When maintaining a lawn mower, having a clear visual guide to the essential components can significantly simplify the repair and replacement process. A detailed representation of the machine’s structure helps identify each part’s function and location, ensuring that no vital element is overlooked.

Accurate identification of all key components is crucial for keeping the mower in optimal condition. By understanding the layout, you can avoid mistakes during repairs and ensure smooth functionality. This guide aims to assist owners in recognizing various components, which in turn will help improve both the performance and longevity of the equipment.

Whether you’re performing routine maintenance or addressing a specific issue, knowing where each part fits in the overall structure is an invaluable asset. This knowledge can save time, reduce unnecessary costs, and extend the mower’s lifespan.

Understanding the John Deere 212 Parts Diagram

In any piece of machinery, having a comprehensive visual reference for all its components is essential for efficient maintenance and repair. A clear schematic offers insight into the relationship between each element, helping users easily identify what needs attention or replacement. With this reference, you gain a better understanding of how each piece contributes to the overall operation.

By examining the detailed layout, it becomes easier to pinpoint the location of specific components and grasp how they interact. This knowledge is especially helpful when performing troubleshooting or routine servicing, as it enables faster diagnosis and reduces the chances of overlooking critical issues.

Whether you’re a novice or an experienced technician, this guide simplifies the complexity of equipment maintenance. With the right visual aid, tackling repairs becomes a more straightforward task, helping to avoid costly mistakes and ensuring that the machine continues to function at its best.

How to Identify Key Components on the Diagram

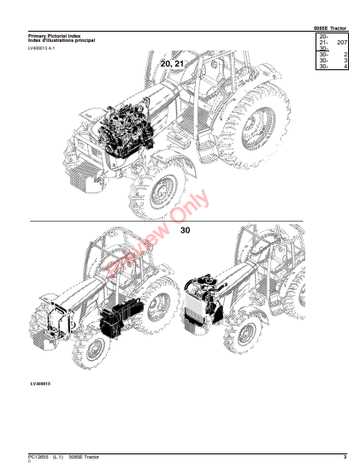

Recognizing essential elements within a schematic is the first step to effective maintenance and repair. A well-organized reference allows you to spot the parts you need to examine, replace, or troubleshoot, ensuring the machine runs smoothly. To make this process easier, it’s important to understand how to read and interpret the various symbols and labels presented in the visual guide.

Understanding Symbols and Labels

The diagram typically uses standardized symbols and clear labels to represent each individual part. Familiarizing yourself with these symbols is crucial for quick identification. Some diagrams may also include part numbers or descriptions, which help you match the parts with the correct specifications when ordering replacements.

Locating Key Parts in the Visual Representation

Once you understand the symbols, it’s time to focus on the major components that are critical for operation. These are often highlighted or positioned prominently in the visual guide. Pay close attention to areas related to the engine, transmission, and cutting mechanism, as these are typically the most essential for ensuring the equipment performs optimally.

Importance of Accurate Parts Replacement for Performance

Using the correct components during replacements is crucial for maintaining the optimal function of any machine. Even small discrepancies in size or design can lead to malfunctions, reduced efficiency, and increased wear. Ensuring that each element fits perfectly and operates as intended guarantees smoother performance and prolongs the life of the equipment.

When replacing a component, it’s essential to choose high-quality parts that meet the manufacturer’s specifications. This not only enhances performance but also prevents issues that may arise from using inferior or incompatible replacements. With the right parts in place, the equipment will run more efficiently, reducing the risk of costly repairs down the line.

Ultimately, accurate replacements contribute to the overall health of the machine, improving both its immediate performance and its long-term durability. Regular maintenance with proper parts ensures reliable operation, minimizing downtime and enhancing user satisfaction.