Engines are complex machines made up of numerous components working in harmony to provide power and efficiency. Knowing the structure and function of each element is essential for maintenance and troubleshooting. A clear understanding of how the various parts are arranged and interact with each other can significantly improve the performance and longevity of the engine.

In this section, we will explore the layout of a specific engine model, highlighting its key components. By studying its configuration, you can better grasp how each part contributes to the overall functioning and how to identify potential issues for more effective repairs.

Exploring the internal workings of this machine allows you to make informed decisions about care, servicing, and upgrades. Whether you’re a technician or an enthusiast, this detailed overview will provide valuable insights into maintaining peak engine performance.

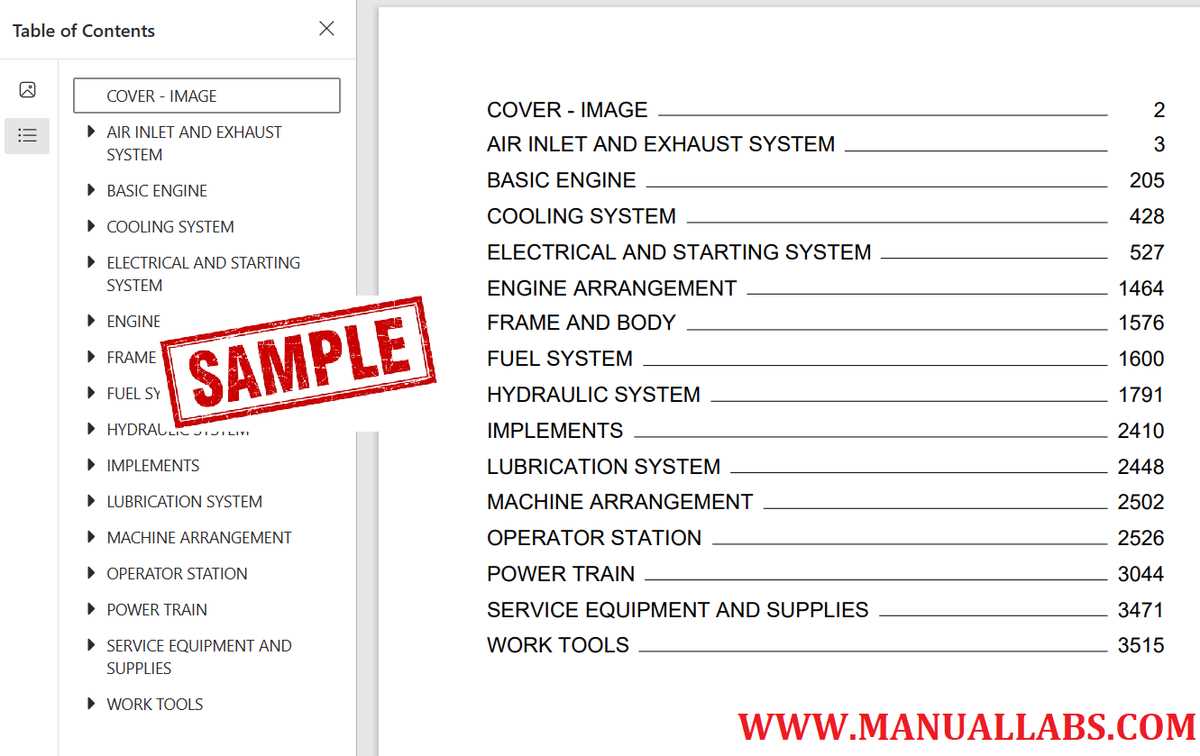

Understanding the Engine Layout

An engine layout refers to the organization of its various components, including the block, cylinders, and supporting systems. Understanding how these parts are arranged is crucial for identifying how they work together to generate power and ensure smooth operation. The arrangement affects everything from fuel efficiency to overall reliability and performance.

Each element within the engine has a specific function, contributing to its operation. The engine block serves as the core foundation, housing critical components such as pistons and crankshafts. These components work in unison to convert fuel into mechanical energy. Other systems, such as cooling and lubrication, are strategically placed to maintain optimal temperatures and reduce friction.

Proper layout design also ensures the longevity of the engine. A balanced arrangement minimizes wear and tear on parts, ensuring a longer lifespan and better overall efficiency. For maintenance and repair tasks, understanding the engine layout is essential to diagnosing issues and making informed decisions about which components require attention.

Essential Components of the Engine

Every engine is made up of key components that play a vital role in ensuring proper function and efficiency. Understanding these critical elements is essential for anyone involved in the maintenance, repair, or operation of the engine. Each part works together to convert energy and provide power, and their condition directly affects overall performance.

The engine block is the central unit, housing the vital moving parts such as pistons, crankshaft, and camshaft. These elements are responsible for converting combustion energy into mechanical force. Surrounding systems, such as the fuel and exhaust systems, ensure that the engine receives the proper fuel and expels gases efficiently.

Other important components include the cooling system, which maintains optimal operating temperatures, and the lubrication system, which reduces friction and wear between moving parts. Understanding how each of these parts functions and interacts is crucial for maintaining engine performance and avoiding potential breakdowns.

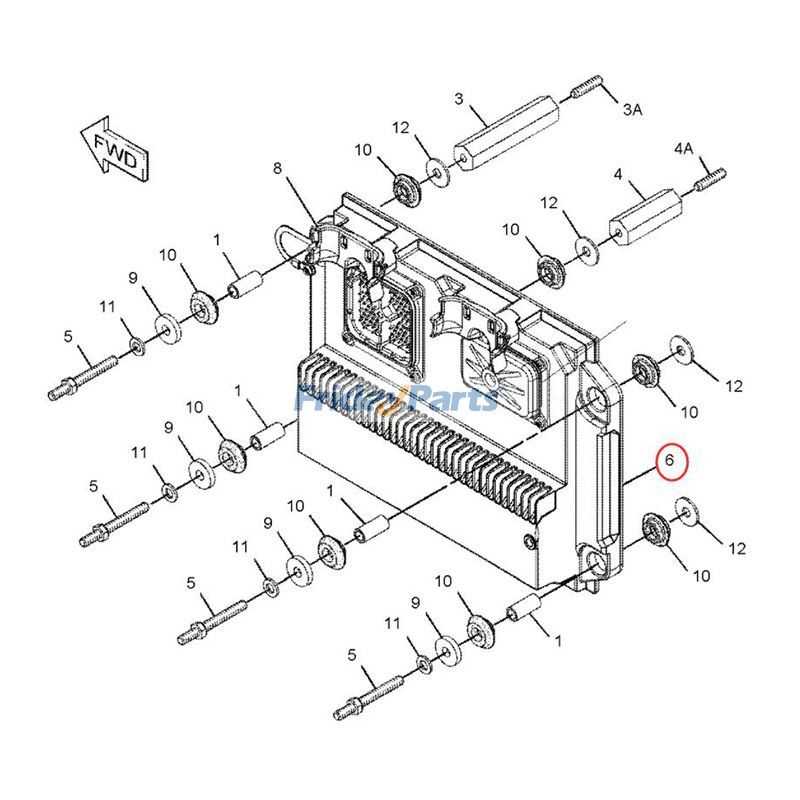

How to Use the Engine Layout Effectively

Understanding the layout of an engine is crucial for both diagnostics and maintenance. An accurate representation of the engine’s structure helps technicians identify specific components, locate potential issues, and guide repair procedures. Properly utilizing a layout allows for efficient problem-solving and ensures that each part is correctly serviced or replaced when necessary.

To use the engine layout effectively, begin by familiarizing yourself with the various sections and components shown. Start with the core elements, such as the engine block and its major moving parts. Knowing where each component is located helps you pinpoint areas that may require attention or further inspection. Cross-referencing the diagram with the actual engine can provide additional context to ensure accurate work.

As you proceed with repairs or maintenance, the diagram can also help you follow a logical sequence, preventing missed steps or incorrect handling of components. Clear identification of components is essential for ensuring that each part is aligned and reassembled correctly. This practice not only streamlines the process but also minimizes the risk of errors and enhances overall engine performance.