When it comes to maintaining a lawn mower, understanding its internal components is essential for smooth operation and lasting performance. Knowing how the different parts fit together allows for quicker repairs and better care of your equipment.

By familiarizing yourself with the layout of key elements, you’ll gain the ability to identify problems early and perform repairs with confidence. This knowledge ensures that you can keep your mower in peak condition without the need for constant professional assistance.

Whether you’re dealing with a small malfunction or performing routine checks, having a clear reference for how everything is organized can make the job significantly easier. Proper maintenance not only extends the lifespan of your mower but also ensures it works at maximum efficiency for every task.

Understanding Lawn Mower Component Layout

Knowing how each section of your machine is arranged is key to proper maintenance. The internal configuration of your equipment impacts both its functionality and longevity, so it’s important to familiarize yourself with how each element works together. Having a clear understanding of this layout can simplify troubleshooting and enhance your repair skills.

Key Sections of the Machine

Every lawn mower consists of several main components, including the engine, transmission system, and blade assembly. These sections are interconnected, and understanding their arrangement can help you pinpoint issues quickly. For example, if the engine isn’t running smoothly, it could be due to a problem with the fuel system or electrical wiring.

Identifying Common Issues

Familiarity with how the different parts are laid out allows you to identify common problems, such as a malfunctioning starter or a worn-out belt. By visually inspecting each area, you can often detect wear and tear or other signs of damage before they become serious issues. Regular checks ensure your machine continues to operate at peak performance.

How to Use the Component Layout Effectively

Understanding how to navigate a detailed visual reference of your machine’s configuration can significantly improve your maintenance and repair processes. A well-organized schematic offers a clear view of all the essential parts and their connections, allowing for more precise and efficient troubleshooting.

Familiarizing Yourself with Key Sections

Before using the visual guide, take time to familiarize yourself with the primary groups and components. Start by identifying the major sections such as the engine, drive system, and cutting mechanisms. By learning the layout of these sections, you can more easily locate specific parts when performing repairs or maintenance tasks.

Step-by-Step Repair Assistance

When faced with a malfunction, refer to the schematic for step-by-step guidance on how to access and replace faulty components. The visual guide breaks down each section into smaller parts, helping you understand the order of assembly and disassembly. This approach minimizes mistakes and ensures that your repair process is efficient and accurate.

Common Lawn Mower Repair Components

Every lawn mower includes several critical components that, over time, may require attention or replacement. These essential parts are subject to wear and tear due to regular use, making it important to know which ones are most likely to need servicing or replacement. Being familiar with these key components helps ensure your mower continues to function efficiently.

Engine and Fuel System

The engine is the heart of the mower, and issues with the engine often stem from problems in the fuel system. Common components like the fuel filter, carburetor, and spark plug should be regularly checked for clogs or damage. If the engine struggles to start or runs irregularly, examining these parts can often reveal the underlying problem.

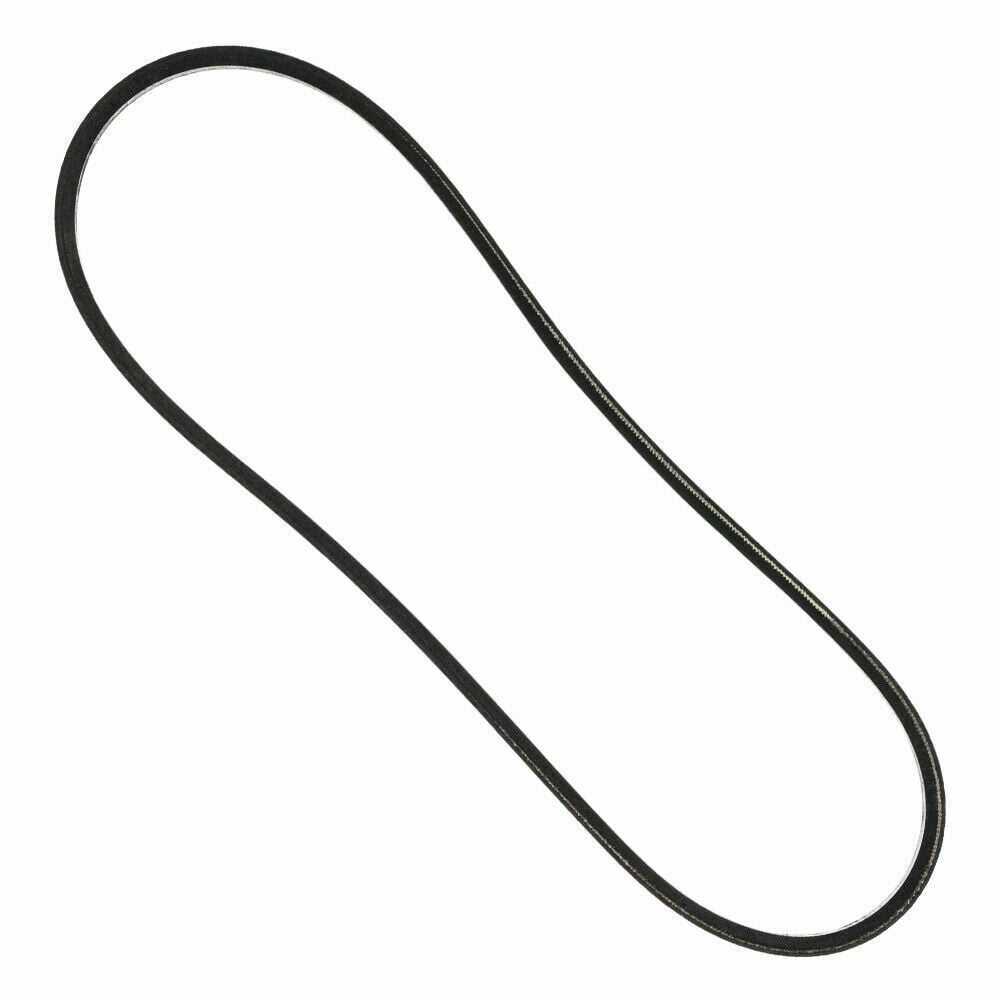

Drive Belt and Blade Assembly

The drive belt transfers power from the engine to the wheels, and it can wear out over time. Similarly, the blade assembly, responsible for cutting the grass, is subject to frequent wear. Regular inspection of these parts can prevent poor performance and ensure clean, even cuts. Replacing worn belts and dull blades is essential for maintaining optimal function.