Understanding the key elements that enable efficient stopping power is crucial for vehicle safety and performance. These components play a significant role in ensuring smooth and responsive deceleration, contributing to overall driving comfort and security.

Every mechanism within the assembly serves a unique purpose, working in harmony to maximize reliability. From the initial force application to the eventual dissipation of energy, each part is meticulously designed for precision and durability.

Recognizing the function of each element can help maintain and troubleshoot the system, ensuring that any potential issues are detected early. Proper care and attention to these components will prevent wear and ensure optimal functionality for years to come.

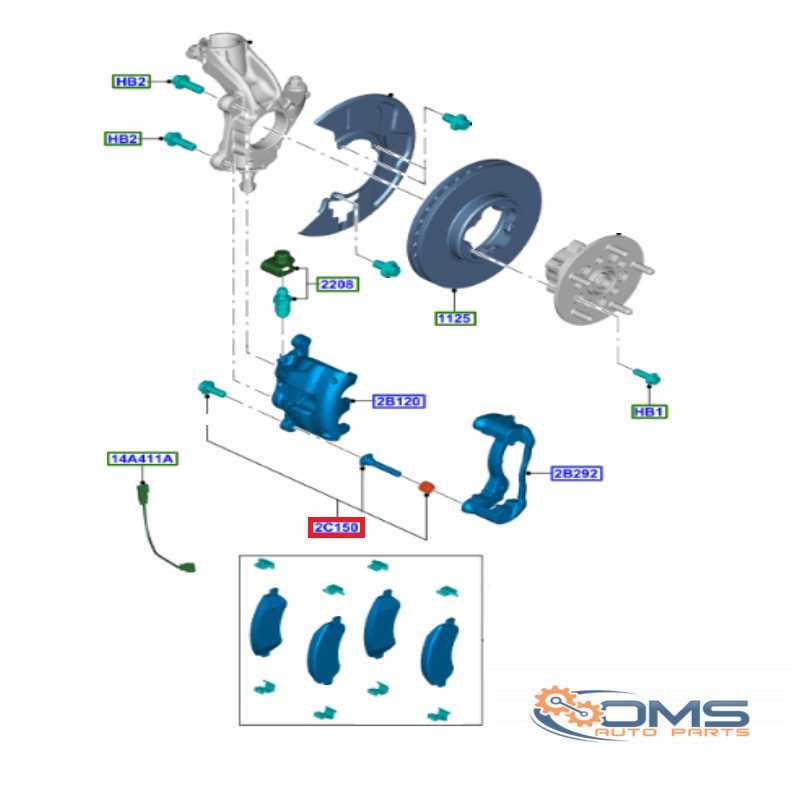

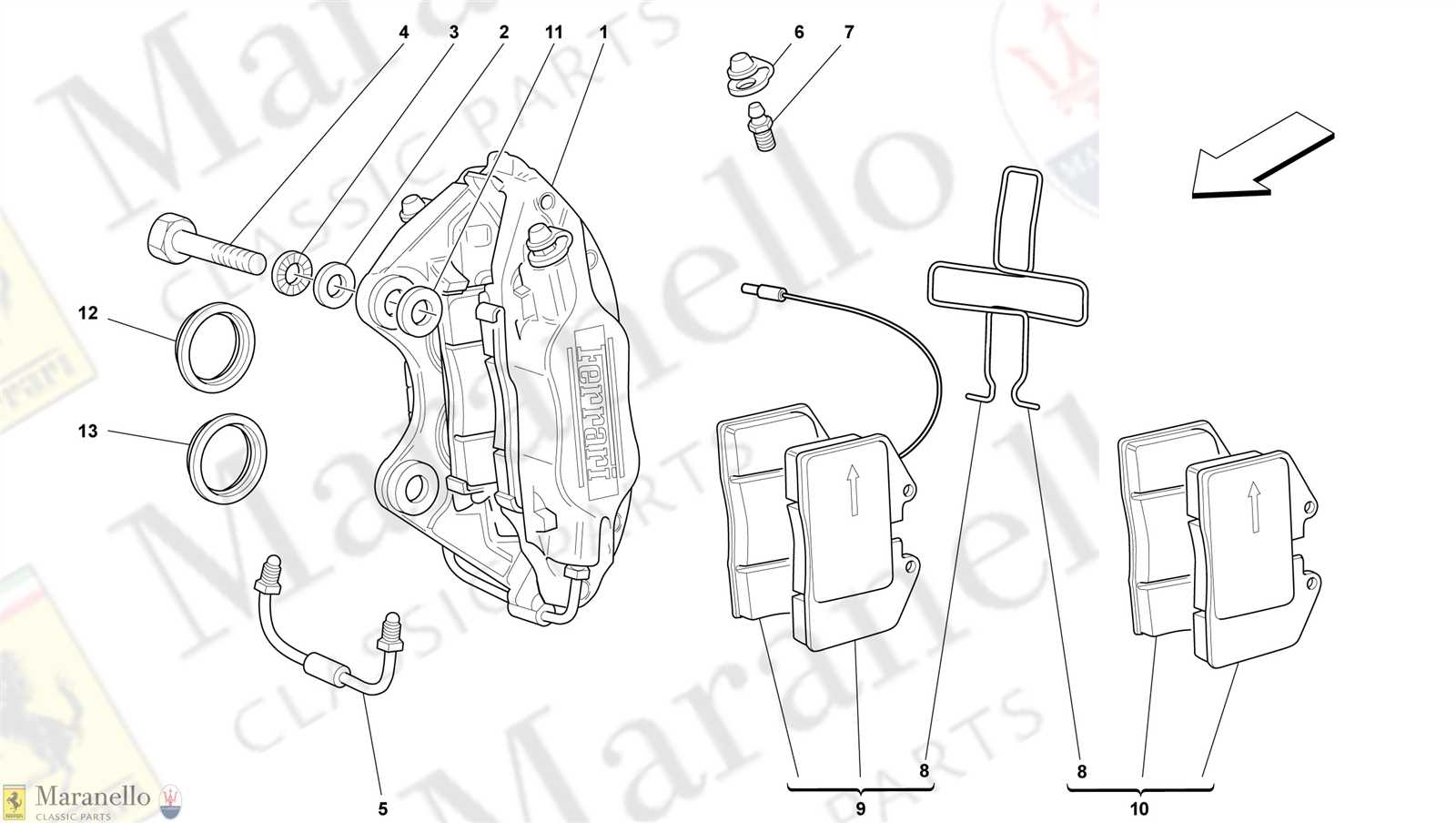

Understanding the Components of Brake Calipers

The elements that facilitate effective stopping mechanisms in vehicles are composed of several intricate components working together. These components are responsible for transferring force, applying pressure, and ensuring controlled deceleration, all of which are vital for optimal vehicle performance and safety.

The Role of Pistons and Housing

One of the core elements in the assembly is the piston, which exerts pressure on the friction material when activated. This action helps to generate the necessary force for slowing down the vehicle. The housing encases the piston and provides a durable structure to withstand high temperatures and stress during operation.

Seals and Mounting Brackets

Seals are essential for preventing fluid leakage and ensuring the system remains fully operational. These components help maintain the internal pressure and protect other sensitive parts from external contaminants. Meanwhile, mounting brackets are crucial for securing the entire structure in place, providing stability during operation.

How Brake Calipers Contribute to Vehicle Safety

The ability to stop a vehicle effectively and quickly is a crucial aspect of road safety. Various mechanisms within the stopping system play a key role in controlling deceleration, ensuring that drivers can respond to changing road conditions or emergencies without risk. Properly functioning components ensure smooth and reliable performance in all driving conditions.

Precise Force Application for Optimal Stopping Power

By exerting controlled force on the friction elements, these components help generate the necessary resistance to slow down or stop the vehicle. This precise application of pressure ensures that the vehicle can stop quickly when needed, minimizing the risk of accidents caused by delayed reactions.

Enhanced Control and Stability During Stopping

When engaged, the entire assembly contributes to maintaining vehicle stability by distributing pressure evenly across the braking surface. This balanced approach prevents wheel lockup or uneven braking, ensuring a safe and controlled stop, particularly in emergency situations or on slippery surfaces.

Identifying Wear and Tear in Brake Calipers

Over time, the continuous use of the stopping system can lead to wear on several components. It is important to detect early signs of damage or deterioration to maintain vehicle safety and ensure optimal performance. Identifying these issues can help prevent costly repairs and improve reliability.

Common Signs of Damage

- Increased noise while applying force, such as squealing or grinding sounds

- Visible cracks or wear marks on the friction surfaces

- Uneven pad wear, which may indicate misalignment or improper pressure distribution

- Unresponsive or sluggish pedal feel when applying force

Inspection and Maintenance Tips

Regular checks and maintenance of key components help identify potential issues before they become critical. Key inspection points include:

- Check for fluid leaks around the assembly

- Inspect seals and gaskets for any signs of wear or cracking

- Ensure proper alignment of the friction elements and housing

- Monitor for any unusual vibrations or noises during operation