Understanding the inner workings of your tools is essential for proper maintenance and troubleshooting. Whether you’re looking to repair a malfunctioning unit or perform routine upkeep, knowing how all the components fit together is crucial for a smooth process.

Accurate identification of each part and its function ensures that repairs are done efficiently and that your equipment continues to perform at its best. The ability to recognize specific pieces and understand their roles will help you avoid unnecessary errors and save time on repairs.

Having access to a clear, organized breakdown of your equipment’s structure can also prevent potential damage caused by missteps during assembly or disassembly. This guide provides you with the necessary tools to tackle your project confidently and effectively.

Complete Equipment Breakdown

Understanding the individual components of your tool is vital for maintaining its performance and extending its lifespan. A comprehensive overview of all its elements allows you to identify each part’s function and how they interact with one another. This knowledge enables you to address specific issues and replace damaged pieces when necessary.

Each section of the equipment is carefully designed to work in harmony with the rest, and recognizing the roles of these elements helps prevent unnecessary repairs. Knowing the exact layout of every component makes troubleshooting much more efficient, whether you are dealing with a malfunction or performing routine maintenance.

This breakdown provides a detailed look at how every piece contributes to the overall operation. With clear identification and understanding of each element, you can confidently perform repairs, upgrades, or replacements, ensuring that your tool operates optimally for a long time.

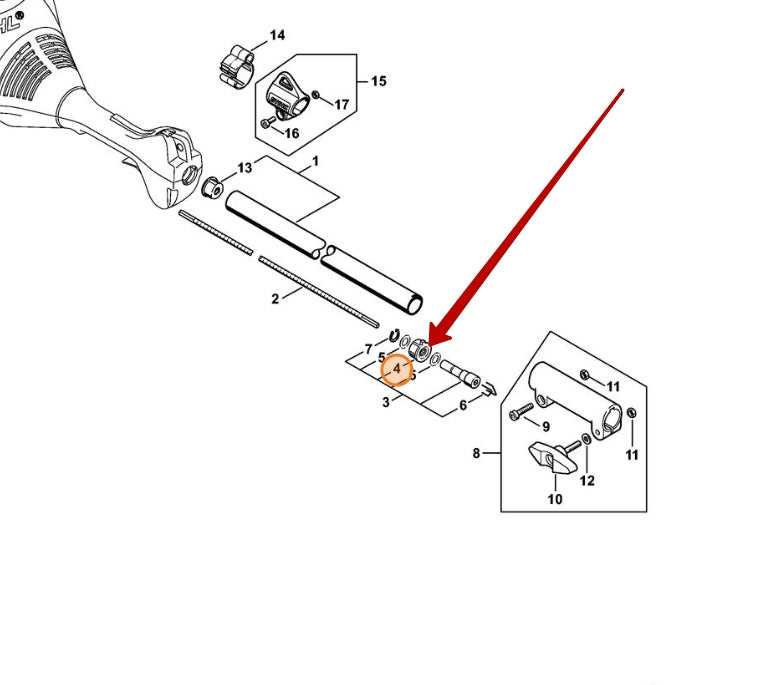

How to Read Equipment Layouts

Interpreting technical schematics requires an understanding of the visual representation of a tool’s components. These illustrations are designed to give you a clear view of how each element is arranged and how they interact. Recognizing the symbols and lines that connect different parts can provide insight into their relationships and functionality.

Each section of the layout is labeled with specific references that correspond to particular components. These labels help you identify each part’s location and role within the overall system. Understanding these references allows you to pinpoint exactly where a problem may exist and which parts need attention or replacement.

By familiarizing yourself with the visual conventions used in these layouts, you can navigate them more efficiently. Recognizing patterns in the way parts are drawn and linked will enable you to understand the tool’s structure and work on repairs with confidence.

Maintaining Your Equipment

Regular upkeep is essential to ensure your tool continues to function effectively and reliably over time. A proactive maintenance routine can help avoid unexpected malfunctions and extend the life of the equipment. Proper care involves checking for wear and tear, cleaning key components, and replacing parts that show signs of damage.

Routine Cleaning and Inspection

Cleaning the tool after each use is one of the most important steps in maintenance. Dirt, debris, and moisture can cause parts to deteriorate more quickly. Inspecting the unit for any loose or worn-out components will help identify potential issues before they become serious problems. Regularly check filters, air intakes, and moving parts to ensure everything is functioning properly.

Timely Part Replacements

Replacing damaged or worn components at the right time ensures optimal performance. Keeping an eye on frequently used parts, such as the drive system and cutting elements, can prevent unexpected breakdowns. Always use high-quality replacements to maintain the tool’s efficiency and reliability.

By following a consistent maintenance schedule, you will not only avoid costly repairs but also ensure that your equipment operates at peak performance throughout its lifespan.