For any lawn care professional or enthusiast, maintaining and repairing machinery is essential to ensure long-lasting performance. A well-organized guide to the individual elements of a mower can greatly simplify the process of identifying issues and replacing components.

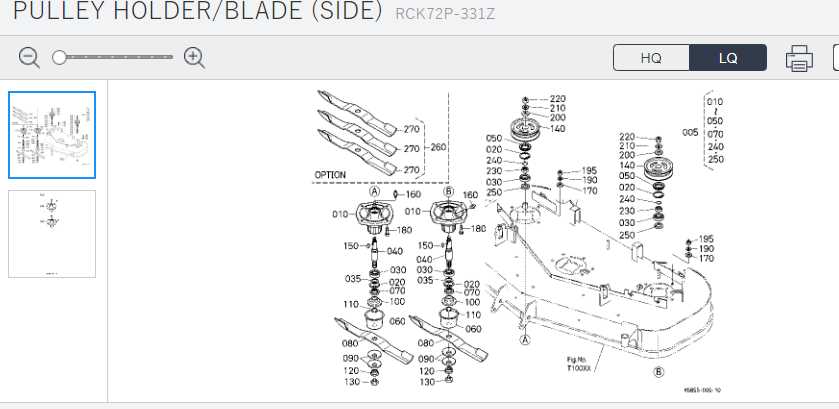

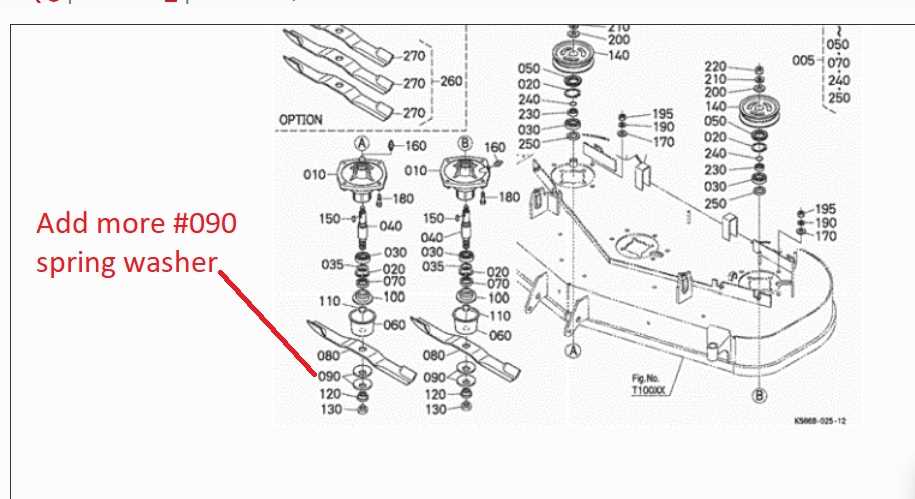

Having a clear visual representation of all the machine’s components helps users quickly locate parts and understand their connections. This can significantly reduce troubleshooting time and aid in making informed decisions regarding repairs or maintenance.

Recognizing key features in a mower’s design can also help in avoiding mistakes during assembly or disassembly. With the right tools and a structured approach, fixing or upgrading equipment becomes much easier and more efficient.

Understanding Kubota ZD331 Parts Layout

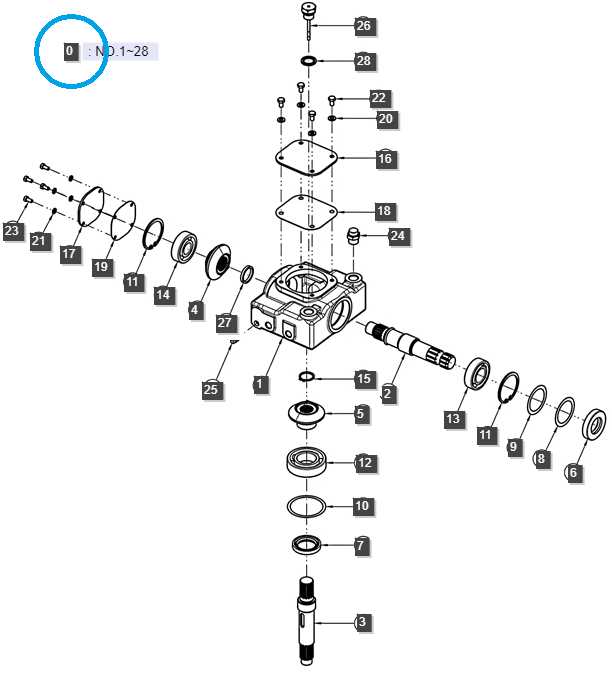

Proper understanding of a machine’s internal structure is key to maintaining and repairing it effectively. The layout of various components plays a crucial role in ensuring smooth functionality, as it helps users identify parts quickly and accurately. A comprehensive overview of this layout provides insight into the relationship between different elements and aids in pinpointing potential issues.

By examining the arrangement of major sections and their respective functions, operators can gain a clearer picture of how each part contributes to the overall performance of the equipment. This knowledge can be particularly useful when dealing with complex systems, where a small malfunction in one area can affect multiple others.

Familiarity with the component layout also empowers users to perform routine maintenance tasks with confidence. Understanding how the elements are positioned and connected ensures that assembly or disassembly is done properly, reducing the risk of errors and improving the lifespan of the machine.

How to Use the Kubota ZD331 Diagram

Using a visual guide to identify components and their placements is an essential skill for effective maintenance and repairs. These guides provide a clear map of how various elements are connected, allowing users to quickly locate any part and determine its function. A well-structured schematic can be invaluable when troubleshooting issues or performing regular upkeep.

Start by identifying major sections such as the engine, transmission, and electrical systems. Once you have a basic understanding of the layout, use the diagram to zoom in on specific areas that require attention. This allows for more focused work and helps avoid unnecessary disassembly of unrelated components.

When following the diagram, always cross-reference the numbers or labels on the schematic with the actual machine. This ensures you’re working with the correct part and prevents confusion. Proper use of these visual tools will streamline repairs and make the process more efficient, saving both time and effort.

Common Repairs with Kubota ZD331 Parts

Regular maintenance and timely repairs are essential for keeping any machine running smoothly. Common issues often stem from wear and tear on key components, which can lead to decreased efficiency or even breakdowns. Understanding the most frequent repairs allows owners to be proactive, addressing potential problems before they worsen.

Engine and Transmission Maintenance

One of the most common repair areas involves the engine and transmission systems. Over time, these parts may experience mechanical failures due to prolonged use, resulting in poor performance or total failure. Regularly checking and replacing worn-out belts, seals, or filters can help prevent these problems. Moreover, ensuring proper lubrication and cooling can extend the lifespan of these critical components.

Electrical System Troubleshooting

Another frequent issue arises in the electrical system, where damaged wiring or faulty connections can cause problems with starting the machine or controlling its various functions. Inspecting wiring regularly for signs of fraying or corrosion is essential. If issues arise, replacing damaged wires or connections often restores full functionality.