Proper maintenance of lawn mowers requires a clear understanding of their internal structure. Knowing the arrangement of key elements helps ensure smooth operation and efficient repairs. Whether you’re performing routine checks or replacing worn-out components, recognizing each part’s role is essential.

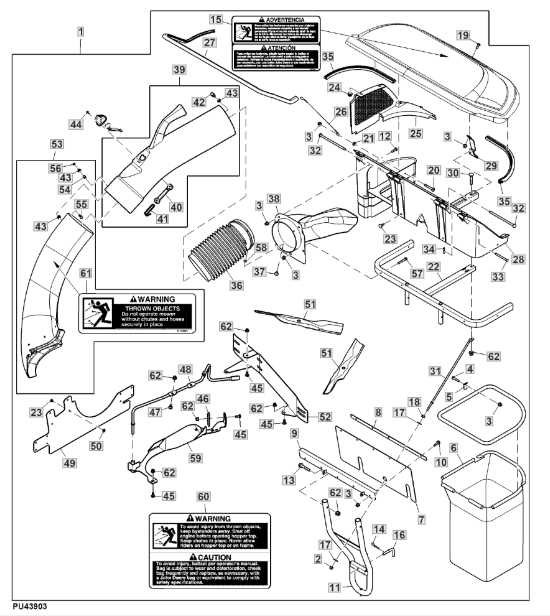

In this section, we will explore how to navigate the detailed component maps of mowers. These visual aids break down each segment of the machine, offering a clear guide to where each part fits within the system. Understanding these layouts can save both time and effort when working on your mower.

Additionally, identifying common issues with specific components becomes easier once you are familiar with their positioning. Knowing what to look for can prevent unnecessary troubleshooting and reduce the chances of costly repairs. Familiarity with the entire system leads to better overall performance and longer-lasting equipment.

Understanding the Lawn Mower Components

Maintaining a lawn mower requires knowing the various elements that work together to ensure proper functionality. Each component plays a crucial role in the overall performance, and understanding their layout can make repairs and maintenance tasks much easier.

These machines consist of several key sections, including the engine, transmission, cutting system, and frame. Identifying each part within the system helps you pinpoint potential issues, perform necessary adjustments, and ensure smooth operation over time. Having a clear understanding of how each component interacts with the others is vital for efficient maintenance.

By becoming familiar with the specific parts of the equipment, you can also anticipate which components are more prone to wear and tear. Regular checks and knowing which parts need periodic replacement will not only extend the lifespan of your machine but also improve its overall performance.

How to Read the Lawn Mower Component Layout

Understanding how to interpret a machine’s component layout is essential for successful repairs and maintenance. These visual aids provide an organized view of the machine’s internal structure, allowing you to quickly locate and identify specific elements. By becoming familiar with this system, you can perform tasks more efficiently and confidently.

Key Features to Focus On

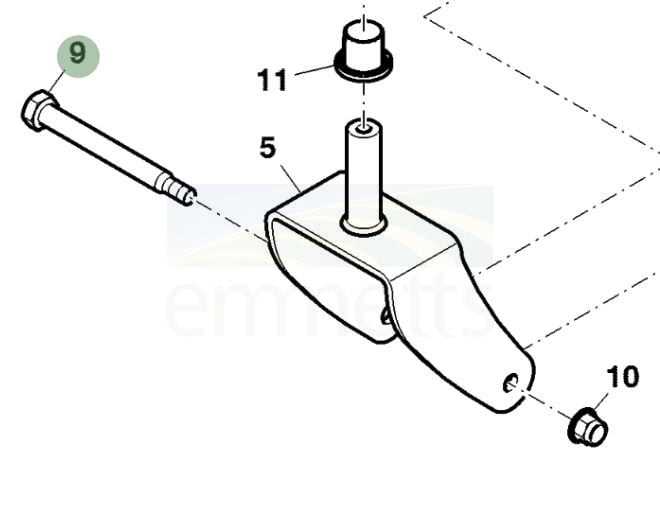

- Labels: These typically indicate each component’s name or part number for easy identification.

- Connections: Lines and arrows represent the connections between different parts, showing how they work together.

- Location: The placement of each part within the overall machine layout is clearly marked to avoid confusion during disassembly or repairs.

Steps to Follow When Reading the Layout

- Begin by familiarizing yourself with the overall layout of the machine, focusing on major components.

- Look for labels and part numbers to help you identify each individual component.

- Use arrows or lines to understand the relationships between parts and how they interact with one another.

- Keep track of the sequence of parts, especially when replacing components in the correct order.

Once you get the hang of reading the layout, you’ll be able to quickly identify which parts need attention, saving time during repairs and preventing potential mistakes. Being able to follow this guide will make it easier to perform maintenance tasks and replace parts as needed.

Common Replacements for Lawn Mower Components

Over time, certain elements of a lawn mower will inevitably wear out due to regular use. Identifying the parts that require replacement is crucial for keeping the machine in good working condition. Knowing which components commonly need attention can help you plan your maintenance routine and avoid unexpected downtime.

Frequently Replaced Components

- Blades: These are subject to wear and can become dull or damaged, affecting the cutting performance. Regular sharpening or replacement is necessary for optimal results.

- Belts: The belts that drive the cutting deck or transmission may stretch, crack, or snap over time, requiring replacement to maintain smooth operation.

- Air Filters: Air filters prevent debris from entering the engine, and when clogged, they can affect performance. It’s recommended to replace them periodically for proper airflow.

- Spark Plugs: Spark plugs are essential for engine ignition. If they become fouled or damaged, they can lead to poor starting and engine performance.

Signs That Indicate the Need for Replacement

- Visible damage such as cracks, breaks, or significant wear.

- Decreased performance, such as reduced cutting efficiency or difficulty starting the engine.

- Unusual noises or vibrations during operation, which can signal that a component is malfunctioning.

Being proactive about replacing worn components will extend the lifespan of your machine and improve its performance. Regular inspections and timely replacements will ensure that your equipment continues to function effectively for years to come.