes.

Role of Control Mechanisms

Control mechanisms are essential in regulating the entire cycle. These can range from thermostats that monitor temperature to switches that trigger freezing or defrosting actions. A malfunction in any of these areas can lead to inefficient freezing or failure to produce the desired outcome. Proper knowledge of their location and operation ensures quicker repairs and minimal downtime.

How to Identify Essential Components

When dealing with any malfunctioning unit, identifying the correct elements for repair or replacement is crucial. Recognizing the different sections within the system allows you to approach the problem methodically and efficiently. This can prevent unnecessary purchases and ensure the correct issue is addressed swiftly.

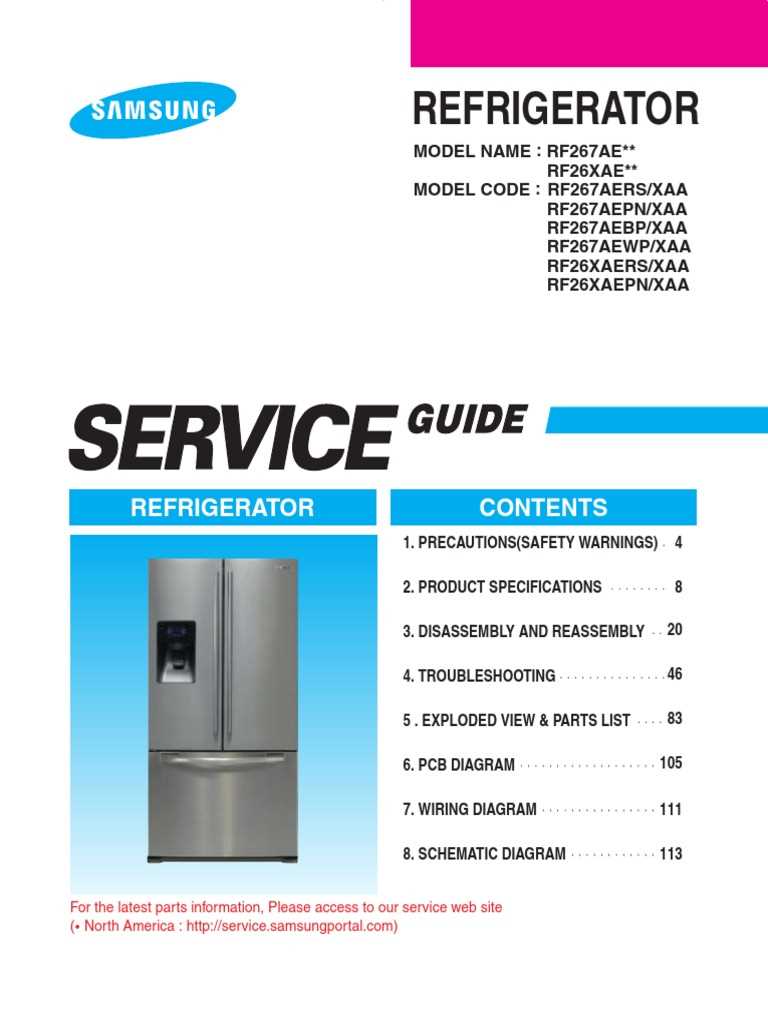

Start with the model number of your appliance. Each model has specific identifiers for its internal components, often listed in the product manual or on the device itself. These numbers can guide you in finding the exact replacements needed.

Labeling and categorizing parts according to their function is another helpful step. Many components are designed to work together, so understanding their role in the system will allow you to differentiate between similar-looking but functionally different pieces. Consult product guides, online resources, or customer service for accurate identification.

Common Issues with Ice Makers

When dealing with a malfunctioning freezing unit, several typical problems can arise. These issues often involve improper temperature regulation, water flow disruptions, or faulty sensors that prevent the system from functioning as intended. Understanding these common complications can help pinpoint the root cause and expedite repairs.

Temperature fluctuations are one of the most frequent concerns. If the appliance fails to maintain a consistent cold level, it can lead to incomplete freezing or excess water accumulation. This issue often points to problems with the thermostat or temperature control mechanisms.

Water supply interruptions are another common issue. If the system is not receiving adequate water, it cannot produce the desired frozen product. This could be due to a clogged water line, malfunctioning valve, or damaged pump, all of which hinder the flow necessary for the freezing process.