Efficient water management systems are essential in commercial and industrial facilities. Proper functioning relies on a combination of mechanical components that work together seamlessly. Understanding how these elements interact can help ensure longevity and proper operation.

In this guide, we will explore the key components of a typical water control unit. By examining their design and role, you’ll gain insight into how each part contributes to the system’s overall performance. With this knowledge, maintenance and troubleshooting become more straightforward tasks.

Proper maintenance is critical to avoid unexpected breakdowns and reduce repair costs. By familiarizing yourself with the system’s elements, you can identify issues early and prevent potential malfunctions. This proactive approach will lead to more efficient and reliable operation.

Understanding Water Control System Components

Water management units in commercial and public facilities are complex devices composed of several interconnected elements. Each component has a specific function, contributing to the overall efficiency of the system. A clear understanding of these components allows for effective maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Elements of the System

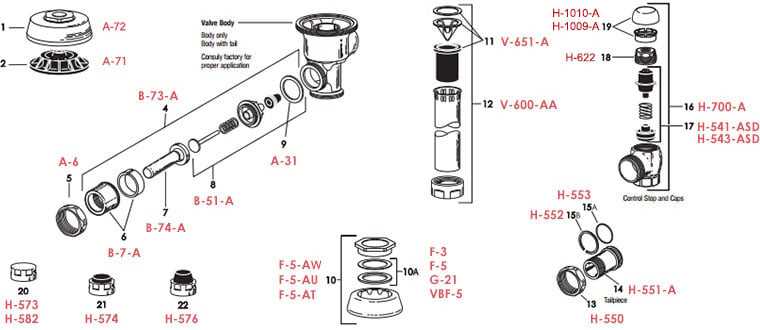

At the heart of the system, the valve regulates water flow and controls flushing actions. This mechanism is connected to a sensor or actuator that triggers the flushing cycle based on certain conditions. The pressure regulator ensures consistent performance even under varying water supply pressures. Additionally, seals and washers prevent leaks, maintaining both water conservation and system integrity.

Maintenance and Functionality

Proper maintenance of these elements ensures that the system continues to function smoothly. Regular inspection of the valve, seals, and pressure components can help detect potential issues before they lead to system failure. Replacing worn-out seals and calibrating pressure regulators are key steps in extending the lifespan of the unit.

Key Parts and Their Functions

Water control systems are made up of several essential components that work together to ensure proper operation. Each element plays a specific role in managing the flow of water, activating the flushing process, and maintaining the system’s efficiency. Understanding these key components is crucial for proper maintenance and troubleshooting.

The main component responsible for initiating the flushing cycle is the valve, which opens and closes based on the system’s needs. Connected to the valve is the actuator, which detects the presence of users and triggers the necessary actions. The pressure regulator helps maintain stable water flow, even when external supply conditions fluctuate. Additionally, seals and washers are critical for preventing leaks, ensuring that the system functions without wasting water.

Identifying Common Issues with Water Control Systems

Like any complex mechanism, water control units may experience problems over time. Identifying common issues early can prevent more significant damage and ensure the system continues to operate efficiently. Regular inspections and troubleshooting can help address these issues before they disrupt service.

Common Malfunctions

Several issues may arise with the system, ranging from water flow inconsistencies to complete malfunctions. Below are some of the typical problems encountered:

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent Water Flow | Clogged valve or low water pressure | Clean or replace the valve and check the pressure regulator |

| Water Leakage | Damaged seals or washers | Replace the worn-out seals and washers |

| System Fails to Activate | Faulty actuator or sensor | Inspect and replace the actuator or sensor if necessary |

Preventive Measures

By performing regular maintenance checks, users can avoid most common issues. Replacing damaged components like seals, cleaning internal parts, and ensuring proper calibration can significantly reduce the likelihood of malfunctions.

Maintenance and Troubleshooting Tips

Proper maintenance and timely troubleshooting are key to ensuring the longevity and efficiency of any water management system. Regular checks and quick responses to malfunctions can prevent costly repairs and extend the life of the equipment. Understanding how to maintain and troubleshoot common issues will help keep your system running smoothly.

Routine Maintenance

Routine maintenance is essential to avoid unexpected breakdowns. Regularly inspect key components like valves, seals, and pressure regulators to ensure they are functioning properly. Clean internal parts, lubricate moving components, and replace worn-out seals and washers. This proactive approach reduces the likelihood of performance issues.

Troubleshooting Common Problems

If problems arise, troubleshooting can often resolve them without requiring professional assistance. If the system fails to activate, check the sensors and actuators for malfunctions. For inconsistent water flow, inspect for clogs or check the water pressure. Always ensure that seals and washers are intact to prevent leaks. Identifying and addressing these issues early can save time and money.

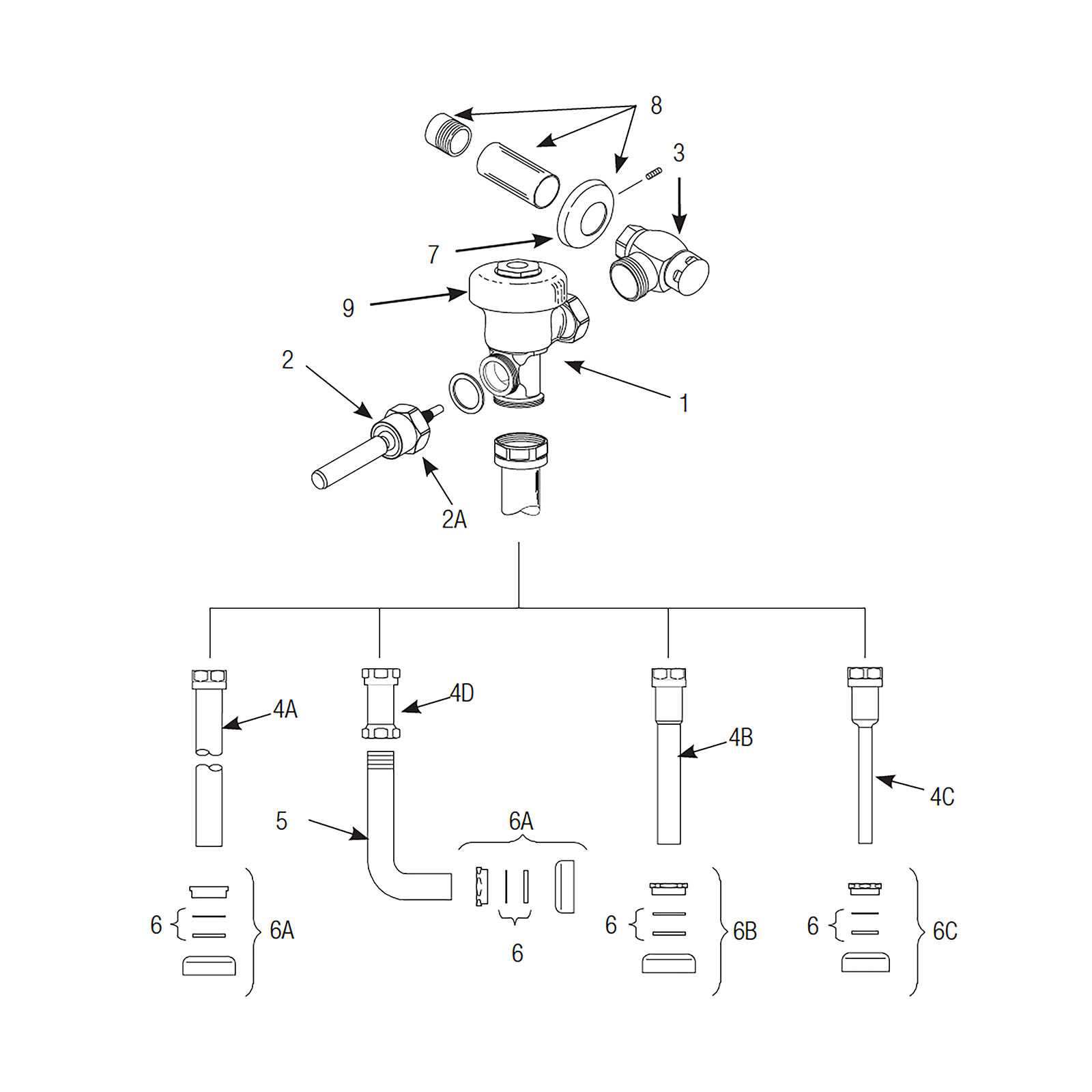

How to Replace Flushometer Parts

Replacing components of a water control mechanism can seem challenging, but with the right steps and tools, the task becomes straightforward. Whether you’re dealing with a malfunctioning valve or an inefficient flushing system, knowing how to replace individual elements is essential for restoring proper function. This guide will help you navigate through the process and ensure your system works like new again.

Here’s a step-by-step approach to replacing the necessary components:

- Turn off the water supply: Before starting any repair work, make sure to shut off the water supply to prevent leaks or flooding during the replacement process.

- Disassemble the mechanism: Use appropriate tools to carefully remove the cover and access the internal components. Take note of the parts’ arrangement for reassembly.

- Identify the faulty components: Check for worn-out or damaged parts such as seals, valves, or other critical pieces that are affecting performance.

- Replace the damaged components: Remove the old parts and install new ones, ensuring they fit correctly and securely in place.

- Reassemble the system: After replacing the necessary components, carefully reassemble the unit and ensure everything is in its proper position.

- Test the system: Once everything is back together, turn the water supply back on and check the functionality. Ensure there are no leaks and that the flushing system operates smoothly.

By following these steps, you can replace any malfunctioning components and restore your system to optimal condition.