When maintaining or repairing your lawn mower, understanding its internal structure is crucial. Every model consists of various elements that work together to ensure proper operation, and knowing how each piece functions can make a significant difference in handling repairs and regular care. A clear view of how these components are organized can save time and effort during the maintenance process.

Maintenance efficiency relies on being able to identify and understand the layout of each part, from the engine components to the wheel mechanisms. This can help detect problems early, such as worn-out components or misaligned parts, which can affect performance.

By learning the exact arrangement and functions of your equipment, you can troubleshoot common issues with ease. Familiarity with its construction will enable you to make informed decisions about repairs, replacements, and upgrades, ensuring your mower stays in top condition for a long time.

Understanding the Lawn Mower Components

Knowing the internal structure of your equipment is key to effective operation and long-lasting performance. The machine is made up of several key components that must work in harmony to ensure smooth functioning. A deep understanding of each element’s role can help you maintain and repair your mower with confidence.

Main Engine and Drive System

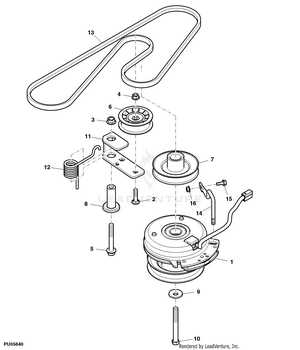

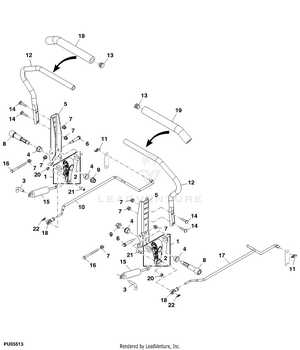

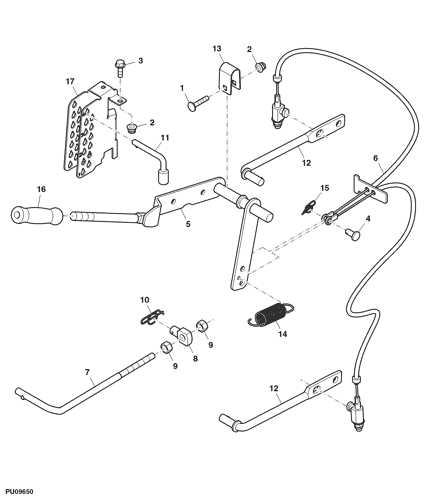

The engine serves as the heart of the machine, generating the necessary power to propel the mower and drive the cutting mechanism. Key elements such as the spark plug, carburetor, and air filter play crucial roles in maintaining engine efficiency. The drive system, composed of belts, pulleys, and gears, connects the engine’s power to the wheels, allowing the mower to move and maneuver across your lawn.

Cutting Mechanism and Deck

The cutting deck is another important section, housing the blades and other components that trim your grass. The height adjustment lever allows you to set the desired cutting length. The blades, often powered by the drive system, rotate to cut the grass evenly and efficiently. Regular maintenance of this section ensures your mower performs at its best, leaving a neat, well-maintained lawn.

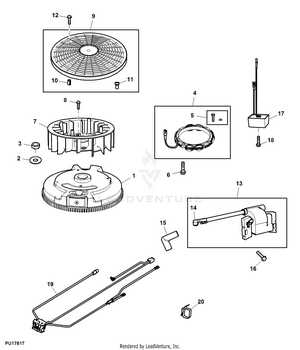

How to Identify Key Components in the Diagram

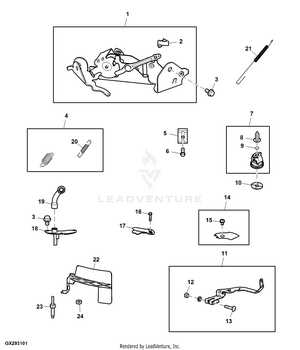

Understanding the key components of your machine is essential for performing accurate diagnostics and ensuring proper maintenance. By referring to a clear, detailed layout, you can easily locate and recognize each part, helping you identify potential issues or necessary replacements. Familiarity with the structure of the equipment allows for more efficient troubleshooting and repairs.

The first step is to familiarize yourself with the layout, paying attention to how parts are organized and connected. Begin by identifying the major components such as the engine, transmission, and cutting mechanisms. These are typically larger, central pieces that are essential to the overall functioning of the equipment.

Next, focus on the smaller parts that support these major components, such as belts, pulleys, and springs. These may not be immediately obvious, but they play a crucial role in the operation of the machine. Once you can pinpoint these components in the visual reference, you’ll be able to track down specific issues more easily when they arise.

Step-by-Step Guide to Mower Maintenance

Regular upkeep is essential for keeping your machine in optimal working condition. Following a structured maintenance routine can extend the lifespan of the equipment, improve its performance, and prevent unexpected breakdowns. By adhering to a step-by-step approach, you can ensure that all parts remain in good shape and function smoothly.

Start by inspecting the main components of the machine, focusing on areas that experience frequent wear and tear. This proactive approach helps identify issues before they become major problems. Here’s a breakdown of the key steps:

- Check and Replace the Air Filter: Over time, the air filter can become clogged, affecting engine performance. Clean or replace it as needed to ensure proper airflow.

- Inspect the Blades: Examine the cutting blades for any signs of damage or dullness. Sharpen or replace them to ensure clean, efficient cuts.

- Change the Oil: Regular oil changes are crucial for engine health. Drain the old oil, replace the filter, and refill with fresh oil according to the manufacturer’s recommendations.

- Examine Belts and Pulleys: Check the belts and pulleys for wear or damage. Replace any worn-out parts to prevent operational issues.

- Clean the Deck: Grass and debris can build up under the cutting deck, affecting performance. Clean the area regularly to avoid clogging and improve cutting efficiency.

- Test the Battery: Ensure the battery is fully charged and check for any signs of corrosion on the terminals. Clean the terminals and replace the battery if necessary.

Following these steps regularly will help you maintain the equipment and avoid costly repairs. Always refer to the owner’s manual for specific guidelines and maintenance intervals to ensure you are properly caring for each component.

Important Parts to Check Regularly

Maintaining the functionality of your machine requires consistent inspection of its most crucial components. Regular checks ensure smooth operation and help detect potential issues early, preventing costly repairs or unexpected breakdowns. Understanding which parts need frequent attention will enable you to keep the equipment running efficiently throughout its lifespan.

Engine and Fuel System

The engine is the heart of the machine, and keeping it in good working condition is essential for overall performance. Regularly inspect the air filter, spark plugs, and fuel lines for any signs of wear or clogging. Replacing the air filter and cleaning the spark plugs can help the engine run more efficiently and prevent starting issues. Additionally, ensure the fuel system is free from leaks or blockages.

Cutting Mechanism and Deck

The cutting mechanism requires consistent care to ensure a clean and even cut. Check the blades for sharpness and any signs of damage. Dull or bent blades can result in uneven cuts or damage to the grass. Inspect the cutting deck for debris buildup and clean it regularly to maintain optimal performance. This also helps prevent potential clogs and ensures smooth operation while mowing.

Troubleshooting with the Mower Component Breakdown

When issues arise with your equipment, having a clear understanding of its structure can significantly speed up the troubleshooting process. By referring to a detailed layout of the machine, you can identify the source of the problem and address it with precision. Knowing where each component is located and how it functions allows for quicker diagnostics and efficient repairs.

If you notice that the mower is not starting, begin by inspecting the engine components such as the fuel system, spark plug, and air filter. These parts are often the cause of starting issues. If the engine runs roughly, check the fuel lines and carburetor for blockages or leaks. A clogged fuel filter or dirty carburetor can hinder engine performance.

In cases of poor cutting quality, focus on the cutting deck and blade assembly. Dull or damaged blades, along with debris buildup under the deck, can cause uneven cuts. Additionally, ensure that the height adjustment mechanism is functioning properly. A faulty belt or misaligned pulley may affect the drive system and impact the mower’s ability to maintain consistent speed and power.