In any advanced mechanical system, the interaction between various components plays a crucial role in ensuring smooth operation and efficiency. The structure that facilitates this balance is composed of several integral elements, each designed to handle specific tasks. Understanding how these elements come together is essential for maintaining high-performance machinery.

The combination of key elements, such as pressure plates, springs, and other interlocking parts, provides the necessary functionality for reliable power transmission. These components work in harmony to ensure smooth engagement and disengagement during operation, making them vital for optimal performance.

By examining the individual components and their interactions, one can gain a clearer understanding of how mechanical energy is transferred and controlled within the system. Knowing the role of each piece allows for more effective troubleshooting and maintenance, ultimately enhancing the longevity and reliability of the entire assembly.

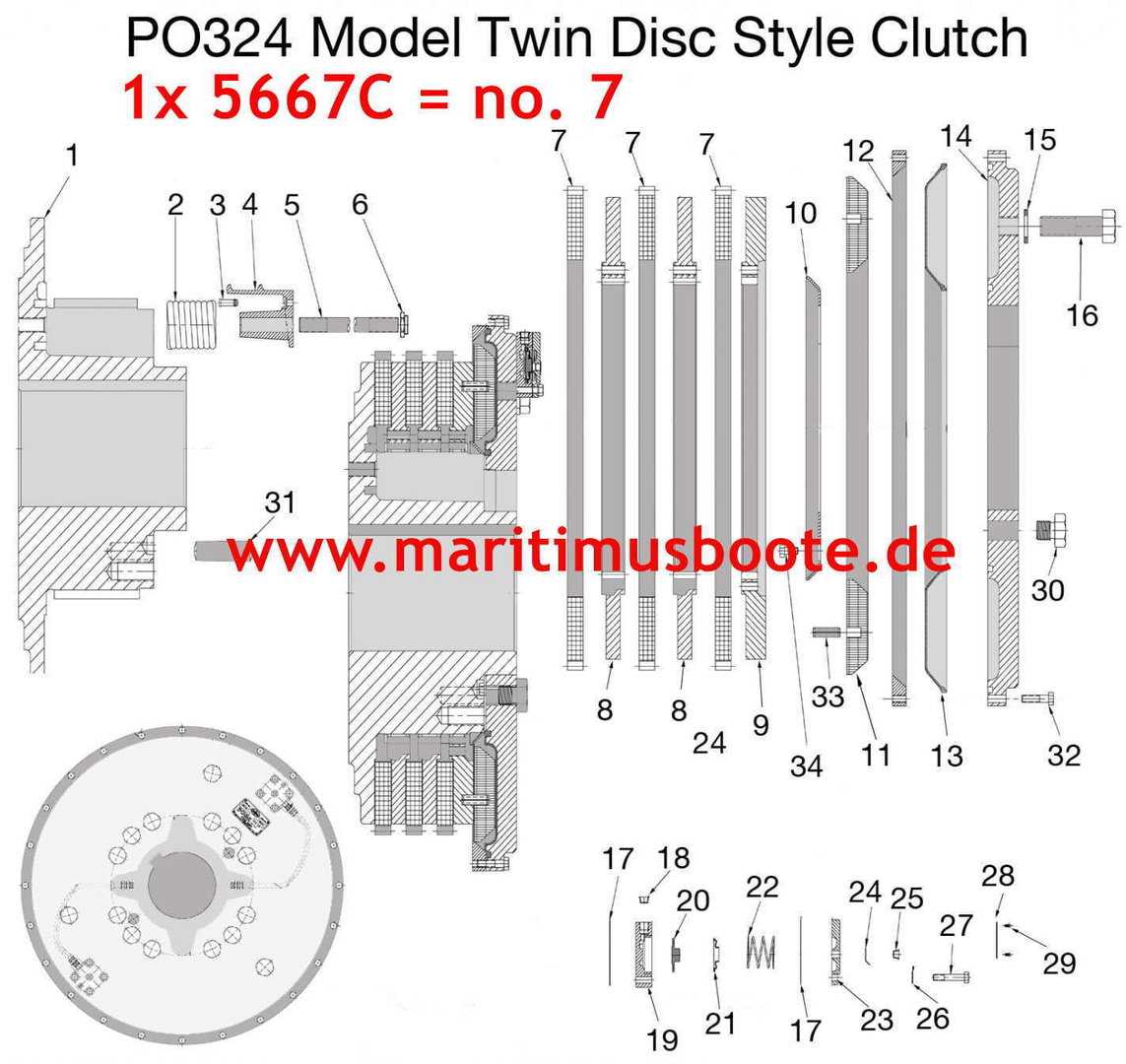

Understanding Twin Disc Clutch Design

In complex mechanical systems, the design of the mechanism that connects the engine to the transmission is essential for efficient power transfer. A well-engineered configuration ensures smooth operation, minimizing wear and maximizing performance under various conditions. The design involves multiple elements that cooperate seamlessly, each serving a specific function to enable reliable energy transmission.

Key Elements of the Design

The structure consists of interdependent components, each contributing to the smooth engagement and disengagement process. These elements are crucial for maintaining balance and reducing friction. The key components include:

- Pressure Plates: These plates create the force needed to press the friction surfaces together, ensuring power transmission when engaged.

- Friction Discs: These provide the necessary resistance for transferring power smoothly, facilitating engagement and disengagement.

- Springs: Springs maintain tension and ensure that the pressure plates function correctly, controlling the engagement force.

- Flywheel: This part helps maintain rotational momentum, improving the system’s overall stability.

Interconnected Design for Optimal Performance

Each element in the system is designed to work in harmony with the others, allowing for effective control of torque. The spacing, materials, and design of each part play a critical role in ensuring optimal performance under various conditions. When all components function together, the system can efficiently handle high loads while minimizing heat buildup and wear.

Understanding the design allows for better maintenance and troubleshooting, helping technicians identify potential issues before they cause failure. This insight also aids in improving the system’s longevity and reliability, ensuring that it operates at peak efficiency for longer periods.

Key Components of Twin Disc Clutch

The effectiveness of any system relying on mechanical engagement and disengagement depends on the careful design and integration of several critical elements. These components work in tandem to ensure that the system operates smoothly under varying conditions, providing consistent performance and minimizing potential failure points. Each element plays a unique role in the process of transferring mechanical energy efficiently.

Main Elements in the Assembly

Among the most important parts of this mechanism are the following:

- Pressure Plates: These create the necessary force to engage the friction surfaces and transmit power when activated.

- Friction Materials: These components are crucial for power transfer, providing resistance that allows for controlled engagement and disengagement.

- Springs: Springs maintain the necessary pressure on the pressure plates, ensuring they function correctly while preventing excessive force or slipping.

- Flywheel: The flywheel helps stabilize rotational forces and maintains momentum, contributing to smoother operation and reducing strain on other components.

The Role of Each Element

Each component is designed to interact seamlessly with others, ensuring balanced operation across the system. For example, the pressure plates create the force needed to press the friction surfaces together, while the flywheel ensures consistent rotational momentum. The springs ensure that all parts maintain the correct tension and engagement throughout the system’s operation, reducing wear and tear over time.

These critical elements together form a highly reliable system capable of transmitting power efficiently, making them essential for maintaining system longevity and performance.

How Twin Disc Clutch Works Together

For any mechanical system designed to transfer energy smoothly, the interaction between its key components is crucial. Each part must function in unison to enable seamless power transfer, ensuring that forces are managed efficiently without causing damage or excess wear. This intricate process requires precise coordination between several elements, each contributing its role to the overall mechanism.

Coordinated Action of Components

The interaction begins when the engine produces rotational force, which must be transmitted to the transmission system. The pressure plates apply force on the friction surfaces, ensuring they are tightly engaged, allowing power to flow. As the force is applied, the springs help maintain constant pressure, while the flywheel stabilizes the system’s rotation and minimizes shocks. Together, these components manage torque, ensuring smooth transitions and avoiding sudden jerks.

Efficient Power Transfer

As the system operates, the friction materials generate resistance, enabling smooth engagement and disengagement as needed. When the mechanism is disengaged, the springs help separate the components, releasing pressure and reducing friction. When engaged, the friction materials create the necessary resistance for transferring power. This balance of forces ensures that the system remains efficient and reliable under various operational conditions.

By working in harmony, these interconnected parts provide a highly efficient method for power transmission, ensuring the system operates smoothly, reliably, and with minimal wear over time.