When maintaining your chainsaw, it’s essential to understand the different components and how they work together. Proper knowledge of the internal mechanisms not only aids in effective troubleshooting but also ensures smooth operation during use. By familiarizing yourself with the layout of essential elements, you can extend the lifespan of your equipment and prevent unnecessary wear and tear.

Whether you’re a seasoned professional or a hobbyist, understanding the specific parts and their functions is critical for performing accurate repairs and upgrades. With clear identification of each component, you can easily spot any issues and address them promptly. This knowledge also helps in assembling and disassembling the tool with greater ease.

Having a comprehensive understanding of the various pieces in your chainsaw will give you confidence in managing routine maintenance and repairs. Recognizing each part’s role makes it simpler to troubleshoot problems and maintain efficiency over time. It’s a valuable skill that ensures you’re always ready for the next job.

Understanding Chainsaw Components

To keep your chainsaw running smoothly, it’s essential to have a deep understanding of the various elements that make up the machine. Each component plays a unique role in ensuring the tool operates efficiently, and knowing how they interact can significantly improve the overall maintenance process. With proper awareness, identifying issues becomes easier, and addressing them promptly prevents long-term damage.

Key Components of Your Chainsaw

A chainsaw is made up of several important pieces that work together to provide optimal performance. These include the engine, fuel system, cutting mechanism, and safety features. Understanding the function of each part can help when it comes time for cleaning, repairs, or replacing damaged elements. For example, the ignition system is crucial for starting the engine, while the cutting chain requires regular attention to maintain sharpness and efficiency.

How Components Affect Performance

The way each element functions directly impacts the overall performance of the chainsaw. For instance, improper fuel flow can result in poor engine performance, while a worn-out cutting chain may cause the tool to lose efficiency and create safety hazards. Regular inspection and knowledge of these components ensure that your tool is operating at its best.

How to Read a Component Layout

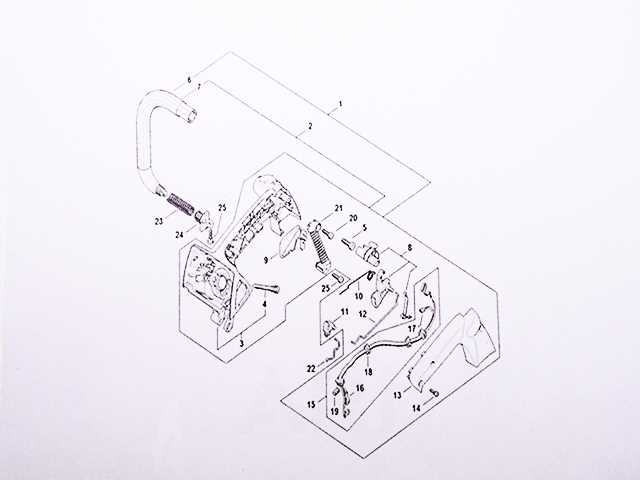

Understanding how to read a schematic of your tool’s components is crucial for any repair or maintenance task. These layouts provide a visual representation of all the essential elements and their placement within the machine. By familiarizing yourself with these images, you can easily locate specific parts, identify problems, and ensure that everything is reassembled correctly after disassembly.

Breaking Down the Visual Representation

Each schematic typically uses symbols and labels to indicate various components. Familiarizing yourself with these symbols will allow you to quickly recognize different parts, such as the engine, fuel system, or safety features. Some layouts also include part numbers and specific orientations, making it easier to determine how each piece fits into the larger assembly.

Using the Layout for Repairs

Once you understand the layout, it becomes an invaluable tool during repairs. Whether replacing a broken element or cleaning a specific section, the diagram allows you to know exactly what you’re working with. Accurate knowledge of this representation ensures that no part is overlooked, helping you perform tasks with precision and efficiency.

Common Repairs for Your Chainsaw

Regular maintenance and timely repairs are key to keeping your chainsaw in top working condition. Over time, certain components may wear out or become damaged due to frequent use, affecting the tool’s performance. Knowing the common issues and how to address them can save you time and money while ensuring your equipment remains reliable.

Replacing the Cutting Chain

One of the most frequent repairs involves the cutting chain. Whether due to dullness or damage, a worn chain can reduce the efficiency of the tool and make it harder to perform tasks. Replacing the chain is simple but requires careful attention to ensure the new one is installed properly and tensioned correctly. Regular inspection of the chain for signs of wear can help prevent performance issues.

Engine Troubleshooting

If the engine is not starting or is running poorly, it may be time to check for fuel or ignition problems. Common issues include clogged fuel filters, dirty spark plugs, or improper fuel mixture. Regular cleaning of the engine components can help avoid such problems. If necessary, replacing the spark plug or adjusting the carburetor will restore the engine to its optimal state.