Tractors are complex machines with numerous interconnected elements, each playing a critical role in their overall functionality. Knowing how these components fit together is essential for effective maintenance and repairs. With proper understanding, owners can easily identify issues, improve longevity, and reduce downtime.

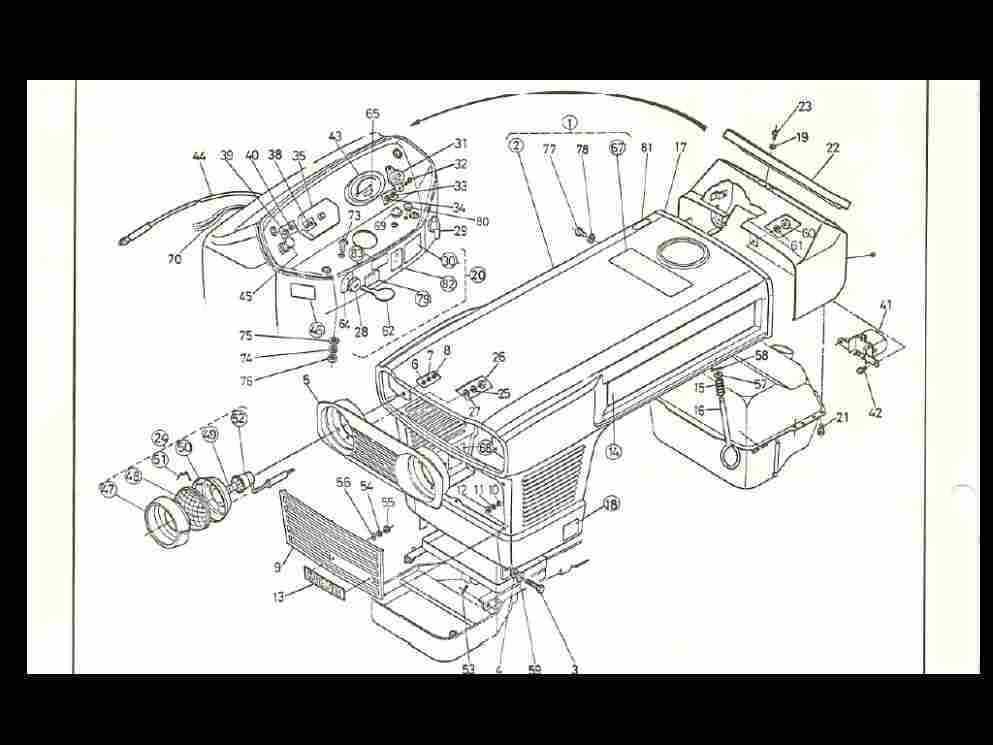

One of the most useful tools in this process is a detailed schematic that shows all the individual parts and their relationships within the system. These visual aids simplify the process of troubleshooting, allowing for quicker and more accurate repairs. Whether you are performing regular upkeep or tackling more complex problems, a clear overview of the system is invaluable.

By studying these breakdowns, users can not only repair issues more efficiently but also optimize the performance of their machinery. Regular attention to the mechanical structure ensures that tractors continue to operate smoothly and reliably for years to come.

Understanding the Kubota L2501 Components

Every piece of machinery is made up of numerous interconnected elements that work together to ensure smooth operation. Each component has its specific function, and understanding how they interact is key to maintaining the equipment’s efficiency. Identifying these parts and knowing how they function in unison helps owners perform better upkeep and avoid unnecessary breakdowns.

The engine, hydraulic system, transmission, and other vital mechanisms are all integrated into one unified structure. When one part malfunctions, it can impact the entire system. By having a clear understanding of each component’s role, users can easily detect potential issues before they escalate and cause more significant damage.

Knowing the structure of these key parts allows for easier identification of problems, especially when the machinery is in need of repair. Regular inspections and maintenance, when guided by a thorough understanding of the components, contribute greatly to extending the lifespan of the equipment.

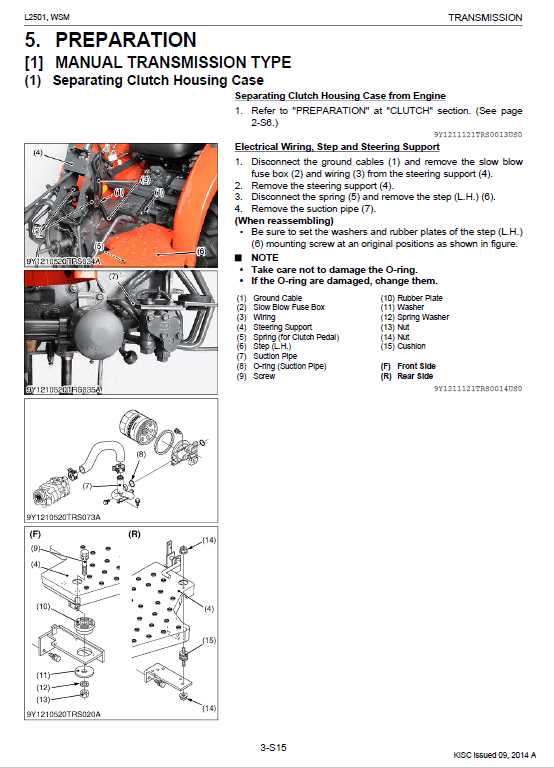

How to Read Kubota L2501 Parts Diagram

Understanding a machine’s layout can seem overwhelming at first, especially when faced with detailed visual representations. However, these schematics are invaluable tools that provide a comprehensive view of the system’s structure. Learning to read these illustrations effectively helps users identify and locate each individual component quickly, facilitating easier repairs and maintenance.

To read such a visual guide correctly, follow these steps:

- Identify key sections: A good schematic is divided into sections, often based on the system’s functionality–engine, transmission, hydraulic system, etc. Start by understanding which area of the machinery the diagram covers.

- Locate each part: Components are usually marked with unique numbers or codes. These identifiers correspond to a list or key, making it easy to find more information about each part.

- Understand the connections: Arrows and lines often indicate how parts are connected. Pay close attention to these to understand the flow of the system and how components interact.

With practice, these visual representations become easier to interpret, allowing you to diagnose issues more efficiently. Over time, the knowledge gained from reading these layouts becomes a valuable asset in maintaining machinery performance.

Common Maintenance Tips for Kubota L2501

Regular maintenance is crucial for keeping any piece of machinery in top condition. Preventative measures not only extend the lifespan of the equipment but also ensure it operates at peak performance. Understanding and following essential maintenance practices can help avoid costly repairs and minimize downtime during critical tasks.

Engine and Fluid Checks

One of the most important aspects of machinery upkeep is ensuring that the engine and its associated fluids are regularly inspected and maintained. Check the oil levels frequently and change the oil as recommended by the manufacturer. Clean the air filter regularly to ensure optimal airflow to the engine. Additionally, inspecting coolant and fuel levels will help prevent overheating or running out of essential resources during use.

Hydraulic and Transmission System Maintenance

Hydraulic and transmission systems play a vital role in the overall functionality of heavy equipment. Regularly inspect the hydraulic fluid and ensure there are no leaks. Pay attention to the performance of the transmission system by testing for smooth gear shifts and addressing any irregularities promptly. Performing these checks regularly helps maintain the efficiency of the machinery and prevents costly repairs in the future.