Proper maintenance is essential for keeping your outdoor tools in top condition. Understanding the structure and components of your device can greatly enhance its longevity and performance. In this guide, we explore the key elements that make up your machine and provide practical tips on how to handle any maintenance or repairs.

Every device is made up of various interconnected parts that work together to perform its tasks. Recognizing each piece and its function helps in identifying potential issues and allows you to address them with confidence. Whether you’re troubleshooting or performing regular upkeep, knowing what each component does is crucial for effective maintenance.

By following the steps outlined in this article, you will be equipped to manage basic repairs and prevent common problems. A well-maintained machine not only performs better but also saves you time and money in the long run. Take control of your tool’s health with the right knowledge and approach.

Understanding Stihl FS 131 R Components

Every tool consists of various interconnected elements that play specific roles in ensuring smooth operation. Each component, from the engine to the cutting mechanism, contributes to the overall performance. Familiarity with these key elements is crucial for proper upkeep and troubleshooting.

Typically, these machines feature a robust engine system, a flexible drive shaft, and a durable cutting attachment. The engine is the powerhouse, converting fuel into motion, while the drive shaft transmits this power to the working parts. The cutting mechanism, such as blades or string, is responsible for the tool’s main function of trimming or clearing vegetation.

By understanding the relationship between each component, users can identify wear and tear or potential issues early on. Proper maintenance relies on recognizing the signs that each element provides, allowing you to take necessary actions to prevent malfunctions and ensure peak efficiency.

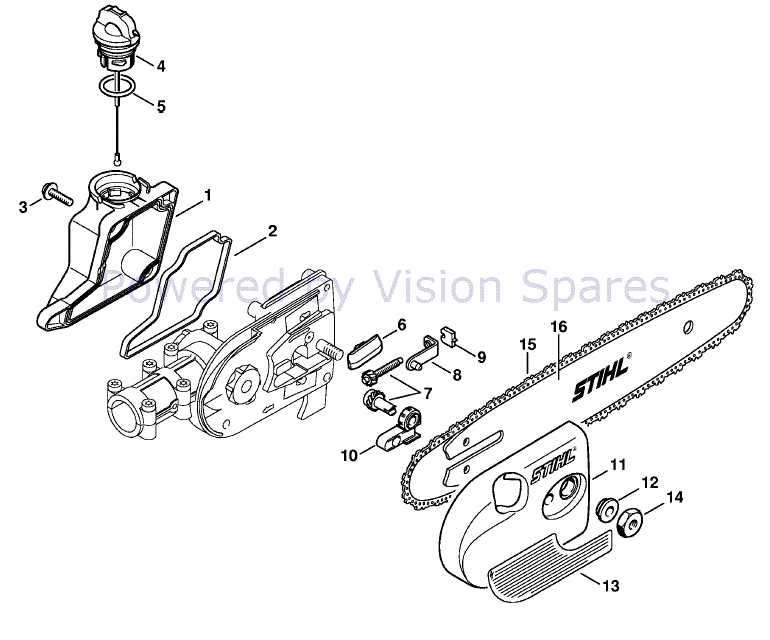

How to Identify Stihl FS 131 R Parts

Knowing how to identify the individual components of your machine is crucial for effective maintenance and repair. Each element plays a distinct role in the overall functionality of the tool, and recognizing them helps ensure proper operation and timely fixes when needed. By understanding what each part does, you can take action to maintain or replace it when necessary.

Visual Inspection

The first step in identifying any component is through visual inspection. Carefully examine the tool, paying attention to the main sections such as the handle, engine casing, and cutting head. Often, parts are labeled or designed in specific ways to make identification easier. Look for numbers or markings that correspond to a manual or online resource for further details on each element.

Consulting the Manual

The user manual is an invaluable resource when identifying and understanding the function of various elements. It usually includes detailed illustrations or images, labeling key parts and providing information on their purpose. If you are unsure about a particular component, this guide can offer a reference point to confirm your observations and avoid confusion.

Stihl FS 131 R Maintenance Tips

Regular upkeep is essential to keep your outdoor equipment running smoothly. Proper maintenance not only extends the life of the machine but also ensures it operates at peak efficiency. Simple tasks, such as cleaning and lubrication, can prevent common issues and reduce the need for costly repairs.

Routine Maintenance Tasks

A well-maintained tool requires consistent attention. Follow these basic steps to keep your device in optimal condition:

- Clean the machine after each use to remove debris and dirt.

- Check the fuel system for leaks or damage, and ensure the fuel is fresh.

- Lubricate moving parts to prevent friction and wear.

- Inspect the cutting mechanism for dullness or damage.

Signs That Maintenance Is Needed

Watch for these common signs that your tool might need attention:

- Reduced power or difficulty starting the machine.

- Excessive vibrations during operation.

- Strange noises coming from the engine or drive system.

- Visible damage to the cutting head or drive shaft.

By staying proactive and performing routine maintenance, you can avoid unexpected failures and ensure that your equipment remains reliable for years to come.